-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Honeywell TDC 2000 Obsolete Components: Vintage DCS Parts Provider

Keeping a Honeywell TDC 2000 installation healthy in 2025 is equal parts discipline and detective work. As a veteran systems integrator and a pragmatic project partner, I approach these legacy fleets with two goals that rarely conflict: protect today’s uptime and preserve tomorrow’s options. That means sourcing the right obsolete components, validating how they behave in your racks and addressing, and deciding when a replacement kit or a modernized platform will reduce downtime risk more than it increases change risk. This article distills field‑tested practices, vendor intelligence, addressing details, and buying criteria sourced from respected communities and suppliers, including Honeywell Process Solutions, Control.com forum contributors, and established specialist vendors. It is written to help reliability engineers, maintenance leads, and operations leaders who must keep a TDC 2000 plant dependable without losing the thread on modernization.

What the TDC 2000 installed base looks like today

Even though new development has moved to Honeywell’s newer platforms, there remains a significant installed base of TDC 2000 systems. Multiple specialist providers position their services around this need, offering surplus, recycled, refurbished, and some new‑old‑stock modules for controllers, I/O, and communication interfaces. Vendors highlight support for legacy Honeywell distributed control systems, emphasizing the availability of genuine parts and expert assistance to extend lifecycle and maintain process reliability for aging installations. Providers such as Neptune Controls and DcsSupplier publicly focus on TDC 2000 and related families, while Topbrands PLC and other distributors present broader catalogs where buyers request quotes rather than see published prices. The common thread is simple: the market still demands fit‑for‑service replacements that let plants defer disruptive redesign while they schedule structured upgrades.

Honeywell has made clear that modernization pathways exist for TDC/TPS systems. Honeywell Process Solutions notes that upgrade approaches can retain intellectual property and operator familiarity by preserving assets like graphics, control strategies, controllers, I/O processors, wiring, and native displays. The qualitative benefits cited include efficiency gains and lower maintenance costs. Industry peers such as Marathon Petroleum and Chevron Oronite are referenced as having modernized, providing useful social proof for plant leaders who must defend both risk and value propositions internally. Meanwhile, sources such as Petrospare reiterate that official migration routes to Experion PKS are available and emphasize performance and security improvements over legacy baselines. In practice, most facilities take a staged route: stabilize the existing TDC 2000, stock critical spares, and then phase modernize without discarding valuable prior engineering work.

Core hardware families you still encounter

When you service Honeywell TDC 2000, you commonly encounter two hardware domains in your inventory and on the benches of reputable recyclers: Advanced Multifunction Controller components and Process Interface Unit and related boards.

Advanced Multifunction Controller (AMC)

AMC modules and their base units form the heart of many control and I/O configurations in legacy TDC 2000 environments. Field‑facing suppliers list base and control units such as J‑MBU01, J‑MBU11, J‑MBU20, and J‑MSC10, together with communication pieces like the J‑MHM10 Hi‑Way interface. Typical I/O coverage includes analog output modules such as J‑AOM10 and J‑HCX00, high‑level analog input via J‑HAM10, digital input such as J‑DIM00 at 24 V, and digital output via J‑DOM00, J‑DOM10, and J‑DOM20. Specialty AMC modules that still surface in spares catalogs include the J‑HMM00 high‑level multiplexer, J‑PIM00 pulse input, and J‑STM00 often labeled STDCM. The presence of well‑known part numbers such as 80360143‑011 under analog output lines is a reminder to verify duplicates across catalog descriptions before ordering, because some identifiers appear in more than one listing context.

Process Interface Unit (PIU/CCFA) and related boards

On the PIU side, vendors describe families of processor and regulator boards, A/D converter boards, Data Hiway interface modules, I/O multiplexors, I/O bus controllers, PROM and RAM boards, and MUX drivers. Literature from parts specialists lists board‑format model strings such as 4DP7APXAD111, 4DP7APXAD211, and 4DP7APXAD911 for A/D, 4DP7APXDH111, 4DP7APXDH222, and 4DP7APXDH233 for Data Hiway, and 4DP7APXIO111 and 4DP7APXIO211 for I/O multiplexor and bus controller, alongside PROM/RAM identifiers like 4DP7APXPM133, 4DP7APXPM144, 4DP7APXPM155, and 4DP7APXPM233. Processor and regulator board numbers such as 30731832‑001, 30731832‑005, 30731832‑501, and 30731808‑001 also remain visible on the secondary market. Data Hiway Interface Board 51400700‑100 and Data Hiway I/O Board 51108088‑100 are highlighted explicitly by suppliers, underscoring how the communication layer is often the bottleneck in restoration work when faults are intermittent or rack‑localized.

Backplanes and rack terminal packs

RTP‑style modules and enhanced variants—listed by vendors as J‑RTP00, J‑RTP10, J‑RTP20, J‑RTP30, J‑RTP50, and J‑RTP80, together with J‑ETP00 for enhanced digital output—show how plant‑floor wiring and backplane form factors remain highly relevant. In a mixed installed base, that mechanical and electrical fit is often decisive; plants aim for form, fit, and function replacements to avoid rewiring and requalification of field circuits.

Slot addressing and logical mapping that still bites newcomers

The best time to resolve addressing is before you start moving modules, not after a cabinet door close. Experienced engineers lean on the TDC help content included with Quick Builder for Experion and on shared field knowledge. Contributors on the Control.com forum have summarized a key rule: I/O slots are shifted to start at logical slot 17, a convention that separates them from modulating slots 1 through 16. Understanding that offset prevents surprise when logical references point beyond the physical positions you might first expect.

A typical mapping, as discussed in those practitioner notes, shows analog input and output channels occupying the lower pairs of the logical range, while digital I/O and multiplexers step through higher ranges with specific subslot schemes. Redundant controller configurations spread across two racks with primary and redundant sides, where the primary AI, AO, DI, and DO map to the 21–32 logical bands and corresponding redundant positions often remain spare. Even small mistakes—such as transposing 25–26 with 29–30 on high‑density digital inputs—compound during commissioning. Use the Quick Builder TDC help file to confirm module‑to‑slot addressing and subslot ranges on your site and validate primary‑redundant assignments against the actual drawing sets.

Typical module mapping at a glance

The following snapshot reflects addressing patterns commonly cited by practitioners and vendors. Always validate against your actual racks and the Quick Builder help content before making changes.

| Module | Typical logical slots (Experion) | Subslots/channels | Notes |

|---|---|---|---|

| HAM10 Analog Input | 17–18 | Inputs 1–16 | AI cards placed at the start of the shifted range |

| AOM10 Analog Output | 19–20 | Outputs 1–16 | AO follows AI in the shifted pattern |

| HMM00 Analog Multiplexer | 23–24 | Subslots 1–8 | Multiplexed analog positions |

| DIM00 Digital Input | 25–26 and 29–30 | Commonly subslots 1–8 or 1–16 | DI density varies by subslot scheme |

| DOM00 Digital Output | 21–22, 27–28, 31–32 | Subslots 1–8 each | 16‑channel DO cards in multiple bands |

Channel counts often cited in field notes include 16‑channel analog input, 16‑channel analog output, 32‑channel digital input, and 16‑channel digital output. Subslot numbering frequently runs 1 to 8 or 1 to 16, depending on the card type. Where redundant controllers are split across racks, typical spare mappings exist, but your site documentation remains authoritative.

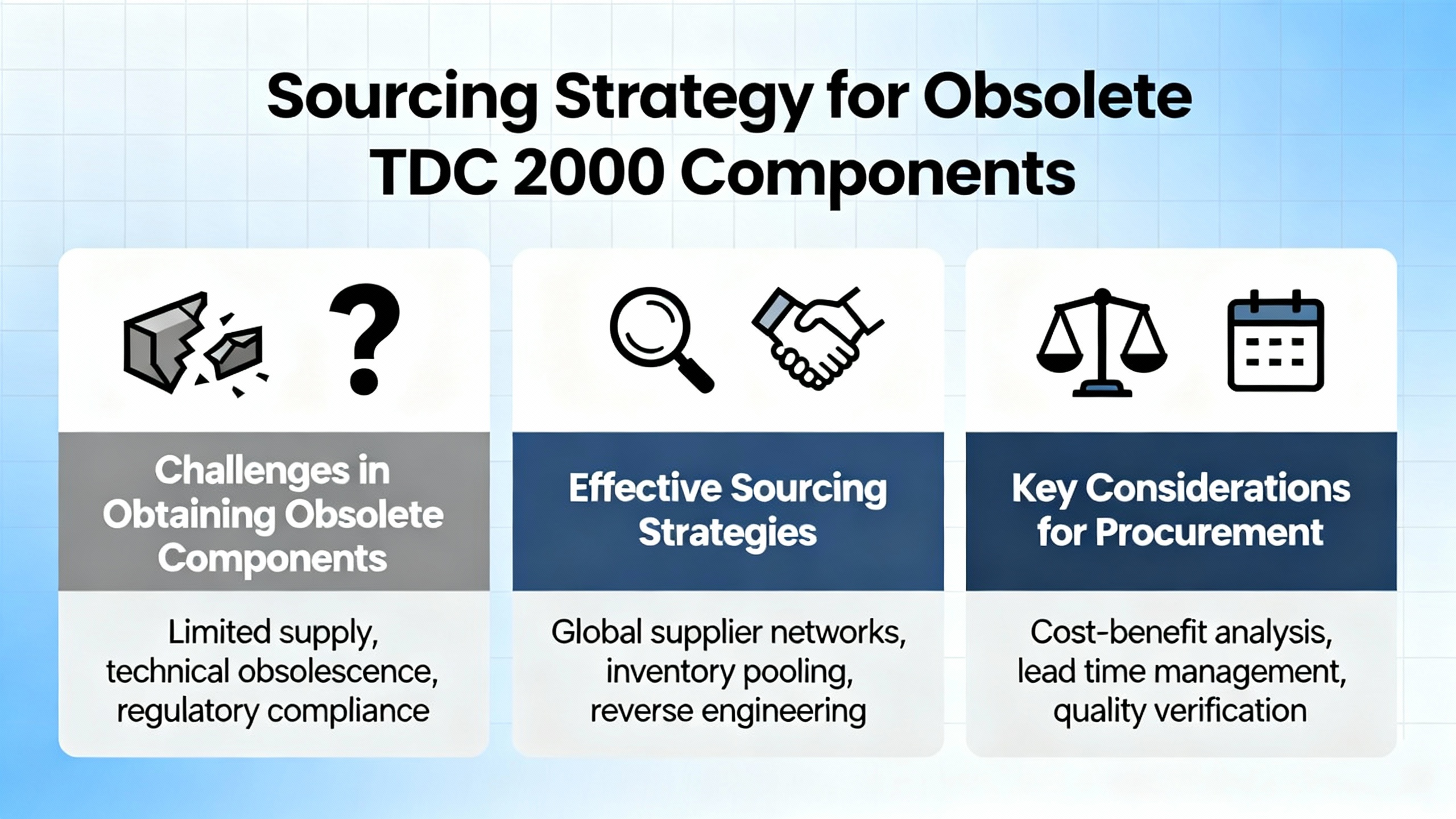

Sourcing strategy for obsolete TDC 2000 components

The TDC 2000 parts market spans specialized recyclers, surplus stockists, and marketplaces. In our experience, the best results come from matching the sourcing path to the criticality of the loop and the time you have to qualify a board.

Where the market is

Suppliers such as Neptune Controls position themselves around surplus, recycled, and new Honeywell parts, emphasizing hard‑to‑find legacy components and inviting requirement lists for quick quotations. DcsSupplier organizes catalog collections for Honeywell TDC 2000 systems with claims of genuine controllers, I/O modules, and replacements supported by expert technical help and fast global shipping. Other distributors, including Topbrands PLC, offer Honeywell TDC collections where the workflow is request‑for‑quote rather than cart checkout, which aligns with the reality that condition, test status, and firmware often drive pricing and availability.

Some specialist providers emphasize certified recycled parts as a distinct service. A. Hock GmbH describes testing in a Honeywell DCS environment with specially developed programs and a complete test sequence within 24 hours. Their coverage includes power‑up checks and self‑tests, structured hardware verification using a Hardware Verification Test System, and system software exercises to confirm operation under system conditions. The program claims continuous improvement and leverages decades of experience, and it spans Honeywell lines TDC 2000, TDC 3000, MFC, APM, and HPM Controller. When you are buying recycled parts to protect uptime, these are the kinds of test assurances worth paying attention to.

Secondary marketplaces can be useful for lower‑criticality spares or for building a lab stock. It is not unusual to see board‑level items offered at attractive prices. For example, recent listing snapshots show a TDC‑2000 Processor Card Assembly Board with part number 30731832‑001 offered at $21.51 and a Trend Memory Assembly board 30735974‑2 at $21.56 on a major marketplace. Prices at that level underscore why market checks are prudent, but they do not substitute for test documentation or a return policy.

What “certified” should mean

When a vendor calls a Honeywell part certified, we look for evidence that mirrors the A. Hock approach: a Honeywell DCS test environment, power‑up and self‑tests, structured hardware verification with a dedicated hardware verification system, and system software exercises. We also expect a stated turnaround for test execution, and we want a report that links the part number and serial number to the exact procedures performed. If a vendor claims certification but cannot show test scope and results, you are paying for a label rather than a lower risk profile.

On marketplace purchases

Marketplaces are valid channels for some use cases, especially for building or replenishing a noncritical bench stock. Before buying, ask the seller for the exact part number and revision, confirm whether the board was functionally tested, and request photos of the part in a powered test or an associated test report. If the listing is under $25.00 for a board that would otherwise be a chokepoint in your control strategy, the opportunity might be real or it might be a quick‑turn flip. You can reduce risk by planning to bench‑test those items in a controlled setup before field use.

Secondary‑market snapshots

| Item description | Part number | Observed price | Source type |

|---|---|---|---|

| Processor Card Assembly Board | 30731832‑001 | $21.51 | Marketplace listing |

| Trend Memory Assembly | 30735974‑2 | $21.56 | Marketplace listing |

These snapshots highlight price signals only and do not imply test status. Use them to calibrate value and then decide if additional cost for verified, documented testing is justified by your risk tolerance.

Repair, replace, or modernize

Operations leaders typically face three choices round‑the‑clock: repair failed modules, replace them with compatible modules or kits, or modernize in stages. There is no single right answer across plants, but the considerations are consistent.

Replacement kits that keep you running

When the requirement is to restore function quickly without modifying the system architecture, replacement kits aimed at TDC 2000 I/O can be an effective lever. The Honeywell TDC 2000 Universal Controller Input/Output Replacement Kit with part number 51196886‑200 is presented by a specialist distributor as a comprehensive kit designed to replace outdated or malfunctioning I/O modules. The kit’s positioning emphasizes seamless integration with existing TDC 2000 environments, high‑quality construction for durability and longevity, and straightforward installation intended to minimize downtime. In practice, we treat kits like this as a way to standardize a fix and reduce diagnosis time in the field. Before purchase, confirm the exact part number, match the kit’s content against your installed I/O types, and schedule installation during a maintenance window.

Modernizing without throwing away IP

Honeywell’s modernization guidance for TDC/TPS systems underscores a principle many operators value: preserve intellectual property and past engineering investment while extending longevity. Modernization approaches are described as retaining graphics, control strategies, controllers, I/O processors, wiring, logic configurations, and native displays, helping operators stay familiar with the plant while stepping forward on efficiency and security. Peer examples are referenced to show feasibility. Separate commentary about migration to Experion PKS points to improved features and stronger security relative to legacy platforms, and it frames migration as an official, supported pathway rather than a bespoke leap. That distinction matters when you are pitching a phased capital plan to leadership.

A pragmatic decision framework

The practical approach compares the cost and risk of repeated repairs against the certainty of modernization. If you are replacing the same module family repeatedly and cannot secure tested spares, it may be time to pivot part of that annual spend toward a targeted modernization step that preserves your IP. If your fault profile stems from environmental or wiring stress rather than the module itself, investing in higher‑assurance recycled parts backed by structured test documentation may solve the right problem. Many plants do both: carry certified recycled spares to protect uptime and develop a staged modernization plan to reduce maintenance drag over the next budget cycles.

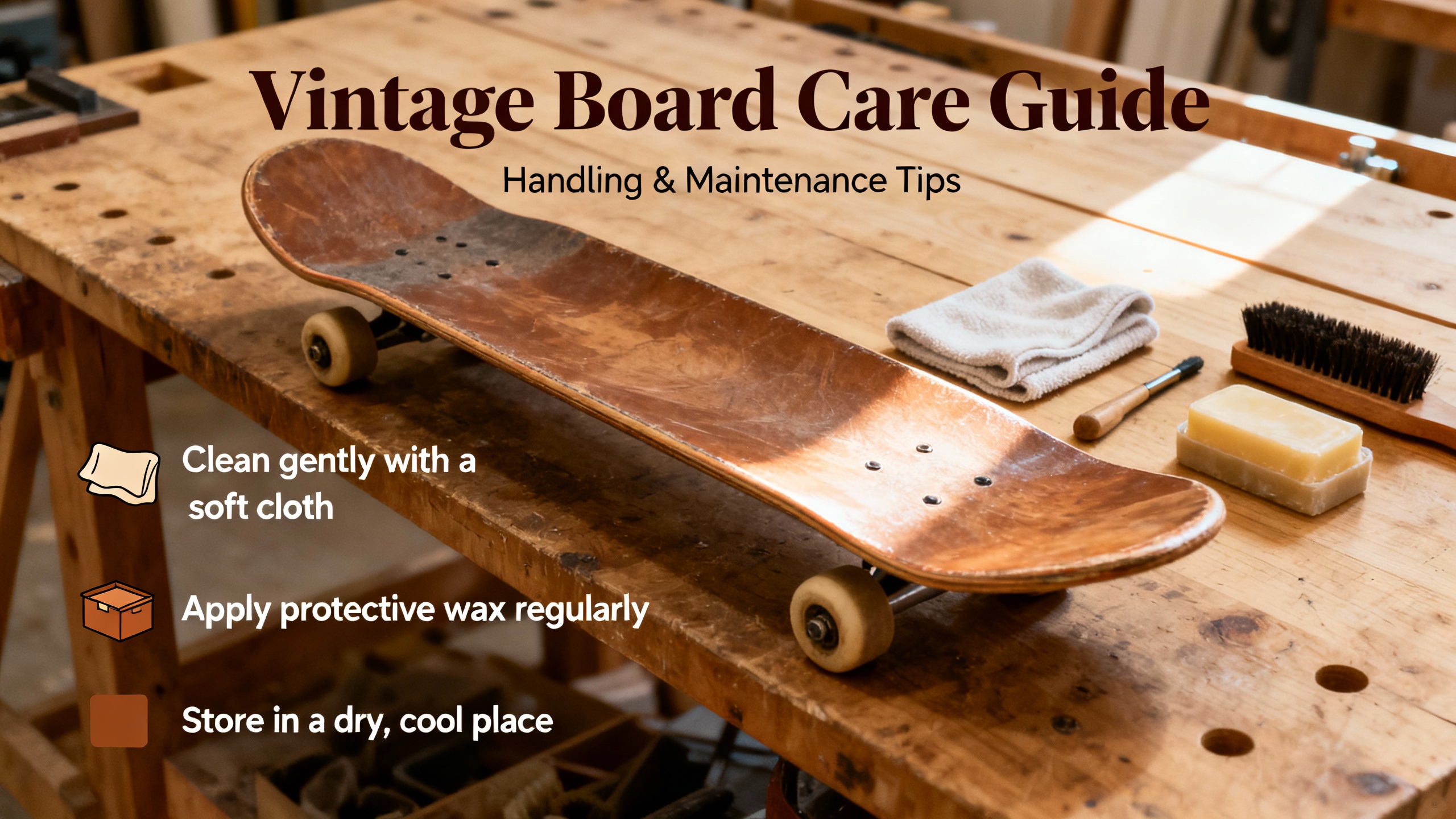

Handling and care for vintage boards

We favor a simple principle for legacy Honeywell boards: treat them like the scarce assets they are. Reputable recyclers demonstrate test coverage in a Honeywell DCS environment and complete power‑up, self‑tests, hardware verification, and software tests within a stated turnaround. That kind of rigor both validates a purchase and gives maintenance teams confidence in change‑of‑state behavior once a board hits a rack.

At the plant level, put acceptance testing on rails. Every inbound part should be paired with a test ticket that records part and serial numbers, the vendor’s test documentation reference, and your own powered‑bench result in a safe environment before cabinet installation. Where possible, align your local bench exercise to echo the vendor’s claimed procedures, so anomalies can be diagnosed using the same language. Finally, implement a documented handling routine that moves boards from receipt to sealed storage to pre‑install bench to field install with minimal ESD exposure and logging at each step. It is administrative, but when the part count is small and the process is visible, it works.

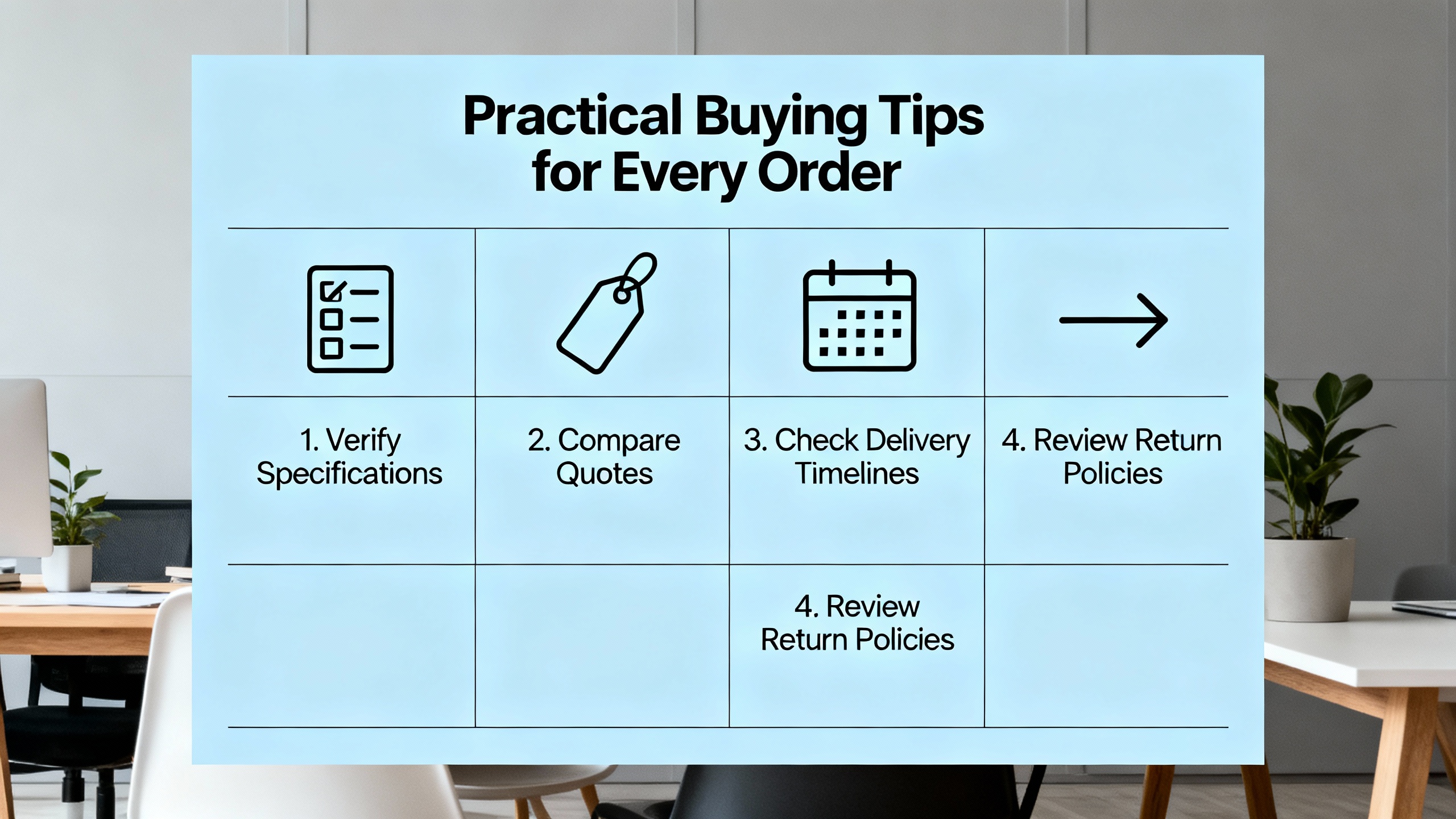

Practical buying tips we follow on every TDC 2000 order

Successful procurement for obsolete Honeywell hardware starts with specificity. Provide both the model and the exact part number every time, and include any known hardware and firmware revisions. Confirm whether you are dealing with TDC 2000 versus TDC 3000 or TPS and whether Data Hiway or other interfaces are involved, because mixing families without verification creates compatibility risk. Align replacements with the right backplane and slot conventions, particularly around the logical slot 17 offset rule and subslot schemes for high‑density digital inputs and outputs. Ask vendors for functional test results and describe the testing method; when a seller uses a Honeywell DCS test environment with a defined hardware verification system and can complete a test sequence quickly, that is a meaningful differentiator. Verify warranty terms, return windows, and whether DOA replacement is a defined policy rather than ad hoc. Request clear photos, including part labels, to validate the revision and to log your incoming lot. Plan installations during maintenance windows, and keep at least a minimum on‑hand quantity for high‑criticality loops so you are never one failure away from an unplanned shutdown.

Quick reference tables

The following tables summarize component families that recur in TDC 2000 work and show addressing cues commonly cited by practitioners. Use them as prompts, not as substitutes for site documentation and Quick Builder help content.

| Family | Example identifiers | Function | Sourcing notes |

|---|---|---|---|

| Advanced Multifunction Controller (AMC) base/control | J‑MBU01, J‑MBU11, J‑MBU20, J‑MSC10 | Base units and control module | Verify base type matches I/O mix and rack plan |

| Hi‑Way interface | J‑MHM10 | Data Hiway communication | Match to site Data Hiway architecture |

| Analog output | J‑AOM10, J‑HCX00, 80360143‑011 | AO module | Confirm channel count and revision |

| High‑level analog input | J‑HAM10 | HLAI module | Validate mapping to logical 17–18 when applicable |

| Digital input | J‑DIM00 (24 V) | DI module | Confirm subslot and density scheme |

| Digital output | J‑DOM00, J‑DOM10, J‑DOM20 | DO module | Map to logical 21–22, 27–28, 31–32 where applicable |

| Multiplexer and specialty | J‑HMM00, J‑PIM00, J‑STM00 | HLMUX, pulse input, STDCM | Check function fit for loop specifics |

| Backplane and enhanced DO | J‑RTP00/10/20/30/50/80, J‑ETP00 | RTP family and enhanced DO | Confirm form/fit with existing RTP |

| Data Hiway boards | 51400700‑100, 51108088‑100 | Interface and I/O boards | Communication layer often limits restoration |

| PIU and related | 4DP7APXAD111/211/911, 4DP7APXDH111/222/233, 4DP7APXIO111/211, 4DP7APXPM133/144/155/233 | A/D, Data Hiway, I/O, PROM/RAM | Use exact identifiers; request test documentation |

| Processor/regulator boards | 30731832‑001/‑005/‑501, 30731808‑001 | Processor and regulator | Bench‑test before field install |

FAQ

Q: Is it still viable to keep a TDC 2000 running with spares rather than migrate immediately?

A: Yes, many plants maintain reliable operation with a disciplined spares strategy and reputable recycled or surplus parts providers. Vendors focused on TDC 2000 support this approach, and certified recycled parts tested in a Honeywell DCS environment provide additional assurance. At the same time, modernization paths exist that preserve intellectual property, so it is wise to plan phased upgrades even while you keep today’s system stable.

Q: What is the practical meaning of logical slot 17 in TDC addressing?

A: Control practitioners describe a shifted addressing model where I/O slots begin at logical slot 17, separating them from modulating slots 1 through 16. Typical mappings place analog inputs at 17–18, analog outputs at 19–20, multiplexers at 23–24, and digital I/O across 21–22, 25–26, 27–28, 29–30, and 31–32 with subslot conventions. Always confirm with the Quick Builder TDC help content and your site drawings before making changes.

Q: How should I qualify “certified recycled” Honeywell parts?

A: Ask for evidence that mirrors established practices: test execution in a Honeywell DCS environment, power‑up and self‑tests, structured hardware verification using a dedicated hardware verification system, and system software tests. Expect a documented turnaround and a report tied to your part and serial number. If a supplier cannot produce this, treat the certification claim cautiously.

Q: Can I assume interchangeability between TDC 2000 and TDC 3000 modules?

A: Do not assume interchangeability. Vendors explicitly advise verifying part numbers, hardware and firmware revisions, and backplane or slot compatibility before ordering. This is especially important across families and network layers, where form‑fit differences and signaling define boundaries that cannot be crossed without redesign.

Q: Are marketplace bargains worth the risk for critical loops?

A: Marketplace listings can be cost‑effective for building bench stock or addressing noncritical needs. Observed prices around $21.50 for certain boards show how inexpensive some items can be. For critical loops, prioritize parts accompanied by structured test results and return policies from suppliers who stand behind their work, because the cost of a mismatch or early failure usually exceeds any headline savings.

Q: When should I pivot from repeated repairs to modernization?

A: When failures cluster in the same families and you cannot secure tested spares, or when downtime exposure rises, consider shifting spend toward an incremental modernization step that protects your intellectual property and preserves operator familiarity. Honeywell’s modernization guidance and peer examples reinforce that you can extend longevity without discarding prior engineering investments.

Takeaway

A dependable TDC 2000 strategy blends disciplined sourcing, precise addressing, and a phased view of the future. On the sourcing side, pair exact part numbers and revisions with suppliers that prove their testing in a Honeywell DCS environment, and bench‑test locally before installing. In configuration, respect the logical slot 17 rule and confirm module‑to‑subslot ranges with the Quick Builder help content and your site documentation. At the portfolio level, keep certified recycled spares for near‑term resilience and pursue modernization paths that retain intellectual property and operator familiarity. This pragmatic blend reduces downtime risk today while building a credible bridge to tomorrow.

References

Control.com forum

Honeywell Process Solutions

Neptune Controls

DcsSupplier Limited

Industrial Automation Co.

A. Hock GmbH

Parts4Automation

Petrospare

Topbrands PLC

eBay marketplace

- https://www.neptunecontrols.com/

- https://www.nseauto.com/honeywell-tdc2000-series-30732254-001_p10959.html

- http://www.parts4automation.com/display-325.html

- https://dcscenter.com/pdfs/honeywell-tdc2000.pdf

- https://www.dcssupplier.com/collections/honeywell-tdc2000-series?page=2&srsltid=AfmBOooj3A-wzkAN2g1ijzb_zed7ItGhPgtJqjG2pgheimRq9LfOkcT4

- https://www.ebay.com/itm/165611241634

- https://industrialautomationco.com/products/honeywell-tdc-2000-universal-controller-input-output-replacement-kit-51196886-200?srsltid=AfmBOop2RwLr24a_oq-NfBn4h3nZhPj7Qsi4M2qB7wLU2RTNBRL8D9N2

- https://www.petrospare.com/collections/honeywell-tdc-2000-3000-series

- https://www.topbrandsplc.com/collections/honeywell-tdc-2000-tdc-3000-ucn-series

- https://westernprocess.com/tdc-2000-parts/

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment