-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Allen‑Bradley PLC‑5 Obsolete Parts: Legacy Platform Support Solutions

Introduction

The PLC‑5 built the modern plant floor. From wastewater networks and energy sites to packaging halls and remote process lines, thousands of systems still rely on the stability of this Allen‑Bradley workhorse. Rockwell Automation discontinued new PLC‑5 systems in June 2017, and the surrounding ecosystem of 1771 I/O, DH+, RIO, and ControlNet has continued to age. If you are maintaining a PLC‑5 today, you are balancing asset life extension, parts scarcity, safety, and migration planning—often while production must keep running. This article lays out a pragmatic, field‑tested playbook to source obsolete PLC‑5 parts responsibly, keep aging systems safe and maintainable, and migrate on a timeline that fits your budget and outage windows.

I write from the vantage point of a veteran systems integrator and reliable project partner who has supported PLC‑5 across energy, water, and discrete manufacturing programs. What follows blends hands‑on experience with reputable guidance from Rockwell Automation, CrossCo, Avanceon, Hallam‑ICS, Crossroad Energy Solutions, Industrial Automation Co., the Oxmaint community, and others. Where inference is necessary, I state it explicitly and rate my confidence.

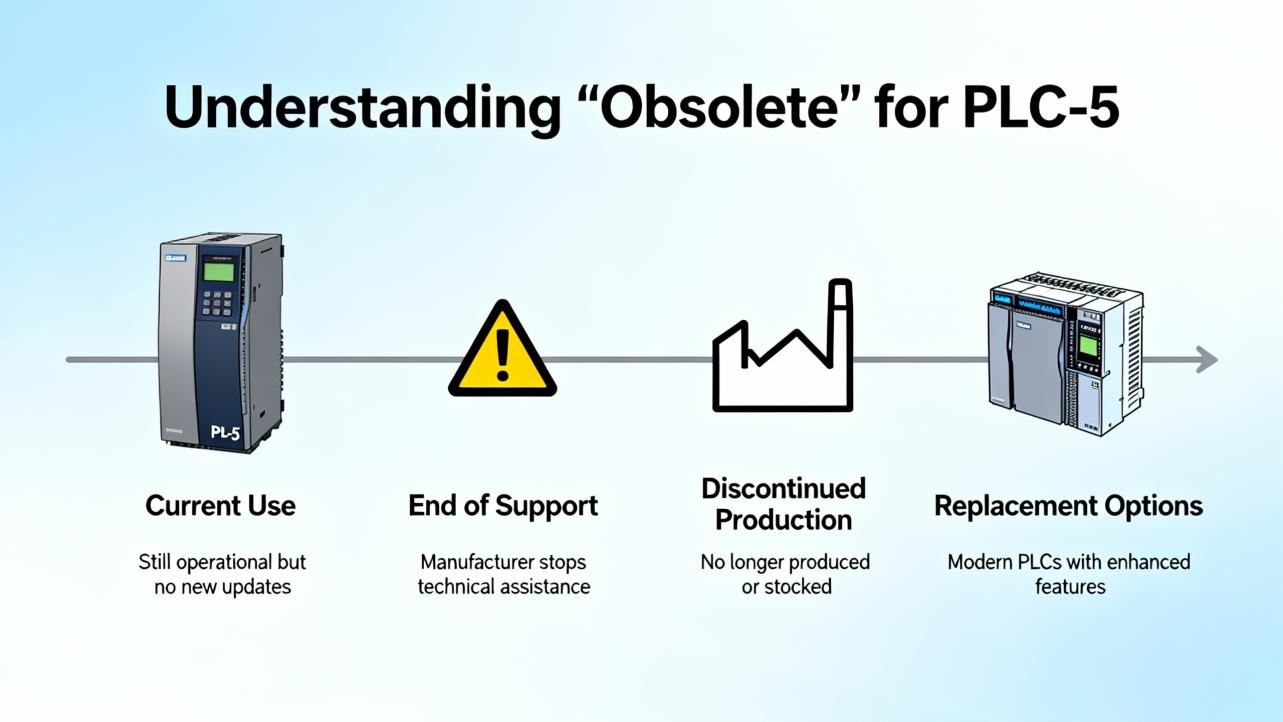

What “Obsolete” Means for PLC‑5

Obsolescence in industrial control is not simply an end‑of‑sale date. It is a lifecycle reality where new hardware stops shipping, factory support winds down, qualified repair channels thin out, compatible modules disappear from primary channels, and the remaining stock migrates to secondary markets at unpredictable quality and price. For the PLC‑5, Rockwell Automation’s official discontinuation date in June 2017 is the anchor. Based on Rockwell Automation statements and CrossCo commentary, you should assume new units are no longer for sale, and plan accordingly.

The installed base is large. Crossroad Energy Solutions cites an estimated 450,000 platforms deployed at peak. From my field perspective, that figure aligns with the daily reality that many plants still have at least one PLC‑5 rack somewhere on site, often running stable code tied to older MCCs, packaged equipment, or remote I/O trains. As for the original introduction date, sources differ between the mid‑1980s and late‑1980s; most put it at 1986. I rate that timing as high confidence, acknowledging some sources cite 1988.

Why PLC‑5 Systems Persist

The persistence is logical. PLC‑5 systems earned their keep with robust uptime, modularity, and a mature support skill set built inside maintenance teams. Many controllers were tucked into OEM machines with minimal post‑install changes. Plants often improved around them—new VFDs, instrumentation, and HMIs—while keeping the core logic intact. The result is equipment still doing its job while spare parts become harder to find, related protocols approach their own end‑of‑life, and younger technicians are trained on Studio 5000 rather than RSLogix 5.

The Risk Landscape When Parts Age Out

Obsolescence risk shows up in several ways. Scarcity inflates lead times and prices, especially for clean 1771 I/O modules or Ethernet‑enabled PLC‑5 processors. Some parts are only available refurbished or as “new old stock” from secondary markets; both can be excellent options when tested and warranted, but both require diligence. Communication cards and networks are part of the risk picture too. ControlNet and RIO have been aging in step with 1771 hardware, and skills for DH+/RIO bridging are rarer each year. The net effect is longer recovery times during a failure event.

Unplanned downtime remains expensive. Industrial Automation Co. cites a widely used benchmark near $5,600.00 per minute for certain sectors. Your plant’s figure may be lower or higher; the takeaway is that a predictable plan beats improvising during a midnight failure.

How to Verify Lifecycle Status and Compatibility

You cannot manage what you cannot see. Rockwell Automation’s Product Lifecycle Status and the Product Compatibility and Download Center are the authoritative sources for lifecycle and compatibility. Practically, entering the first digits of a catalog number in the compatibility center helps pivot from one part to the broader family view. I require teams to verify firmware availability, compatibility of replacement sub‑revisions, and any network protocol implications when a module is substituted. The Oxmaint community’s note on sudden obsolescence of unexpected 5069 models is a good reminder that even newer platforms can move through lifecycle phases quickly; always verify before you standardize.

Essential Definitions and Acronyms

| Term | Definition |

|---|---|

| PLC‑5 | Legacy Allen‑Bradley programmable logic controller family using 1771 I/O and file‑based addressing. |

| ControlLogix (Logix 1756) | Rockwell Automation’s modern tag‑based platform recommended for PLC‑5 migration. |

| SLC‑500 | A smaller legacy platform now nearing end‑of‑life in many variants. |

| DH+, RIO, ControlNet | Legacy PLC‑5 era networks; many sites now prefer EtherNet/IP. |

| EtherNet/IP | Modern IP‑based industrial protocol standard on Logix platforms. |

| FEED Study | Front End Engineering Design: a structured assessment to define migration scope, risks, costs, and schedule. |

| MCC | Motor Control Center; the electrical hub for motor feeders and starters. |

| Packaged Plant | Vendor‑supplied subsystem integrated into site controls; often tied to legacy interfaces. |

| NOS | “New old stock”: unused items from earlier production runs. |

| Migration vs Upgrade | Migration minimizes functional change; upgrade adds new capabilities. Both are valid strategies depending on constraints. |

Lifecycle and Migration Facts at a Glance

| Topic | Practical Note | Source Confidence |

|---|---|---|

| Discontinuation | PLC‑5 discontinued June 2017; plan for diminishing primary‑channel parts. | High (Rockwell Automation, CrossCo) |

| Installed Base | Approximately 450,000 units at peak deployment. | Medium‑High (Crossroad Energy Solutions) |

| Introduction Date | Mid‑to‑late 1980s; most sources cite 1986. | High (CrossCo, Crossroad; Avanceon notes late‑80s) |

| Recommended Successor | Migrate to ControlLogix; CompactLogix paths exist for smaller scopes. | High (Rockwell Automation, Crossroad Energy Solutions, community practice) |

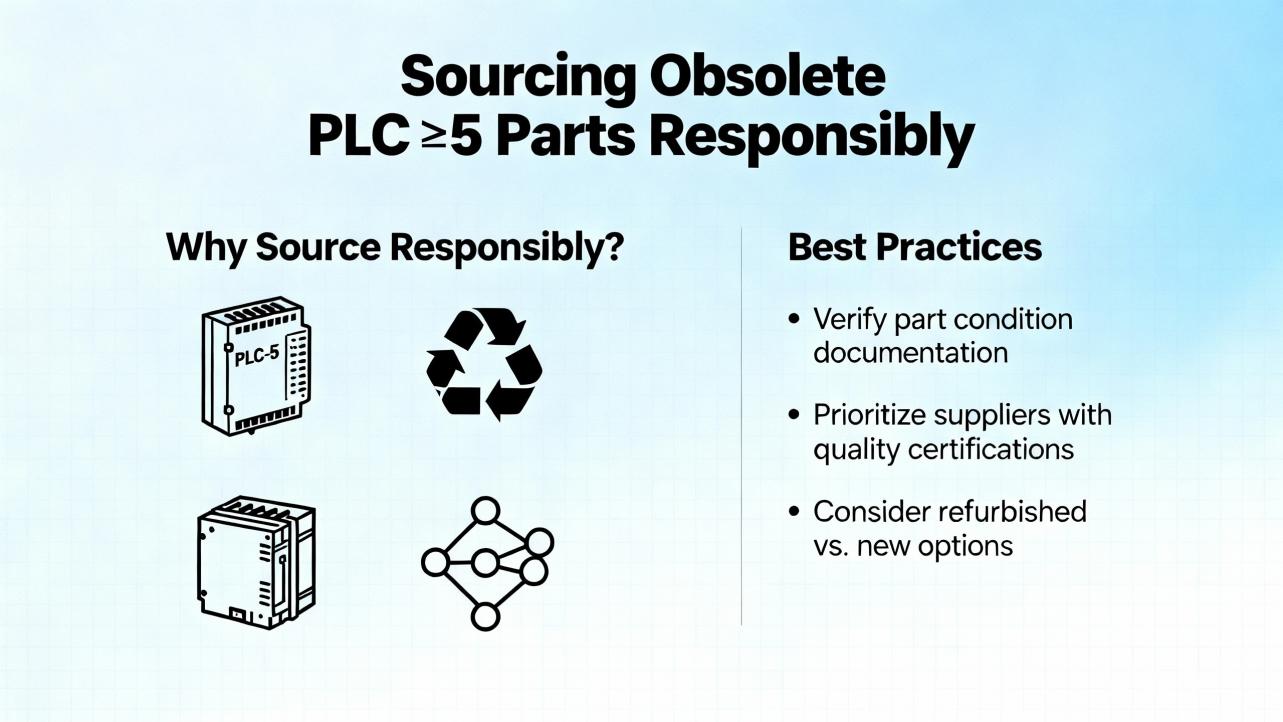

Sourcing Obsolete PLC‑5 Parts Responsibly

Responsible sourcing is a repeatable process, not a gamble. Start by documenting exact part numbers, revisions, firmware levels, and required network interfaces. Request test reports and functional verification from the supplier, and insist on a clear warranty. Industrial Automation Co. emphasizes multi‑point testing and substantial warranty windows; that level of assurance materially lowers your risk of dead‑on‑arrival hardware. For refurbished items, I ask for evidence of board‑level repairs, burn‑in tests, and communication checks. Audit the seller’s traceability and return policy, and be suspicious of prices far below market without proof. This due diligence helps avoid counterfeits and under‑tested modules that can strand your line.

Secondary markets, surplus programs, and buyback channels are part of a healthy support strategy. Several reputable suppliers specialize in obsolete Allen‑Bradley parts and can locate hard‑to‑find 1771 modules or PLC‑5 processors. Buyback programs let you turn decommissioned assets into credit for spares or migration hardware. Platforms like Hasuka Automation and Industrial Electrical Warehouse discuss how to vet stock condition, confirm real‑time availability, and avoid broker relisting pitfalls. The goal is to keep your storeroom ready without tying up budget in dead inventory.

Care of Installed PLC‑5 Assets While You Plan

Plants can safely extend life while preparing to migrate. Maintain verified backups of PLC programs, comments, and I/O maps, plus any custom scaling or PID settings. Replace lithium batteries proactively and schedule periodic power‑ups for stored spares to avoid capacitor degradation. When a plant must continue on PLC‑5 for several quarters or years, I recommend rotating refurbished spares through bench power‑up cycles and communication checks every quarter. Keep a complete, current set of as‑built drawings and cause‑and‑effect matrices; they are invaluable when the team must swap a module under time pressure. This care plan keeps your risk manageable while you move toward a modern platform.

Legacy Networks and Bridging Strategy

Bridging legacy and modern networks enables phased cutovers that fit tight outage windows. The PLC‑5 world often includes DH+, RIO, and ControlNet. Logix controllers can bridge to those networks using appropriate modules and transition tools, allowing you to stage the migration one rack or subsystem at a time. In many sites, older PLC‑5 processors feed multiple remote I/O racks; a bridge‑first strategy lets you shift the processor and HMI to ControlLogix while leaving I/O in place, then convert the I/O trains over planned outages. This pattern reduces risk and creates clean rollback paths if commissioning finds unexpected edge cases.

| Legacy Network | Typical Modern Approach | Migration Note |

|---|---|---|

| DH+ | Bridge to EtherNet/IP via Logix communication modules | Useful for staged processor swaps while maintaining legacy nodes. |

| RIO (1771) | Reuse field wiring with wiring conversion kits and 1756 I/O | Minimizes rewiring and reduces panel rework risk. |

| ControlNet | Migrate to Ethernet where feasible | Plan for SCADA updates and deterministic timing considerations. |

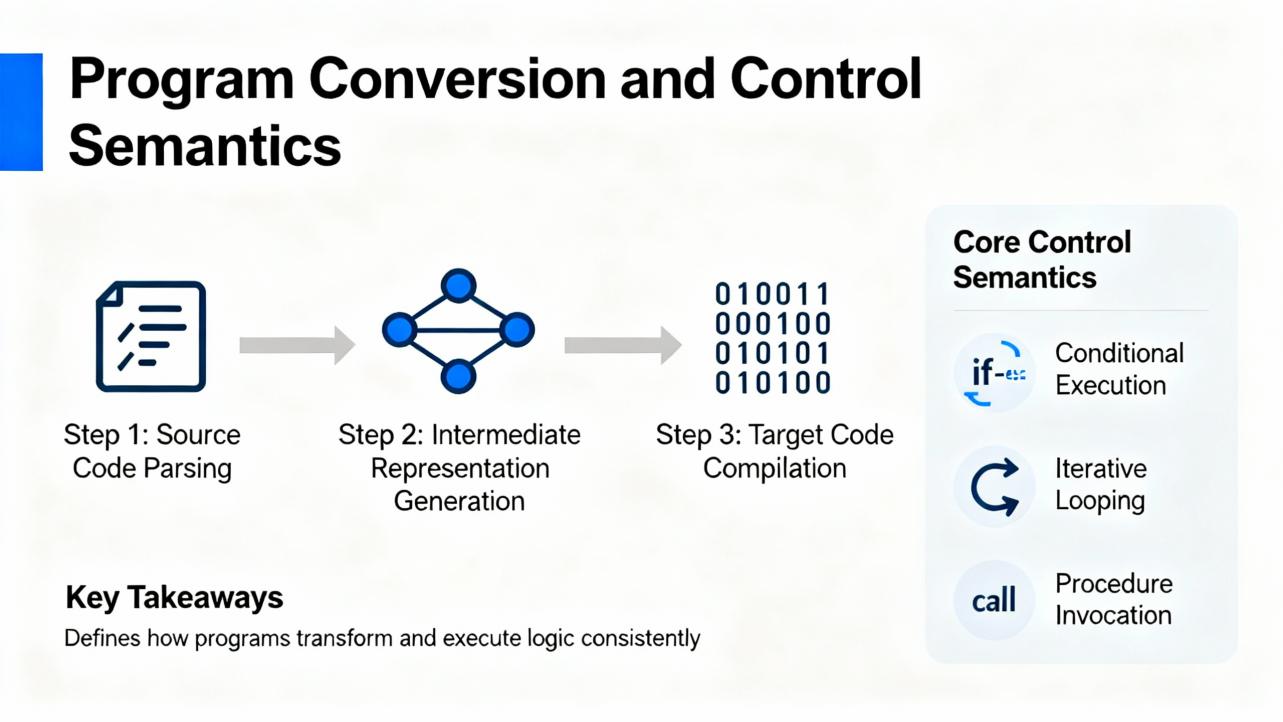

Program Conversion and Control Semantics

Code migration is as much about clarity as it is about function. RSLogix 5 file‑based addressing often carries octal addressing artifacts; conversion tools can import the PLC‑5 logic into Studio 5000, but the result usually needs cleanup. In my teams, we remove dead code and octal alias references, rationalize tag names to language that matches P&IDs and HMI labels, and convert repeated constructs into user‑defined data types and function blocks. You should also reconcile 16‑bit PLC‑5 arithmetic versus 32‑bit Logix behavior, particularly in areas with indirect addressing or array operations. A detailed test plan, simulation of interlocks, and a written rollback procedure are standard practice for clean cutovers.

Field‑Proven Migration Patterns

Several integrators have documented multi‑year, low‑downtime conversions. Hallam‑ICS describes phasing a large installed base by piloting a mid‑sized subsystem first, validating the conversion toolchain, and refining the workflow before tackling the largest trains. Their teams leveraged Rockwell 1771‑to‑1756 wiring conversion hardware to reuse field terminations, built custom cables where channel counts differed, and ran parallel SCADA where appropriate to confirm functional equivalence before cutover. In another case, a controls team used a portable PLC and I/O logging to reverse engineer a locked legacy controller, reconstructing behavior on modern hardware without source code access; Hale Engineering & Consultancy highlights this method as a time‑saver when documentation is missing.

The Case for a FEED Study

A constrained outage window and a wide set of legacy interfaces are exactly why a Front End Engineering Design study pays for itself. A good FEED documents the as‑is state, ranks risks, scopes phased cutovers, and produces a bill of materials and schedule credible enough to align maintenance, operations, and finance. CrossCo emphasizes quantifying downtime exposure in dollars, which helps leadership rationally weigh a planned migration against gambling on repairable failures. The FEED also surfaces non‑PLC risks such as very old HMIs or DOS‑era PCs that could block an otherwise clean processor swap.

Stay Versus Migrate: A Pragmatic Comparison

| Consideration | Keep PLC‑5 Operational | Migrate to Logix Platform |

|---|---|---|

| Downtime Risk | Acceptable if strong spares, skilled techs, and short recovery | Reduced via modern diagnostics and vendor support |

| Parts Availability | Secondary markets, refurbished/NOS, rising prices, variable lead times | New hardware, standard channels, predictable supply |

| Skills and Tools | Fewer new techs trained on RSLogix 5; legacy protocols | Widespread skills, Studio 5000, contemporary networks |

| Safety and Compliance | Manageable with disciplined documentation and change control | Easier to maintain with modern platforms and HMIs |

| Cost and Phasing | Lower near‑term spend; risk accrues over time | Higher upfront; can phase by area and spread costs |

| Future Integration | Limited by DH+/RIO/ControlNet and 1771 I/O | Native EtherNet/IP, modern diagnostics, data integration |

This decision is rarely binary. Many sites adopt a hybrid path: stabilize the PLC‑5 with curated spares and disciplined backups while executing phased migrations on the highest‑risk lines first.

Buying Tips for Obsolete PLC‑5 Parts

Careful procurement prevents surprises. Ask for functional test reports specific to your module, not a generic statement. Confirm warranty terms in writing, and understand whether the warranty is repair‑or‑replace. Match the catalog number, series, and firmware to your slot and backplane assumptions. Check for battery health on processor modules and ask whether NVRAM contents are preserved or wiped. Request high‑resolution photos for terminal and backplane pins to spot mechanical stress. Verify the seller actually holds stock rather than brokering from other sellers, and ask about same‑day shipping when downtime is at stake. If cost and schedule allow, buy two spares for the truly line‑critical positions—the second can live on a powered test bench, ensuring one unit is always ready.

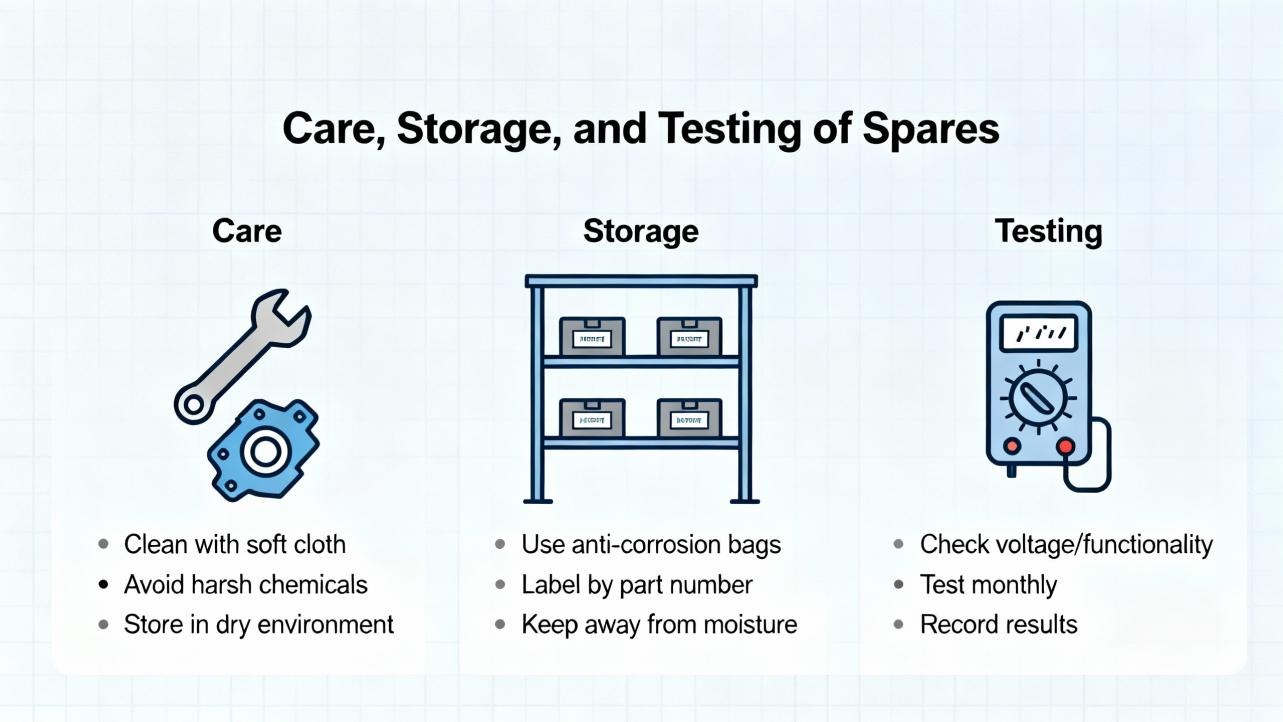

Care, Storage, and Testing of Spares

Electronics age on the shelf. Keep spares in ESD‑safe packaging with desiccant. Store in a temperature‑controlled area and periodically power up modules per manufacturer guidance. For communications cards, include a simple bench test with a known‑good node to verify link integrity. Log every test with date, tester, and results, and set reminders to rotate test duty. That discipline reduces the chance of installing a spare that fails to boot at the worst possible moment.

Budgeting and the Business Case

Downtime cost is the lever that turns executive attention into budget. Industrial Automation Co. references a widely cited figure near $5,600.00 per minute for certain manufacturing environments. Even if your plant’s true number is half that, a single multi‑hour event can justify a phased migration. A defensible business case will outline the installed base, the cost to stabilize with spares and documentation, the cost to migrate by area, the expected outage windows, and the impact on safety and product quality. I recommend including supply chain risk explicitly; COVID‑era disruptions and rapid product lifecycle changes have made long lead times a recurring theme even for newer platforms.

Where PLC‑5 Still Fits in a Modernization Plan

Some lines do not merit immediate modernization. In those cases, I treat PLC‑5 as a stable island with a hardened perimeter: refresh the HMI if it is the highest risk, keep SCADA current enough to support alarm rationalization and data logging, and bridge the network to EtherNet/IP to simplify future integration work. ATSYS highlights the importance of scoping across switchboards, MCCs, and packaged plant interfaces so you do not strand a new processor behind outdated subsystems. Plan the interfaces as much as the controller change.

Quick Reference: Responsible Sourcing and Migration Steps

| Area | High‑Value Action | Why It Matters |

|---|---|---|

| Lifecycle Verification | Check Rockwell lifecycle and compatibility for every catalog number | Prevents dead ends and incompatible substitutions |

| Documentation | Maintain backups, I/O maps, cause‑and‑effect, and as‑builts | Cuts recovery time and de‑risks migration |

| Spares Strategy | Stock tested, warranted CPU, power, I/O, and comms | Shortens outages; avoids counterfeit pitfalls |

| Bridging Plan | Bridge DH+/RIO/ControlNet to EtherNet/IP | Enables phased cutovers and clean rollback |

| Code Strategy | Clean conversion output, modernize tags and UDTs | Improves maintainability and troubleshooting |

| FEED Study | Quantify risk, scope phases, align costs and outages | Turns a risky project into an executable plan |

First‑Hand Lessons Learned

One lesson appears again and again: practice the swap. We assemble racks offsite, load the migrated program, connect a simulated I/O bench, and run a full FAT before a single wire moves on the plant floor. That dry run catches 90 percent of surprises. Another lesson is to standardize conversion hardware and repetitively train a small swap team; two technicians who have practiced together will avoid wiring errors and move quickly, as noted in the Hallam‑ICS case study. Finally, I have learned not to over‑optimize the first pass. Migrate for functional parity first; layer in architecture improvements and analytics after the process is stable on the new platform.

Brief Source Notes

Rockwell Automation provides the authoritative lifecycle position and migration resources for PLC‑5, and is the primary reference for discontinuation and successor guidance. CrossCo and Avanceon offer practical migration considerations and code‑level advice, including pitfalls with octal addressing and 16‑bit to 32‑bit semantics. Hallam‑ICS documents multi‑year conversions with measurable downtime discipline and effective use of wiring conversion kits. Crossroad Energy Solutions quantifies the installed base and reinforces the June 2017 end‑of‑support reality. Industrial Automation Co., Industrial Electrical Warehouse, and Hasuka Automation provide actionable sourcing and testing guidance for obsolete parts, while the Oxmaint community highlights the importance of continuous lifecycle checks even for newer families.

FAQ

Is the PLC‑5 still supported?

New PLC‑5 units are discontinued, and formal vendor support has winded down since June 2017. You can still obtain parts through refurbished and new old stock channels, and many integrators support migrations and life‑extension programs. Rockwell Automation publishes lifecycle and migration resources to help plan the transition.

Can I migrate without tearing out all my 1771 I/O?

Yes. A phased approach is common. Bridge DH+/RIO/ControlNet as needed, move the processor and HMI to a Logix platform first, and then convert I/O racks over planned outages using wiring conversion kits to reuse field terminations. This approach shortens downtime and offers a clean rollback path.

Do I need to rewrite my entire PLC‑5 program?

Not necessarily. The standard pattern is to import PLC‑5 logic with the Rockwell conversion tool and then clean the result. That cleanup typically includes removing octal artifacts, modernizing tag names, restructuring repeated logic with user‑defined data types or function blocks, and reconciling 16‑bit to 32‑bit arithmetic differences. Full rewrites are reserved for cases where conversion yields unclear or brittle code.

How do I avoid counterfeit or under‑tested obsolete parts?

Buy from suppliers who provide module‑specific test reports, clear warranty terms, and real photos of the unit you are purchasing. Confirm they physically hold the item and can ship the same day. Ask about refurbishment steps, bench testing, and communication checks. A price that looks too good often lacks test evidence.

What if my legacy controller is locked and I cannot export the code?

Data‑driven reverse engineering is viable. Teams can connect a portable PLC and log I/O traffic to reconstruct behavior on modern hardware. Hale Engineering & Consultancy details this approach, which cuts manual reverse engineering time when documentation is scarce.

How do I justify the cost of migration?

Quantify downtime in dollars for your process, factor in parts scarcity and lead‑time risk, and present a phased plan that matches outage windows. A widely cited benchmark is about $5,600.00 per minute for certain manufacturing environments. Pair that with a credible FEED study to turn the conversation from fear to execution.

Takeaway

The PLC‑5 earned its legacy by running reliably for decades, and many plants still depend on it. The challenge is not whether it has served well—it has—but how to responsibly support it as parts grow scarce and then migrate without disrupting production. Verify lifecycle status, curate tested spares with solid warranties, and practice disciplined documentation and bench testing to stabilize the present. In parallel, plan a phased migration: bridge legacy networks, reuse field wiring with conversion kits, clean imported logic, and run full offsite FATs before cutover. With that pragmatic playbook, you can keep your line safe today and arrive at a maintainable, modern control platform on your terms rather than a failure’s terms.

References

- https://peer.asee.org/efficient-way-of-converting-outdated-allen-bradley-plc-5-system-into-modern-controllogix-5000-suit.pdf

- https://www.researchgate.net/publication/378014896_Efficient_Way_of_Converting_outdated_Allen_Bradley_PLC-5_System_into_Modern_ControlLogix_5000_suit?_share=1

- https://www.amplio.com/post/sell-allen-bradley

- https://hale-eng.co.uk/revitalising-industrial-operations-obsolete-plc-reverse-engineering-and-upgrade-case-study/

- https://atsys.com.au/case-studies/case-study-hallet-cove-wastewater-network-upgrade-6

- https://crossroadenergy.com/allen-bradley-plc-5-upgrades/

- https://www.hallam-ics.com/blog/plc5-to-controllogix-conversions-a-multi-year-conversion-case-study

- https://community.oxmaint.com/discussion-forum/complete-guide-to-allen-bradleys-obsolete-plc-models

- https://www.avanceon.com/blogs/upgrading-plc5/

- https://www.cates.com/industrial-automation-system-integrators/plc-5-upgrades/

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment