-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Discontinued Siemens PLC Modules: Finding Legacy System Replacements

As a systems integrator who has kept legacy lines running through every kind of parts shortage and platform sunset, I’ll start with the hard truth. Siemens PLC modules reach end of life, and the pain shows up in production first: creeping downtime, unpredictable lead times, and rising exposure when one aging module has no easy replacement. Fortunately, there is a repeatable way to identify official successors, select practical stopgaps, and plan modernization without taking a critical line offline. This guide distills what works on real projects and aligns it with current guidance from Siemens and reputable industry sources.

What “Legacy” Means in Practice

In the field, “legacy” does not automatically mean unreliable. It means a controller or module whose lifecycle and support posture no longer align with business risks and production goals. Legacy PLCs typically exhibit limited processing headroom, poor integration with modern systems, increasing cybersecurity exposure, shrinking availability of spare parts, and a dwindling pool of experts who can troubleshoot them efficiently. These are the exact characteristics highlighted by modernization guidance from Balaji Switchgears, and they mirror what many plants feel long before an OEM declares a product obsolete.

Two terms matter when planning the path forward. Your installed base is the full inventory of PLC assets and configurations you have in service. Your cutover is the switch from the current to the new system in production. Contec IAS emphasizes mapping the installed base early and designing the cutover with testing and rollback in mind. Those steps are the difference between a low-drama weekend changeover and a week of emergency work.

The Official Path: Finding Siemens Successor Modules

When a Siemens module is discontinued, start with Siemens Industry Online Support or SiePortal. Enter the module’s article number, open the product page, and review the lifecycle panel. The key is the Successor product tab. Siemens’ own FAQ walks through a CPU 1516‑3 PN/DP example where the original article number leads to a designated successor article; the page links directly to that successor module. If the successor module’s page does not show a Successor product tab, it is considered current.

The practical value of the official path is compatibility and speed. A compatible successor typically drops in without project changes, and Siemens notes you can reuse the existing SIMATIC memory card. After replacement, diagnostic tools may show an informational mismatch between the installed (online) and configured (offline) module; this is expected under spare-part compatibility and does not block operation. One caution matters: Siemens only guarantees 100% compatibility from a module to its immediate successor. If a successor has also been discontinued, repeat the lookup and follow the chain, paying close attention to the compatibility notes along the way.

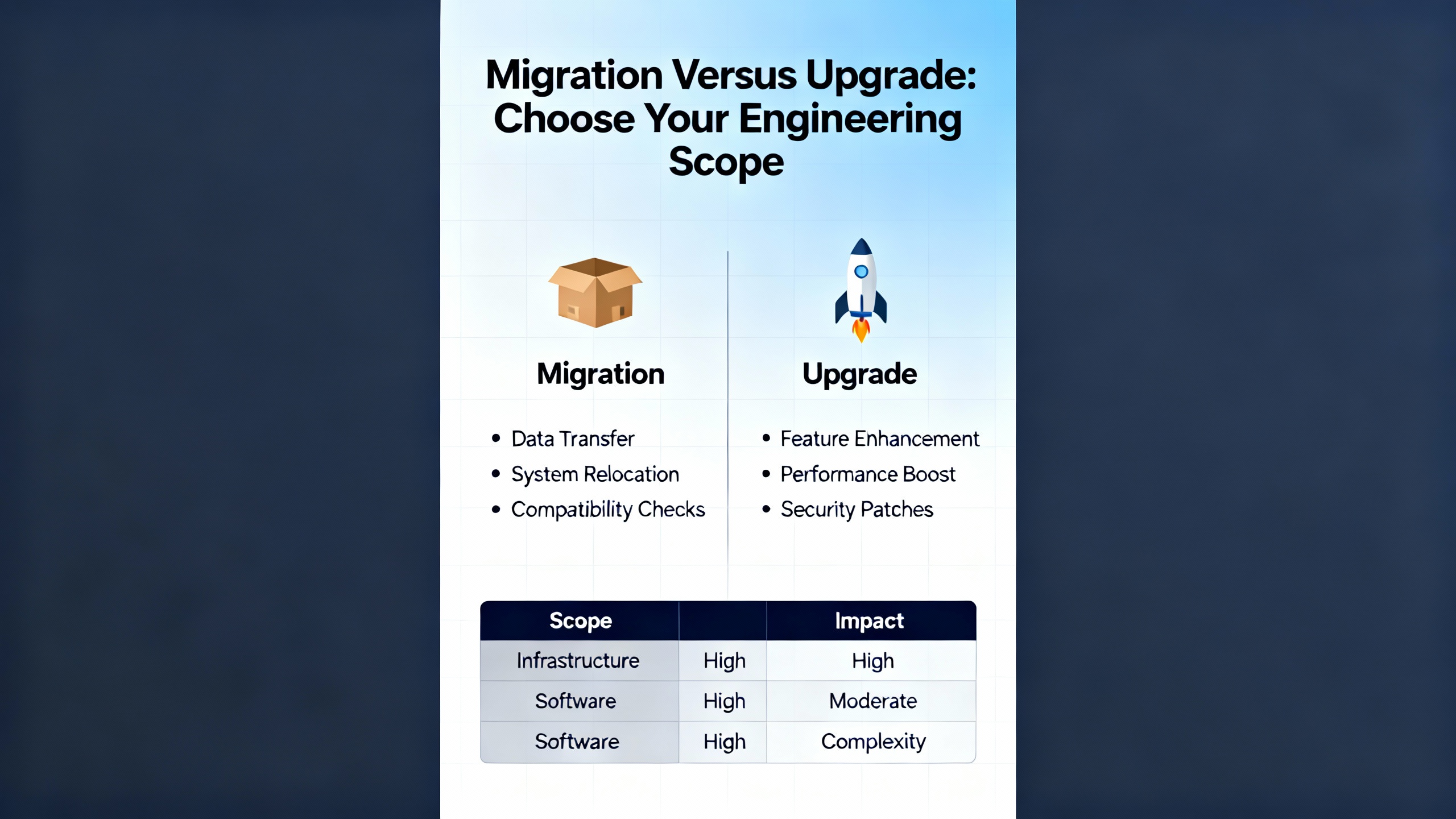

Migration Versus Upgrade: Choose Your Engineering Scope

There are two main ways to replace discontinued hardware: migration and upgrade. EZSoft Inc. draws the line clearly. Migration ports the existing control behavior onto newer hardware, using conversion tools and adapter cards to replicate wiring and keep logic largely intact. Upgrades move you to a modern platform and rewrite code and I/O end to end to unlock new features and performance.

Here is a concise comparison you can use to choose the right path for each asset.

| Path | What it does | Pros | Cons | Downtime profile |

|---|---|---|---|---|

| Migration | Converts existing logic and maps I/O to new hardware; retains behavior | Lower cost to start, faster execution, minimal changes to infrastructure | Imperfect 1:1 mapping risks runtime issues; tools are not always seamless | Shortest, better suited to tight windows |

| Upgrade | Rewrites code, reworks wiring for a newer platform | Access to latest features, performance, safety improvements, lower long-term obsolescence risk | Higher upfront cost, longer downtime, operator retraining | Longer, best scheduled with staged windows |

If your plant can live with the current logic and needs a safe bridge through obsolescence, migration is often the right move. If cyber-risk, diagnostics, analytics, and future scalability are business priorities, then a planned upgrade delivers more value over time. EZSoft’s advice is to decide proactively, not after a failure. That echoes what we see in the field.

Modernization Strategies That Work on the Floor

Balaji Switchgears outlines four modernization strategies that align neatly with real plant constraints. A direct replacement keeps program architecture intact and swaps in compatible hardware, which reduces change risk and cost but does not expose new features. A phased approach modernizes in stages to maintain production, particularly effective on larger systems with diverse I/O families. A comprehensive overhaul resets the platform for maximized scalability and future readiness, which demands more budget and schedule control. A hybrid approach mixes new and old components to control risk while progressively modernizing.

On large systems, Contec IAS recommends replacing obsolete electronics first while retaining existing wiring via adapter solutions. That tactic buys breathing room for logic cleanup later. Stabilize initially by running the original software with the vendor’s migration tools before you update logic in a second phase. Across all strategies, the people risk matters as much as the technical risk. Set conservative cutover windows and design a rollback that can be executed quickly by the shift on duty.

Planning to Minimize Downtime

Plants rarely get the luxury of lengthy outages. The work sequence that least disrupts production starts with a thorough inventory of the installed base. Flag obsolete model numbers, unsupported components, critical nodes, and high-risk processes. Clarify scope early so teams can rally around a one-time swap or a multi-site program. Choose a platform with long-term support, open standards, and alignment with your SCADA and MES stack.

Adapter-based swaps, off-line testing, and staged logic deployment are your strongest levers to cut downtime. Validate mappings, edge cases, and operator workflows in a staging rack or simulation environment well before cutover. When the line is complex or safety-critical, deploy updates in steps with a rollback plan that has actually been tested, not only documented. Contec IAS consistently places testing and rollback at the center of cutover planning, and that philosophy pays for itself.

The 2025 Reality: Repair or Replace

Industrial Automation Co. frames the current repair-versus-replace decision with numbers that match what plants feel every day. Unplanned downtime can cost about $5,600 per minute on critical lines. Tariffs and supply instability have pushed prices on some foreign-made parts by roughly 30% to 145%, and OEM lead times around 10 to 16 weeks are still common. These conditions penalize wait-and-see strategies.

Repairs make sense when the part is not mission-critical, the failure is isolated, and you have a repair partner that performs full functional tests under load using OEM-grade parts, then backs the work with a warranty, which quality shops commonly set in the 6 to 24 month range. A replacement is the right call when failures recur, the downtime meter is running, the OEM has ended support, or you need modern protocols or diagnostics today. A good rule of thumb is to compare the repair quote to the cost of a surplus or successor unit; if the repair approaches half the cost of a replacement, it is time to think long term.

| Decision factor | Repair bias | Replace bias |

|---|---|---|

| Criticality and downtime accumulation | Non-critical asset, quick test/repair turnaround | Mission-critical line, mounting downtime |

| Failure profile | Isolated component fault | Recurring failures or multiple modules failing |

| Economics | Repair costs well below replacement, meaningful remaining life | Repair exceeds about half of replacement cost |

| Lifecycle and support | OEM support still present, parts available | OEM obsolescence declared, support ended |

| Capability needs | No modern features required | Need diagnostics, remote access, or modern protocols |

A final cost lesson from Control Engineering and Lafayette Engineering is worth underscoring. Plants running decade-old installations and outdated operating systems on HMIs tend to face greater cyber risk and longer emergency projects when failures finally force action. A reactive replacement will almost always cost more than a planned upgrade; one case study pegged the premium at roughly double. Proactive audits and 12 to 24 month roadmaps keep you out of that corner.

Sourcing Discontinued Siemens Modules Safely

When you must buy legacy parts, treat sourcing as a quality process. Industrial Electrical Warehouse warns that counterfeits and misrepresented refurbished items are a real risk and that form, fit, and function equivalents do not always drop in. Use manufacturer cross-reference guides and search part-number variants to expand your options. Lean on specialized suppliers for authenticity checks, model cross-references, and expedited shipping. Decommissioning events, auctions, and liquidations can be useful channels, but always confirm provenance and condition.

If the exact module is gone, consider retrofit paths such as adapter plates or harnesses that let modern components meet your compliance and performance needs. Third‑party repair and refurbishment are often worthwhile for boards, contactors, and relays while you stage a broader migration. Above all, implement obsolescence management: maintain a live registry of critical assets, track production status, and pre‑source critical spares. Industrial Automation Co. also recommends stocking pre-tested backups on site to cut mean time to repair. That single practice erases hours from outage timelines.

| Source channel | What to verify | Risk to manage | Mitigation |

|---|---|---|---|

| Specialized obsolete-parts suppliers | Authenticity, test records, warranty terms, revision match | Counterfeits or misrepresented condition | Require functional test under load and documented warranty |

| Surplus from decommissioning/auctions | Provenance, storage conditions, hours of use | Unknown history and hidden faults | Insist on inspection reports and acceptance tests |

| Manufacturer cross-references | Form/fit/function equivalence, protocol support | Subtle incompatibilities or wiring changes | Pilot on a noncritical cell before plantwide adoption |

| Third‑party repair | Component quality, load testing, turnaround, warranty | Incomplete fix or early failure | Choose partners offering 6–24 month warranties and OEM-grade parts |

Third-Party Equivalents and Form‑Fit‑Function Options

Some vendors publish Siemens‑compatible modules as drop‑in replacements for families such as S7‑200 and S7‑300. Unimat Automation positions its products as matching dimensions, electrical interfaces, and bus connections while running Siemens projects without logic changes. They also cite options aligned to S7‑1200 and 200 SMART environments, and they highlight warranty offerings and sample programs.

Treat these claims as you would any critical component decision. Validate in a pilot cell against your exact firmware and I/O mix. Confirm that diagnostic behavior, safety functions where present, and network integration meet your site standards. Audit the vendor’s documentation, driver support, and long‑term support posture. If you go this route, document clear acceptance criteria and retain a quick rollback path. Vendor alternatives can be part of a resilient strategy, especially when OEM spares are scarce or subject to long lead times, but they should not bypass engineering diligence.

Cybersecurity and Platform Obsolescence

HMI and engineering workstations fall out of support as surely as PLC modules do. Control Engineering cautions that running Windows 7 or older means you no longer receive security patches after January 14, 2020. That single constraint often forces an HMI update and creates an opportunity to tighten PLC lifecycle risk at the same time. Lafayette Engineering notes that most modern PLC systems standardize on Ethernet, which simplifies integration and support. Combine OS upgrades with network segmentation, patch baselines, and secure remote access capability so your modernization yields measurable reductions in cyber risk.

The age heuristic matters here. Systems older than about ten years usually trail significantly in diagnostics, performance, and maintainability, even if they are still running. Resist the temptation to treat age alone as a disqualifier, but also avoid assuming “still running” equals “low risk.” A planned, phased refresh of code structures, tag hygiene, and HMI workflows pays back in maintenance hours saved and errors avoided.

Buying Tips and Aftercare That Reduce Risk

In our projects, the most successful replacements start simple and stay disciplined. Always begin with the article number to locate the official successor and read the compatibility notes. When you need a discontinued part, insist on functional test reports under load and a written warranty with clear terms. For repairs, the best partners use OEM‑grade components or equivalents and can return a fully tested unit quickly with a warranty window that reflects confidence, commonly measured in months rather than weeks. For replacements, weigh the cost of the long outage you may avoid against the price tag in front of you.

Keep pre-tested spares on site for the modules that would stop production if they failed. Build and maintain a staging rack or simulation environment where you can validate logic changes and replacement hardware off line. After a CPU replacement with a Siemens successor, reuse the memory card when allowed to minimize change risk, and be prepared for an informational diagnostic mismatch. Document a rollback plan the crew on shift can execute without a senior engineer on the phone at 3:00 AM. Finally, train operators and maintenance techs as part of the change; even small differences in diagnostics and alarm workflows can add minutes when it matters most.

A Simple Decision Map for Legacy Siemens Modules

When you have an official successor and your control behavior is stable, the fastest, lowest-risk step is to replace the module with its Siemens‑designated successor and reuse the memory card. If you cannot source a successor quickly because of long lead times or cost, consider a repaired or surplus unit from a vetted supplier, backed by documented testing and a meaningful warranty, while you plan the next phase. If production needs and cybersecurity goals have outgrown the platform, prioritize an upgrade and phase it to protect uptime. Where form‑fit‑function alternatives exist and you choose to evaluate them, run a controlled pilot and keep a tested rollback path. Across all cases, anchor your plan in a current installed‑base inventory and a cutover strategy that includes off‑line testing and operator dry runs.

Takeaway

Discontinuations are inevitable, but disruption is optional. Start with Siemens’ official successor route to preserve behavior with minimal engineering. Decide early between migrating what you have and upgrading to what you need; both can be correct depending on risk, downtime tolerance, and long‑term goals. Treat sourcing as a quality function, use testing and warranties to manage risk, and keep pre‑tested backups on hand. Above all, plan proactively. The cost of waiting for a forced outage is measured not only in dollars per minute but also in the stress placed on your teams and processes.

FAQ

What is the quickest way to find a replacement for a discontinued Siemens module? Use Siemens Industry Online Support or SiePortal, search by the module’s article number, and open the product page. The Successor product tab lists the officially designated replacement. If that tab is absent for the successor, the module is current. This process is outlined in Siemens’ own FAQ.

Will I need to change my project if I install an official successor? Siemens indicates that swapping a CPU for a compatible successor typically does not require project changes or a project upgrade, and the existing SIMATIC memory card can be reused. Expect a diagnostic message noting the online/offline mismatch; it is informational and does not block operation under spare‑part compatibility.

How do I decide between repairing a legacy module and replacing it? Consider downtime risk, recurrence of failures, cost, and lifecycle status. Industrial Automation Co. notes that unplanned downtime can run about $5,600 per minute on critical lines, tariffs have inflated some parts costs significantly, and lead times often span 10 to 16 weeks. If repair costs approach half a replacement and failures recur, replacement generally wins.

Can I use a third‑party form‑fit‑function module instead of Siemens? Some vendors market Siemens‑compatible modules, including drop‑in replacements for S7‑200 and S7‑300 families. Treat these as vendor claims and validate them in a pilot. Confirm electrical compatibility, firmware behavior, diagnostics, safety functions where applicable, and long‑term support. Keep a tested rollback plan.

What is the best way to minimize downtime during modernization? Map the installed base, define scope, choose a platform with long‑term support, and test off line before cutover. Contec IAS emphasizes adapter‑based hardware swaps to retain wiring and phased logic updates with a fast rollback path. Stabilize first by running the original software, then refine logic in a later window.

Is running old HMIs or engineering stations risky even if the PLC is stable? Yes. Control Engineering and Lafayette Engineering highlight that running Windows 7 or older means no security patches after January 14, 2020, which increases cyber risk. Consider coordinating HMI and PLC lifecycle actions so your network and operator stations meet current security expectations.

References

| Publisher |

|---|

| Siemens Industry Online Support |

| Siemens SiePortal |

| Balaji Switchgears |

| Contec IAS |

| EZSoft Inc. |

| Industrial Automation Co. |

| Industrial Electrical Warehouse |

| Control Engineering |

| Lafayette Engineering |

| Unimat Automation |

- https://www.plctalk.net/forums/threads/alternative-plc-compilers-for-siemens-s7-plcs.113768/

- https://sourceforge.net/software/product/SIMATIC-STEP-7/alternatives

- https://balajiswitchgears.com/upgrading-plc-systems-strategies-for-modernization/

- https://contec-ias.com/plc-upgrade-checklist-plan-without-downtime/

- https://www.controleng.com/three-signs-it-might-be-time-to-upgrade-a-plc/

- https://ezsoft-inc.com/difference-between-plc-migration-and-upgrading/

- https://www.lafayette-engineering.com/if-you-are-experiencing-these-signs-its-time-to-upgrade-your-plc-system/

- https://maplesystems.com/siemens-hmi-alternative/?srsltid=AfmBOoqm50LB3xQbCmIopgiFvjXV7KUERBYkX9w2hgAvLq-ow4jMAPkc

- https://plcautomationgroup.com/blog/obsolete-but-not-out-of-reach

- https://theautomationblog.com/siemens-vs-allen-bradley-plcs-one-engineers-perspective/

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment