-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Emergency PLC Parts Delivery: Fast Solutions for Critical Downtime

When production stops, the right part delivered at the right hour is the difference between a contained incident and a lost shift. Speaking as a systems integrator who has fielded those 2:00 AM calls on packaging lines, steel mills, and converting plants, speed is not just about shipping. It’s about knowing precisely what to ask for, choosing the best available substitute when the exact part is unobtainable, and having your program, firmware, and safety assumptions prepared so the replacement actually brings the line back. This article explains how to build that capability with a focus on practical steps, realistic lead times, and the choices that shorten downtime without introducing new risks.

What “Emergency PLC Parts Delivery” Really Means

Emergency PLC parts delivery is the coordinated process of specifying, sourcing, and receiving critical control components on a same‑day or overnight basis to restore production. It includes PLC CPUs and modules, drives and drive accessories, HMIs and operator panels, industrial power supplies, communication adapters, and the support gear that connects them. Fast delivery is enabled by a mix of supplier programs, distributor inventory, and stocking dealers. Emerson’s QuickShip program emphasizes fast, reliable fulfillment that leverages global infrastructure and local presence to help facilities avoid downtime and control costs. In practice, “fast” depends on what is physically in stock and how well your request is specified. A vague part request creates delays even when the warehouse is next door; a precise request can turn a distant shelf into a same‑day solution.

Where Downtime Starts: The Real Failure Points

In downtime triage, certain components consistently sit at the top of the risk stack. Industrial Automation Co. highlights VFDs and servo drives, PLC CPUs and I/O modules, HMI panels, and the “silent” support items such as power supplies, contactors, and cabling. A practical way to translate that into action is a tiered spare strategy aligned to impact. Tier 1 parts are those that halt production if they fail, Tier 2 parts can be worked around for a time, and Tier 3 parts carry lower risk but still create headaches during skeletal holiday staffing.

A clean way to make the tiers real is to review 12–18 months of maintenance history and isolate repeated failures and single points of failure. If the same analog input card has thrown intermittent faults twice this year, treat it as a future downtime candidate. If one HMI runs a batch manager without a second operator station, it is a single point of failure. This is not theory; it’s a pattern that shows up in maintenance logs facility after facility.

| Tier | Definition | Typical examples | Action to prepare |

|---|---|---|---|

| Tier 1 | Failure stops the line | PLC CPU, primary VFD or servo drive, main HMI | Keep a tested spare; document firmware; pre‑stage config backups |

| Tier 2 | Workaround possible but risky | I/O modules, auxiliary motors, comm adapters | Keep at least one spare; document slot addresses; plan swap steps |

| Tier 3 | Nuisance failure during low staffing | Sensor cables, relays, terminal blocks, SD cards | Bundle by machine; label with location; store with ESD protection |

An overlooked driver of downtime sits below the PLC entirely: the control network. In my field work, a surprising portion of “PLC down” calls originate from failing managed switches, fiber SFPs, or serial‑Ethernet gateways. Because these devices fall outside many parts lists, they rarely have spares on‑site. If this pattern is unfamiliar at your plant, review switch logs for port flaps and errors, and consider adding one spare switch and a pair of the most common media converters to your Tier 2 plan.

Lead Times and Supply Chain Reality

Not all delays are mechanical. Industrial Automation Co. reports extended lead times on select Siemens, Yaskawa, and ABB items due to tariff rerouting and shipping constraints, with many parts taking two to eight weeks if not already on a shelf. Those delays become more punishing as output ramps up ahead of the holidays and maintenance labor thins out. By contrast, OEM and distributor “quick ship” programs, such as those presented by Emerson, can reduce waiting drastically when the requested SKU exists in a regional warehouse. The difference is less a contradiction than a matter of definition and scope: quick‑ship programs cover subsets of families and regions, while global shortages affect other SKUs at the same moment.

One practical nuance that often catches teams off guard is shipping compliance for batteries preinstalled in CPUs or HMIs. Air shipments of coin cells or lithium packs can trigger hazmat handling and add a day even when stock exists nearby. If time is tight and the product allows it, ask the supplier to ship without the battery installed or to declare the battery properly so routing is predictable. The gain from fast fulfillment evaporates if the package sits for reclassification at a hub.

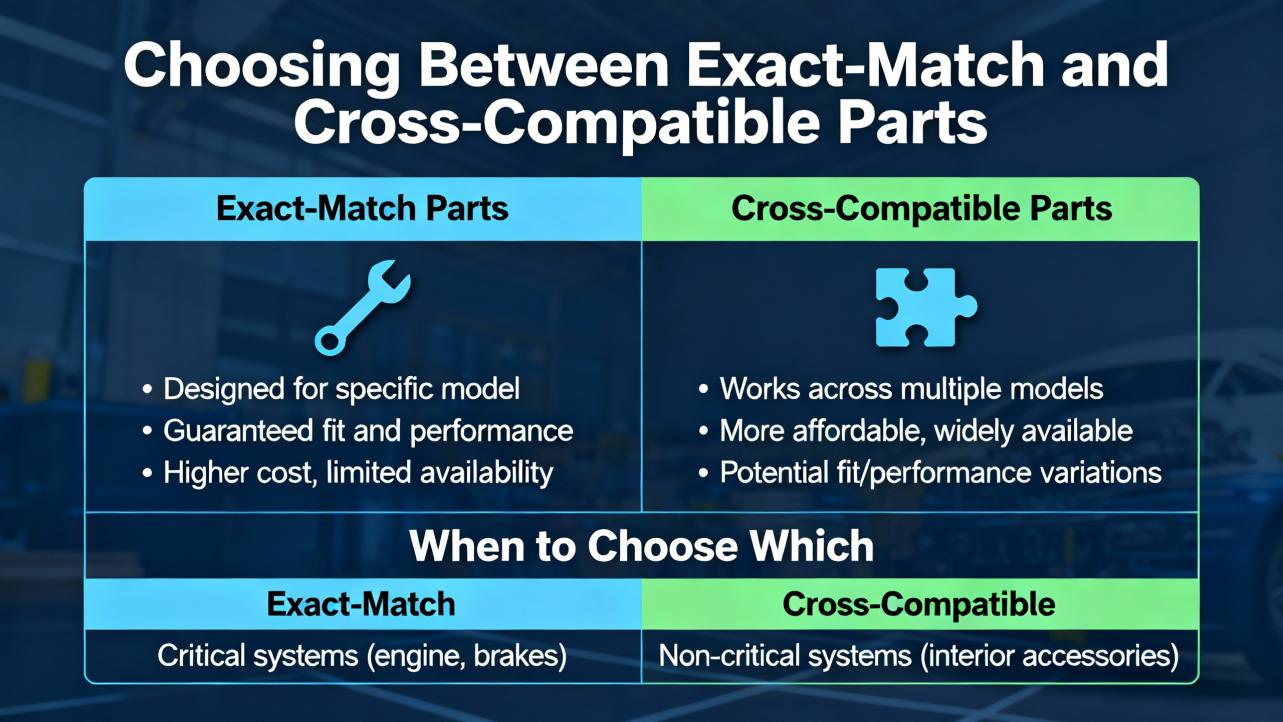

Choosing Between Exact‑Match and Cross‑Compatible Parts

When the exact part cannot arrive before the next shift, a tested alternative can end a costly outage. Industrial Automation Co. points to cross‑compatible replacements as a way to save 30–50% and to arrive days sooner, especially around legacy families such as Allen‑Bradley SLC 500 modules or PowerFlex drives. The trade‑off is that compatibility must be verified at both the hardware and the firmware levels, and application adjustments may be required.

| Option | Advantages | Trade‑offs | When it makes sense |

|---|---|---|---|

| OEM exact‑match | Minimal revalidation; known fit | Longer lead, higher cost | Regulated processes, validated batches, safety‑critical |

| Cross‑compatible tested alternative | Faster availability; potential 30–50% savings (Industrial Automation Co.) | Requires validation; minor wiring or parameter changes | Legacy lines, budget pressure, moderate risk tolerance |

| Refurbished identical unit | Same form/fit; often in stock | Quality varies by vendor; confirm warranty | Obsolete parts, stop‑gap while new part is ordered |

A frequently overlooked risk is firmware or revision mismatch. Even with an exact hardware model, a different major firmware can break compatibility with your program, drive tools, or safety profile. R.L. Consulting, Inc. stresses routine backups and version control; the same discipline applies at the moment of purchase. Ask the supplier for the major firmware on the shelf, check it against your backups, and, if needed, request that they flash the unit to your revision before shipping. If uncertain, bench‑test the spare against your last known‑good backup before moving it into the cabinet.

What to Send in an Urgent RFQ

Clear details accelerate picking, programming, and shipment. Every minute saved at the quoting desk tends to convert into minutes back on the line. These are the fields that consistently shorten the cycle from request to delivery.

| RFQ field | Why it matters |

|---|---|

| Complete part number and series | Avoids near‑matches that differ by comms or I/O count |

| Firmware or revision target | Ensures program compatibility or pre‑flashing |

| Machine and slot location | Guides labeling, spares staging, and remote support |

| Required accessories | Adds needed HIM, braking resistor, key, or adapter |

| Last known‑good backup availability | Enables pre‑load or vendor validation |

| Shipping constraints and receiving hours | Aligns delivery with staffed windows and dock rules |

| Acceptance criteria | Defines pass/fail: boots, links, IO scans, or full program load |

In parallel, send the most recent configuration or program backup if you want it loaded prior to shipment. Some suppliers will bench‑test with your file to reduce risk. That small step is often the difference between a part that lands ready to wire and a part that consumes your first hour on site.

Maintenance Habits That Make Emergency Deliveries Work

Emergency spares are not a substitute for maintenance; they are an amplifier of good maintenance. R.L. Consulting, Inc. organizes PLC system care around proactive inspections, verified backups, and environmental control. That approach turns fast delivery into fast recovery because the replacement is installed into a stable ecosystem, not a failing one. Schedule routine inspections monthly or quarterly to tighten connections and verify power quality, perform annual deep dives that include I/O testing and sensor calibration, and run documented checks after production changes, power events, or firmware updates. Keep backups with version control, and make sure as‑built drawings and network topologies are current enough that a night‑shift technician can navigate them.

Standards are your ally during a crisis because they make code and wiring predictable to any competent technician. These references guide both your day‑to‑day work and your emergency swaps.

| Standard | Focus | Emergency value |

|---|---|---|

| IEC 61131‑3 | PLC programming languages and structures | Easier code review, faster logic validation |

| NFPA 79 | Electrical safety of industrial machinery | Safer swap procedures, compliant wiring |

| ISA/IEC 62443 | Industrial cybersecurity | Controlled remote access during recovery |

| UL 508A | Control panel design | Predictable panel layouts, safer service |

| IEEE guidance | Power quality and grounding | Stable supplies prevent repeat failures |

Program and Safety Considerations During Emergencies

A rushed replacement can solve one problem and create another if the PLC program does not handle degraded conditions gracefully. The core question is simple: when communication, control, feedback, or power is lost, what does the system do next? LinkedIn’s engineering guidance emphasizes defining these emergency scenarios up front and identifying critical process parameters such as pressure, temperature, flow, level, and speed that must be monitored and kept within safe bands. That thinking belongs not only in design, but also in how you stage spares. If the replacement drive ships with defaults that alter ramp times or fault behavior, you may inadvertently change safe‑state responses. A good habit is to maintain a “golden parameter set” for each drive and HMI, store it alongside your PLC backups, and validate it in a bench test or a low‑risk cell before pushing it to the production line.

Sourcing Channels for Fast Parts

When every hour counts, source selection is strategic. OEM quick‑ship programs, global distributors, stocking specialists, and local integrators each create different paths to a box on your dock. Emerson’s QuickShip illustrates the OEM route, leveraging a worldwide footprint and regional stocking. Distributors combine broad brand coverage with logistics discipline. Stocking specialists such as Industrial Automation Co. focus on breadth across legacy and current lines, including refurbished options that can resurrect discontinued hardware. Local integrators do something different: they carry a small, highly specific inventory that mirrors the plants they serve and can hand‑deliver.

| Channel | Strengths | Watch‑outs |

|---|---|---|

| OEM quick‑ship | Direct fit, global logistics, current models | Program limits by SKU and region |

| Broadline distributor | Multi‑brand reach, predictable handling | Inventory varies by branch and season |

| Stocking specialist | Depth in legacy, new and refurbished options | Validate testing standards and warranty terms |

| Local integrator | Immediate familiarity, on‑hand niche items | Narrower inventory; depends on prior relationship |

Differences you hear between sources about what is “available” often trace to definitions and timing. One supplier may define availability as “in the region, two‑day ground,” while another means “on our shelf, overnight ready.” Ask explicitly where the item sits today and what transit mode is included.

Buying and Care Tips for Emergency Spares

The goal is not to own a warehouse; it is to be ready for the failure that will actually occur. Start by labeling each spare with the machine name, slot address, and target firmware where applicable. Store electronics in antistatic packaging with silica gel, and keep them in a climate‑controlled cabinet rather than a dusty maintenance locker. Rotate batteries in memory‑backed devices on a schedule so the spare you grab at midnight is not already depleted. For drives, stage common accessories—HIM modules, braking resistors, or pre‑terminated harnesses—so a missing cable does not strand a good drive.

Two practical details deserve attention. First, avoid immediate power‑up of a part that just arrived from a cold truck; condensation on a chilled board can cause a nuisance fault or worse. Allow the part to reach room temperature before applying power. Second, treat network spares like PLC spares. A managed switch with a saved configuration and a pre‑documented port map turns a network fault from a forensic exercise into a five‑minute swap.

Pros, Cons, and Risk Framing

The single strongest argument for an on‑hand Tier 1 spare is not theory; it is math you can feel during a holiday rush. A single hour of line downtime often exceeds the cost delta between a refurbished spare and an overnighted new part. That does not mean buying every option. It means matching spare strategies to line impact, maintaining clean backups so firmware and parameters are not a surprise, and choosing vendors whose test procedures and warranties you trust. Industrial Automation Co. notes that cross‑compatible parts can save 30–50% and arrive faster, a compelling lever when the line is not under a quality regime that mandates exact models. If product validation or safety certification ties you to a specific part and revision, push earlier into OEM quick‑ship channels, request pre‑flashing, and arrange a bench validation by the vendor or your integrator before the part leaves the dock.

Seasonal Reality: Fall and Year‑End

As temperatures drop and output climbs in the ramp to year‑end deadlines, unplanned downtime compounds. Industrial Automation Co. flags that waiting until November is too late to begin a parts plan. That matches what integrators and maintenance leads experience across sectors: holiday schedules reduce staff redundancy while shipping lanes get crowded. Build your tiered list early in the fall, check lead times on the SKUs that burned you last year, and fill the obvious gaps. You do not need every spare; you need the right ones.

Takeaway

Emergency PLC parts delivery is a capability you build before the siren sounds. It starts with a tiered understanding of your failure points, extends through precise RFQs and disciplined backups, and leans on sourcing partners who can actually put a box on your dock when you need it. Emerson’s fulfillment programs demonstrate what fast can look like from an OEM; Industrial Automation Co. shows the value of cross‑compatibility and deep stock across brands; R.L. Consulting, Inc. underscores the maintenance and standards discipline that turns fast delivery into fast recovery. If you add one habit this week, make it this: capture firmware and parameter baselines for your Tier 1 assets, store them with your backups, and verify the versions on any spare you buy. That single step removes the most common cause of “it powered up, but the line still won’t run.”

FAQ

How fast can I realistically get a PLC CPU or VFD when the line is down?

Speed hinges on stock location and how specific your request is. OEM quick‑ship programs such as those presented by Emerson can move in‑stock items quickly, while global shortages can push other SKUs to multi‑week lead times as Industrial Automation Co. has observed. Specify the full part number, series, and firmware to avoid near‑matches that waste hours.

Is a cross‑compatible replacement safe for production?

It can be, provided you validate fit and function. Industrial Automation Co. reports meaningful cost and time advantages, particularly for legacy families. The practical safeguard is to check firmware, I/O maps, and parameters against your backups and to bench‑test when possible. In regulated environments, stick to exact‑match components unless your change control allows alternatives.

Should I buy refurbished parts?

Refurbished units are often the fastest route for discontinued items and can be appropriate for non‑regulated applications. Verify the vendor’s testing process, warranty terms, and the component’s revision. When in doubt, request photos of the tested unit’s diagnostics or a simple power‑on video to confirm basic health before shipment.

What program changes should I prepare for emergency swaps?

Define safe states for loss of communication, control, feedback, or power, and identify which parameters—pressure, temperature, flow, level, and speed—must stay bounded under those conditions, as highlighted in LinkedIn’s guidance. Store golden parameter sets for drives and HMIs and make sure your PLC backups include comments and version notes so you can validate behavior after a swap.

Which standards matter most when recovering from a failure?

For faster, safer recoveries, keep your work aligned to IEC 61131‑3 for readable, maintainable PLC code, NFPA 79 for safe control wiring, ISA/IEC 62443 for secure remote access during emergencies, and UL 508A for panel construction. R.L. Consulting, Inc. emphasizes that adherence simplifies audits and keeps systems consistent when multiple technicians touch them under pressure.

References

- https://www.academia.edu/115764687/ANALYSIS_OF_FACTORS_AFFECTING_SUPPLY_CHAIN_MANAGEMENT_EFFICIENCYE_THE_CASE_STUDY_ON_ETHIOPIAN_CONSTRUCTION_WORKS_CORPORATION

- http://dspace.mit.edu/bitstream/handle/1721.1/38579/156345024-MIT.pdf?sequence=2&isAllowed=y

- https://www.plctalk.net/forums/threads/how-do-you-recommend-spare-parts-to-customers.119270/

- https://www.empoweredautomation.com/beginner-s-guide-to-automation-plc-what-you-need-to-know

- https://supplychain-mechanic.com/?p=433

- https://automationforum.co/how-to-increase-plc-speed-7-optimization-tips-advanced-programming-guide/

- https://resources.pcb.cadence.com/blog/handling-and-shipping-electronics

- https://dipslab.com/plc-safety/

- https://www.embedded.com/essential-practices-for-safely-shipping-sensitive-electronics/

- https://industrialautomationco.com/collections/plc-parts?srsltid=AfmBOoqfEQymz2MKg_QDTvWOfs_gFFdwIr1Pl9CmO2uLhiy5tA2w1qvr

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment