-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Allen‑Bradley PLC Compatible Modules: Complete Integration Guide

As a systems integrator who has lived through countless startups, retrofits, and midnight fault hunts, I’ve learned that “compatible” is not a label—it’s a test you pass on the plant floor. When you add compatible I/O, communication, motion, or safety modules to Allen‑Bradley controllers, your success rises and falls on a handful of practical factors: electrical match, network behavior, scan‑time impact, backplane capacity, and how well your software tools can identify, configure, and diagnose the device. This guide distills a field‑proven process for selecting, validating, and maintaining Allen‑Bradley compatible modules, with grounded perspectives from reputable sources and real‑world commissioning lessons.

What “Compatible” Really Means for Allen‑Bradley Systems

Compatibility isn’t one thing; it is an intersection of fit and function. The electrical layer has to match your supply and I/O levels; the mechanical layer has to mount cleanly and meet the available slot, chassis, or DIN rail constraints; the communication layer has to speak the same protocol and behave predictably under load; and the software layer has to recognize the module, expose the right parameters, and support diagnostics that your technicians can actually use. Add safety and environmental requirements, and you have the true definition of “compatible.”

There is also persistent confusion about whether a given controller classifies as a PLC or a PAC. Emerson explains that PACs generally offer more integrated architectures, broader language options, and advanced connectivity, while PLCs maintain a simpler model that remains effective for many systems. In practice, Allen‑Bradley CompactLogix and ControlLogix families behave like PACs in many applications, and MicroLogix aligns with more traditional PLC expectations. The takeaway is simple: treat “PLC versus PAC” as a capability spectrum, not a strict category, and size modules against the actual demands of your application rather than the label on the box.

Allen‑Bradley Controller Families at a Glance

| Family | Typical Role | I/O Scale | Primary Networks | Notes |

|---|---|---|---|---|

| ControlLogix | Plant‑wide, high complexity | High, modular chassis | EtherNet/IP; gateways for legacy | Suited to large systems, motion, and mixed specialty modules (Pacific Blue Engineering; R.L. Consulting) |

| CompactLogix | Machine‑level to mid‑size lines | Medium, compact and modular options | EtherNet/IP; remote I/O support | A versatile bridge between small machines and line control (Pacific Blue Engineering) |

| MicroLogix | Small, standalone machines | Low to moderate integrated I/O | Serial and basic Ethernet variants | Legacy and cost‑sensitive cases; plan for migration in many plants (Pacific Blue Engineering) |

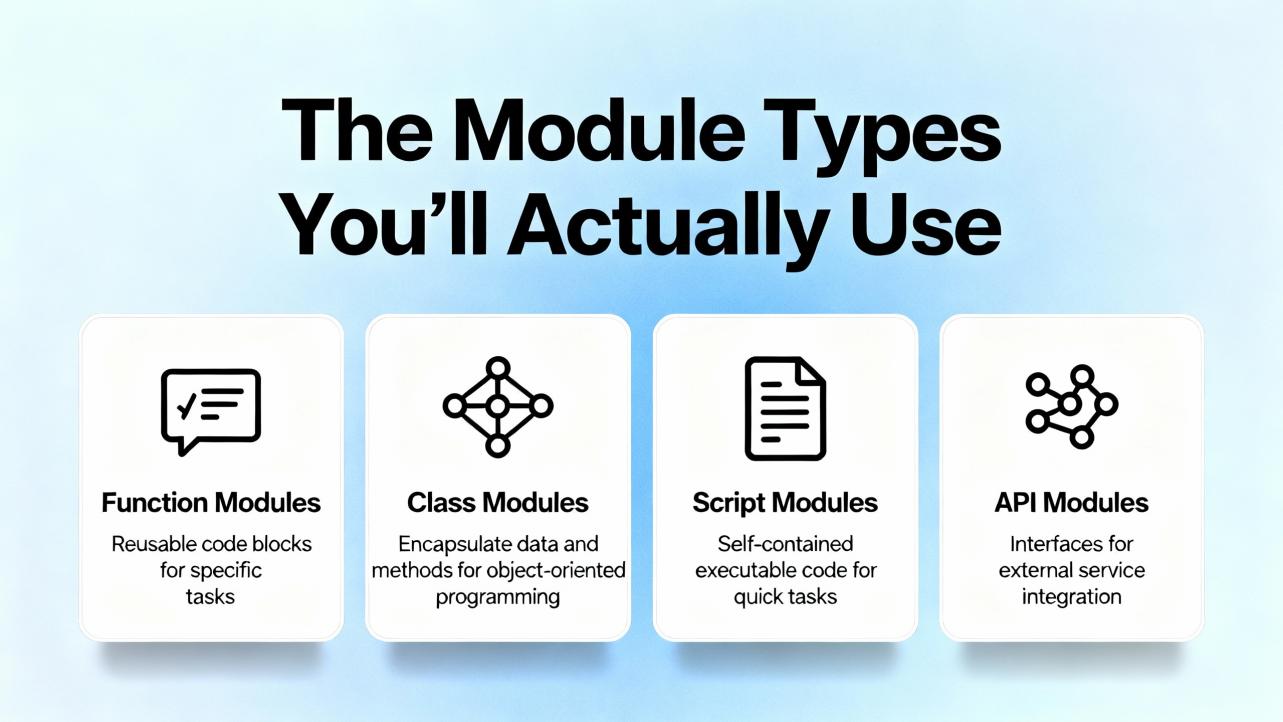

The Module Types You’ll Actually Use

Most projects lean on a familiar set of module types. Digital input and output cards handle on/off signals, and their real‑world success turns on whether they match the sinking/sourcing scheme used by your field devices. Analog input and output modules connect to transmitters and drives; getting the right ranges and isolation matters more than most teams expect because small noise becomes big drift in closed‑loop control. Specialty modules such as high‑speed counters and pulse‑width outputs enable precise motion and registration. Communication modules bridge controllers to drives, HMIs, and upstream systems; they must speak the right protocol and survive the electrical noise they will encounter. Safety I/O and safety controllers align with your risk assessments; their ratings, configuration method, and documentation must match your validation plan.

Shenzhen QIDA electronic CO.,ltd emphasizes that mismatched I/O specifications are a leading source of integration problems, and that aligns with what I see during site assessments: compatibility begins with a rigorous, point‑by‑point I/O match to field devices, not after you power up the panel.

Network and Protocol Fit: Where Compatibility Lives Day‑to‑Day

EtherNet/IP remains the dominant protocol around Allen‑Bradley controllers. Many plants still carry DeviceNet or PROFIBUS on installed equipment while newer layers add OPC UA for analytics. That mixed reality shows up on nearly every brownfield job. Emerson highlights the breadth of modern controller connectivity, and Shenzhen QIDA electronic CO.,ltd notes that a significant share of facilities runs legacy Fieldbus alongside newer stacks. If you read marketing that portrays every network as pure EtherNet/IP from end to end, treat it as aspirational. The most likely explanation for the disconnect is differences in region and installed‑base age. The practical path is to confirm what is actually in your plant network maps, then decide whether to bridge, segment, or migrate each segment.

With third‑party compatible modules, protocol conformance is only half the story. You also care about how the device behaves under stormy traffic, how it reports timeouts, whether it exposes diagnostics through your tools, and how it interacts with controller scan timing. If any of those unknowns feel risky, bench the module with your controller image and a realistic message load. A two‑hour test before the weekend beats a two‑day outage after it.

Electrical, Mechanical, and Environmental Fit

Allen‑Bradley ecosystems tend to standardize at 24V DC for control power and field I/O, with 120V AC still present in some plants for discrete devices. Maple Systems underscores the importance of matching supply and I/O levels, and that guidance applies doubly when you introduce compatible modules. Verify supply tolerances, channel current limits, and isolation ratings against your sensors and actuators. Confirm heat dissipation and spacing. Finally, treat environmental conditions seriously: vibration, electrical noise, and temperature fluctuations are routine in real cabinets, and modules that pass a quiet lab test can struggle in a hot mezzanine enclosure.

One subtle but valuable practice from Shenzhen QIDA electronic CO.,ltd is to separate high‑frequency communication modules from sensitive analog modules to reduce electromagnetic interference. In my experience, even a few inches of DIN rail spacing and a grounded divider can translate into clearer analog signals and fewer nuisance alarms. When a spec sheet claims high immunity, a quick analog noise trend recorded before and after reorganizing a row of modules is a simple way to verify the claim on your hardware.

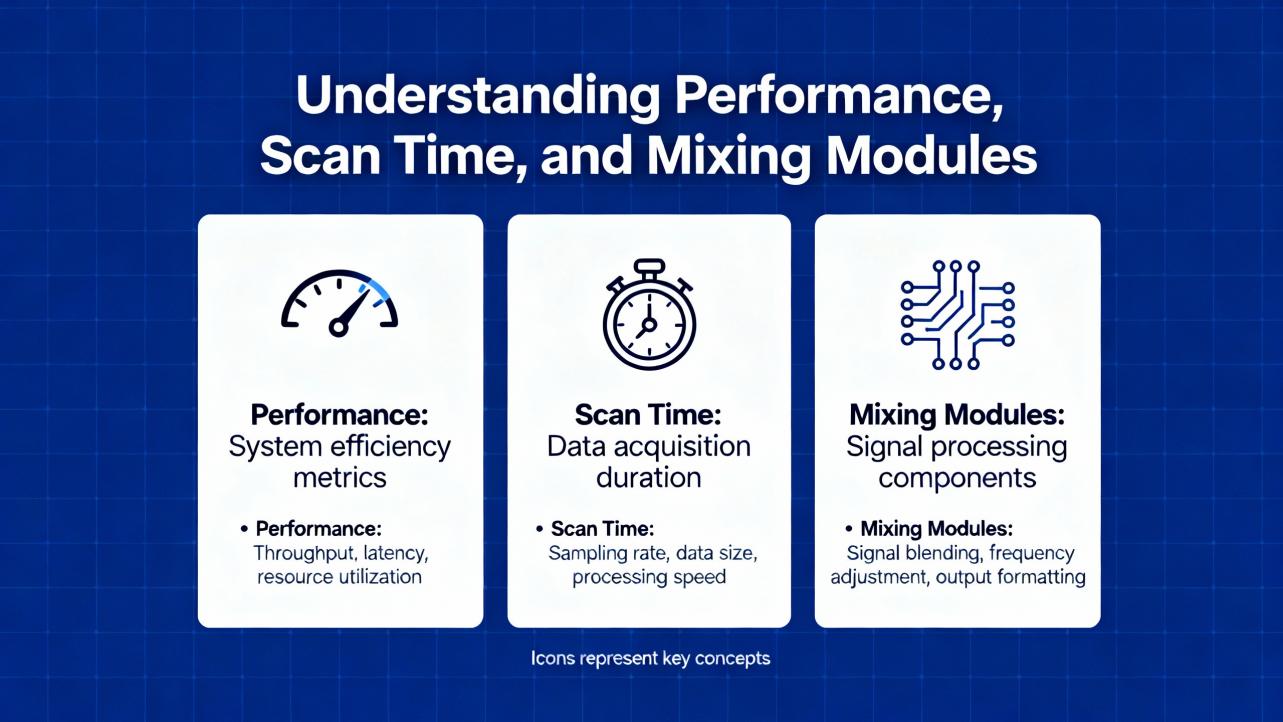

Performance, Scan Time, and Mixing Modules

Performance compatibility shows up as scan time, task jitter, and I/O response. Faster is not always better if jitter rises or a device’s buffer strategy does not match your control strategy. Shenzhen QIDA electronic CO.,ltd discusses scan and response characteristics at the module level and points out the very real effect of heavy logic, communications, and I/O load on controller cycles. On integrated machine controls, you can often hide that variability behind permissives and time filters. On coordinated line control and motion, you cannot. The remedy is to measure your base scan time, add modules in a bench test while streaming typical traffic, and watch the step changes. If you see more variability than your process can tolerate, move traffic to a lower priority task, offload to remote I/O, or pick a module with a more appropriate buffer model.

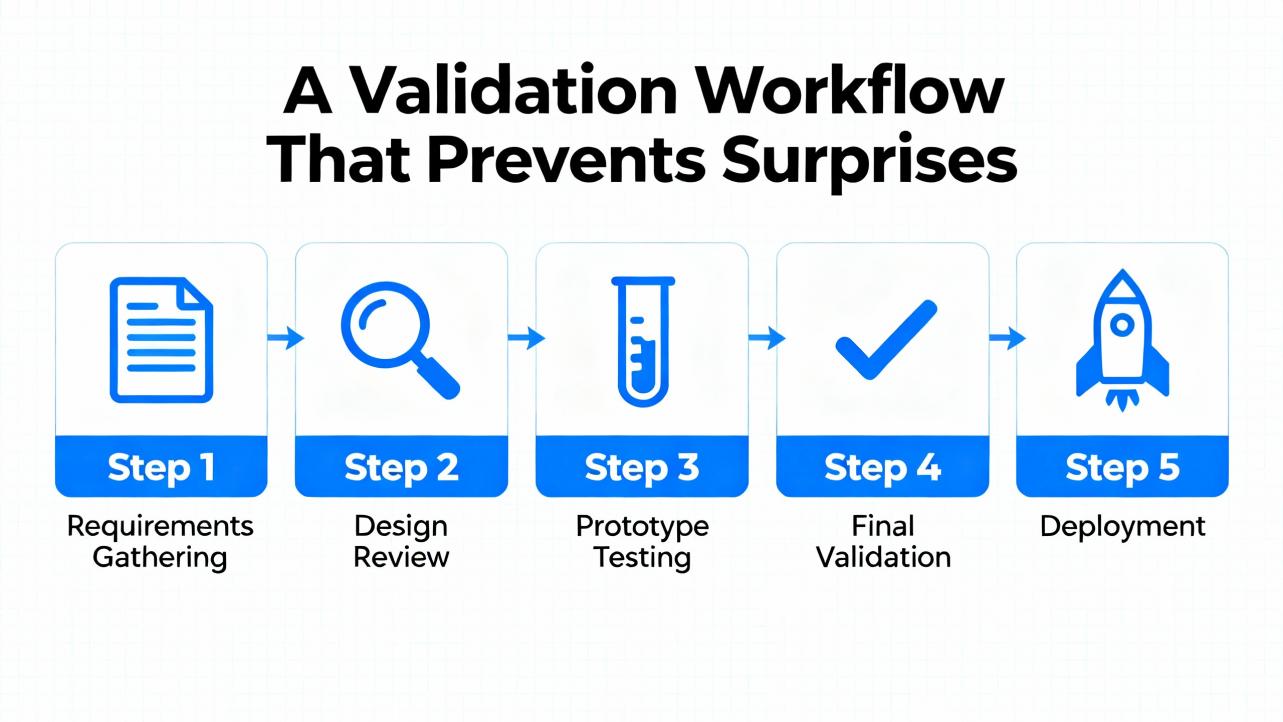

A Validation Workflow That Prevents Surprises

A reliable integration pattern has three stages. First, audit the existing system, beginning with a point‑by‑point I/O inventory and a live network map. This ensures every input and output has a real‑device match and that your protocol plan is grounded. Second, perform a bench test with the exact controller firmware and engineering workstation version you intend to use. The module should identify cleanly, expose configuration parameters you understand, and produce diagnostics your technicians can read. Even when a vendor claims drop‑in compatibility, a half‑day on the bench is prudent insurance.

Third, commission with a watchful eye. Tie your management of change to the panel drawing set and your module configuration. Build a trending view that captures controller scan time, key cycle timers, and any analog channels you modified. Maple Systems’ focus on diagnostics and documentation is exactly what pays dividends here; a module is only “compatible” if your team can troubleshoot it quickly during a shift change without guesswork.

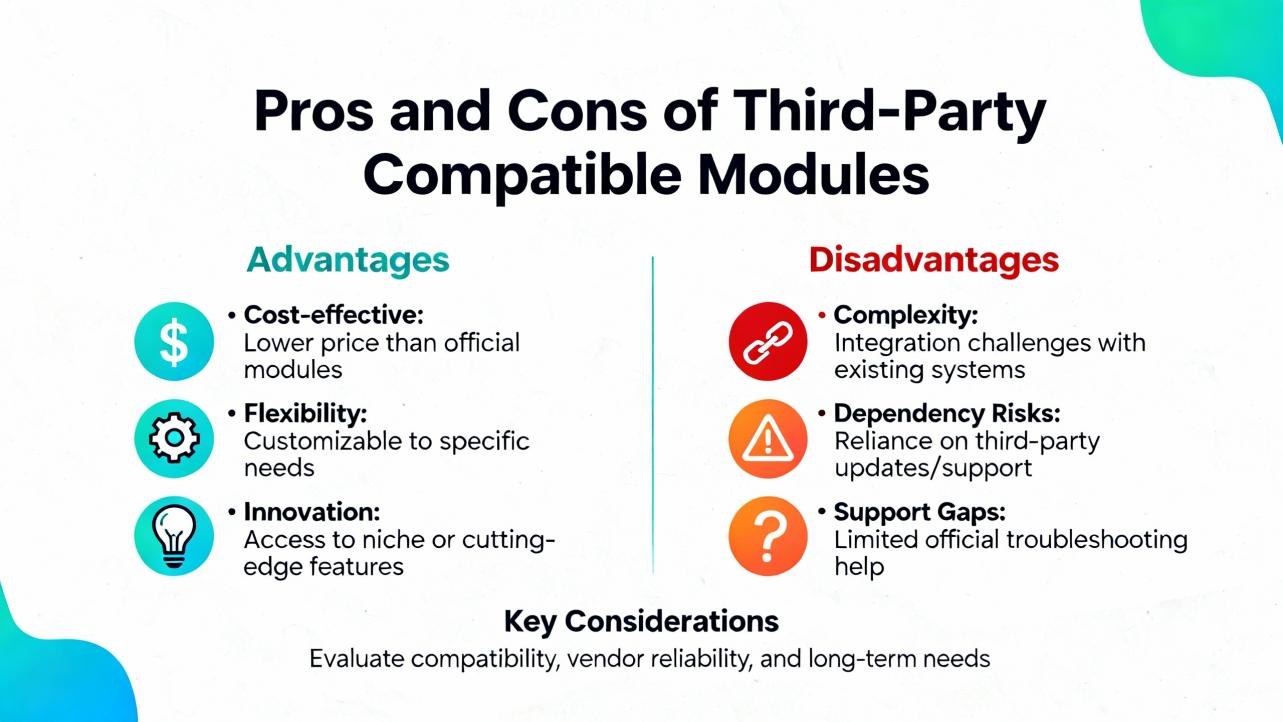

Pros and Cons of Third‑Party Compatible Modules

| Aspect | Third‑Party Compatible Module | Native Allen‑Bradley Module |

|---|---|---|

| Upfront cost | Often lower and competitive | Often higher |

| Features | Can offer niche or advanced features | Broad feature set aligned to ecosystem |

| Network options | Frequently strong on multi‑protocol support | Deep EtherNet/IP alignment |

| Tooling and diagnostics | Varies by vendor; validate up front | Predictable within the ecosystem |

| Support and spares | Dependent on vendor; check lead times | Strong channel support and stocking |

| Risk profile | Requires thorough bench testing | Lower integration risk in most cases |

Buying and Care Tips That Actually Reduce Risk

| Phase | What to Confirm | Why It Matters |

|---|---|---|

| Before purchase | Electrical levels, isolation, channel current, and power budget | Prevents nuisance trips and over‑current faults |

| Before purchase | Protocol behavior, diagnostics, and configuration options in your tools | Ensures your team can configure and troubleshoot |

| Before purchase | Mechanical fit: slot type, depth, terminals, and spacing | Avoids panel rework and hot‑spot heat issues |

| Before purchase | Environmental ratings and noise susceptibility | Sustains accuracy and uptime in real cabinets |

| During install | Separate noisy comms from analog; route shields intentionally | Reduces EMI‑induced drift and false trips |

| After commissioning | Trend scan time and analog noise; document module revisions | Catches regressions early; preserves serviceability |

Overlooked Insights You Can Put to Work

Some sources portray a clean break between Fieldbus and modern Ethernet. Shenzhen QIDA electronic CO.,ltd notes that many plants still run legacy DeviceNet or PROFIBUS alongside OPC UA and newer stacks, while vendor narratives sometimes imply a pure Ethernet future already in place. The differing conclusions likely arise from sample sets and the age of installed equipment. The practical move is to inventory your actual network segments, then decide where to bridge, segment, or modernize first rather than debating the ideal architecture in the abstract.

Another frequently cited claim is that most failures trace to I/O mismatches. Shenzhen QIDA electronic CO.,ltd reports high percentages for this failure mode. Maple Systems stresses compatibility and sizing discipline rather than a single root cause. Across plants I support, the apparent disagreement usually stems from how teams categorize failures; a blown field fuse caused by mis‑sized outputs “feels electrical,” but it can be logged elsewhere. Treat these percentages as directional. If you want certainty, pull the last year of downtime records and tag every event by field device, I/O card, network, and logic cause. An hour of categorization gives you data you can act on.

Finally, rules of thumb about spare capacity are valuable yet situational. Shenzhen QIDA electronic CO.,ltd recommends reserving around 30% spare I/O and 40% memory for growth. That is a solid starting point, but on a compact controller with limited slots it may be unrealistic. In those cases, an equally effective approach is to right‑size the base system and plan remote expansions over EtherNet/IP so you retain growth paths without over‑buying today. If you adopt that path, a quick proof with a remote I/O slice on your bench will confirm latency and determinism meet your process needs.

Cost and Lifecycle Considerations

Third‑party compatible modules can meaningfully reduce capital expense and improve feature fit, especially for specialized sensing, high‑speed counting, or protocol bridging. Shenzhen QIDA electronic CO.,ltd describes projects where modular expansions avoided controller replacements and delivered measurable savings. In my experience, those savings stick when two conditions hold: the vendor’s diagnostics integrate cleanly into your maintenance workflow, and spare parts are available within your planning window. A module that is cheaper to buy but costly to support will erase its advantage by the first extended outage.

Lifecycle cost also includes how upgrades unfold. Emerson describes safety controllers and edge‑ready industrial PCs that move data to on‑ or off‑premise systems for real‑time insights. If you’re pushing analytics or adding new safety functions over time, weigh how a module’s firmware update process, parameter backup, and recovery tooling fit your change‑management practices. The right choice is not merely the lowest price; it is the lowest risk of unplanned downtime over the years you plan to run the line.

A Step‑By‑Step Way to De‑Risk Integration

Start with application clarity. R.L. Consulting recommends matching controller class and I/O counts to the scale and complexity of your process, environmental conditions, and growth plan. From there, define the I/O map and reserve headroom for realistic growth. Map the network as it exists, not as you wish it were. Select modules that fit the real field devices and protocols you will run.

Then, prove it on the bench. Pacific Blue Engineering’s emphasis on competent integration echoes lived reality: a half‑day to validate identification, configuration, diagnostics, and load behavior is inexpensive insurance. Finally, commission with trend views in place and make documentation part of the job, not an afterthought. Maple Systems points to diagnostics, cross‑referencing, and documentation as force multipliers during maintenance; those are exactly what keep your compatible modules “compatible” after the original team moves on.

Quick Comparison: When Third‑Party Modules Make Sense

| Situation | Why Compatible Modules Win | What to Validate First |

|---|---|---|

| Specialized sensing or high‑speed counting | Features not available in native lineup | I/O levels, latency, noise immunity |

| Bridging mixed networks in brownfield plants | Multi‑protocol capability reduces re‑wiring | Conformance and behavior under load |

| Cost‑controlled expansions | Lower upfront cost and targeted capability | Tooling diagnostics and spares availability |

| Remote I/O additions for growth | Scalable without overhauling base controller | Determinism and scan‑time impact |

Frequently Asked Questions

What are the main Allen‑Bradley controller families I should plan around? ControlLogix serves large, complex systems with modular chassis; CompactLogix spans machine‑level to mid‑size line control with compact and modular options; MicroLogix targets smaller, standalone machines and is common in legacy upgrades. These roles are broadly described by Pacific Blue Engineering and echoed in field practice.

Do I need to standardize on EtherNet/IP to use compatible modules effectively? EtherNet/IP simplifies life around Allen‑Bradley controllers and should be your default for new work. That said, many plants still rely on DeviceNet or PROFIBUS in parts of the process. Emerson and Shenzhen QIDA electronic CO.,ltd both note mixed environments. Take a phased approach: bridge or segment where needed and migrate as downtime windows allow.

How much spare capacity should I reserve for future expansion? A reasonable starting point is to reserve roughly 30% I/O and 40% controller memory, as suggested by Shenzhen QIDA electronic CO.,ltd. If that level of headroom is impractical on compact hardware, plan remote I/O islands on EtherNet/IP so you maintain growth options without over‑sizing the base panel. A short bench test will confirm performance.

Are third‑party compatible modules reliable enough for safety functions? Safety requires conformance to your risk assessment and safety integrity targets. Emerson discusses safety controllers with established templates and ratings. When considering third‑party safety I/O, insist on clear certifications, assess how configuration and diagnostics integrate into your software, and validate safe‑state behavior during commissioning. If certification claims are unclear, run a witnessed test and document results before go‑live.

What is the single most common mistake when adding compatible modules? Rushing past the I/O and power match. Maple Systems stresses proper sizing and diagnostics, and Shenzhen QIDA electronic CO.,ltd points to I/O mismatches as a frequent failure mode. Always confirm voltage, current, isolation, and power budget at the channel and module level before you mount anything on the rail.

How do I avoid surprises with software recognition and diagnostics? Before purchase, ask the vendor to demonstrate how the module’s parameters and diagnostics appear in your engineering and runtime tools. On the bench, confirm the module identifies cleanly, parameters are settable, and alarms map to messages your technicians can interpret. If anything looks opaque, choose a different module or negotiate better documentation.

Takeaway

Compatible modules can transform Allen‑Bradley projects from constrained to capable while protecting budget and schedule, but only when compatibility is treated as a multi‑layer requirement and proven before production. Align electrical and environmental realities with the exact field devices you own. Match network protocols to the plant you have, not the one in a brochure. Measure scan time and behavior under load instead of assuming it will be fine. Favor modules whose diagnostics fit your maintenance workflow and whose spares you can actually stock. Reputable guidance from Emerson, Maple Systems, R.L. Consulting, Pacific Blue Engineering, and Shenzhen QIDA electronic CO.,ltd points in the same direction: disciplined selection, realistic bench testing, and clear documentation are what make “compatible” true on your line, shift after shift.

References

- https://admisiones.unicah.edu/scholarship/GGcvLV/5OK106/introduction__to-programmable__logic__controllers.pdf

- https://www.empoweredautomation.com/best-practices-for-implementing-automation-plc-solutions

- https://ch.farnell.com/a-comprehensive-guide-on-programmable-logic-controllers-trc-ar?srsltid=AfmBOoplGNDY7KaqEPDsuUWZeysruw3hoPbz8aUv1e9OqmjSGa9tTPpM

- https://compatibility.rockwellautomation.com/

- https://greenpegltd.com/types-of-allen-bradley-plcs-a-comprehensive-guide/

- https://maplesystems.com/10-things-to-consider-when-choosing-new-plc/?srsltid=AfmBOophChrLCmjGoXjLXaRuwEpvY2d4jn2fOHC8kxcqzjhzyYW9aVff

- https://pacificblueengineering.com/integrating-plcs-with-plc-experts/

- https://info.premierautomation.com/blog/8-practices-for-specifying-plcs-pacs-or-pc-controllers

- https://www.qidaautomation.com/blog/how-to-select-matching-plc-modules-for-automation-projects

- https://www.realpars.com/blog/allen-bradley-plc-types

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment