-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Same Day ABB DCS Components: Express ABB Distributed Control Parts

Keeping a continuous process plant running is as much about preparation as it is about response. When a controller module dies at 2:00 AM and the line is bleeding dollars by the minute, you face a tight choice: source the exact ABB DCS component the same day or watch schedule, quality, and compliance risk unravel. I have spent years integrating, upgrading, and rescuing ABB System 800xA and Symphony Plus sites in energy, chemicals, pulp and paper, and metals. This article distills what actually works when you need same‑day ABB DCS parts without compromising safety or long‑term maintainability. It also explains when fast fulfillment is the right move, how to vet parts under pressure, and how to build a spares strategy so midnight scrambles fade into exceptions rather than norms.

What “Same Day” Really Means in DCS Operations

Same day is less about a shipping label and more about risk containment. In practice it means validating that a replacement module or assembly is compatible, authentic, tested, and ready to go on the first attempt, then moving it from a known shelf to your rack before the outage burns through a shift. The logistics window is tight, but the technical diligence cannot be waived. Industry reporting has put unplanned downtime for process assets at roughly tens of thousands of dollars per hour, and in many plants that figure can exceed $50,000 per hour when you include safety, product quality, and compliance exposure. In those moments, the premium on immediate availability is rational. The key is to couple urgency with disciplined checks so the “fix” does not become a second, more expensive fault.

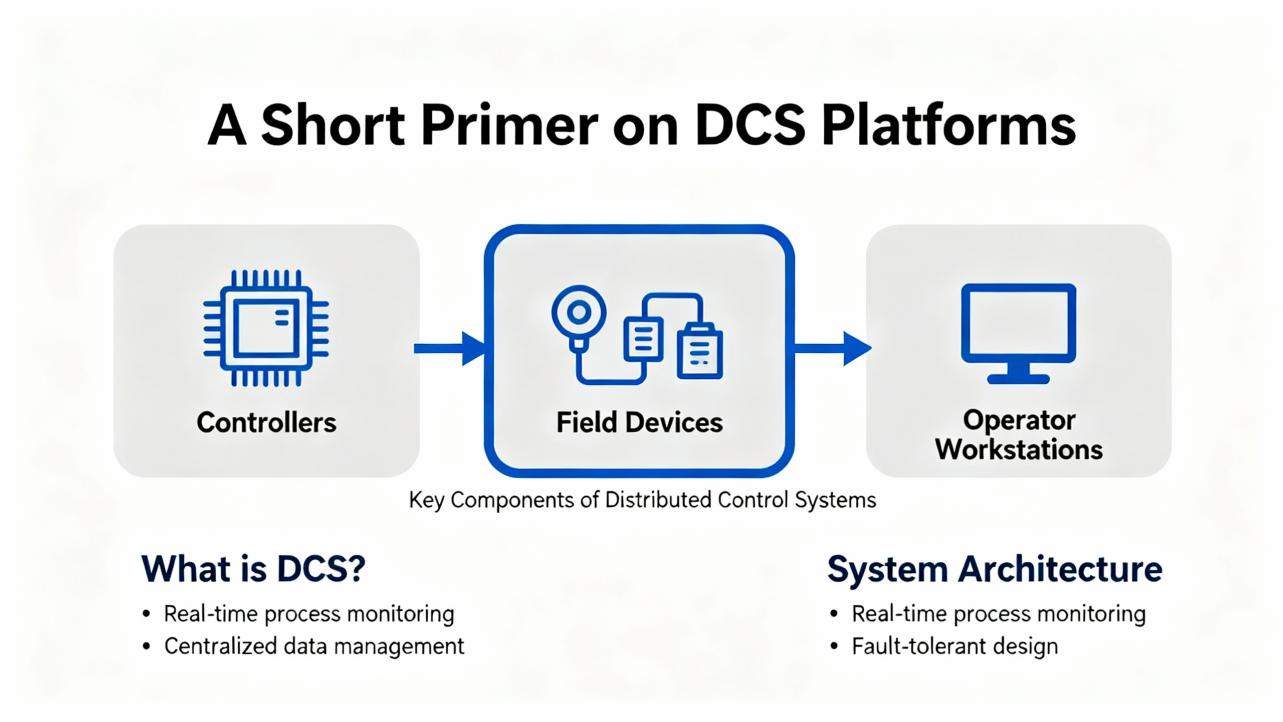

A Short Primer on ABB DCS Platforms

Distributed Control Systems coordinate plant equipment through networked controllers and remote I/O while operators supervise and adjust from consoles. ABB’s two flagship platforms are System 800xA and Symphony Plus. System 800xA brings extended automation by unifying process, power, safety, and information on a single operations and engineering environment, with broad controller support and connectivity into hundreds of devices and networks. Independent market analysis reported by Informed Infrastructure and ARC Advisory Group has repeatedly cited ABB as the global DCS market leader for more than two decades, with a market share lead reflected in continuous investment and service reach. That matters when you are sourcing parts at speed, because the combination of installed base, partner channels, and lifecycle services greatly influences the odds of finding a correct component quickly.

When Same‑Day Components Are the Smart Move

The best use case for express parts is a hard failure or intermittent fault on a single module in a functioning architecture where the rest of the system is healthy and the spare pool is empty or out of revision. Typical triggers are power supply degradation, a communications interface failure on a controller or I/O head, or a spontaneous reboot traceable to age and thermal stress. Where the plant’s batch or continuous process can be stabilized on bypass or redundant capacity, the narrowest viable repair is often replacing the exact module with a compatible revision.

There are also scenarios where same‑day is a strategic risk reduction. If your redundant partner module is already running on mismatched firmware or a legacy backplane, letting the system ride another day raises the chance of a second fault that forces an extended outage. In these cases, an immediate like‑for‑like replacement reduces compound risk, provided the new unit is verified for hardware and firmware compatibility.

The Hidden Risks of Rushing

Acting fast does not mean cutting corners. Counterfeit or mismatched modules can introduce electrical faults, firmware handshake failures, or intermittent overdrawing on the backplane that only show up under load. Industry reporting has documented seven‑figure production losses and early “new old stock” failures when unverified parts were installed, with warranties voided when traceability was missing. You avoid these outcomes by insisting on verifiable provenance, by matching not just model numbers but voltage and current specs, protocol roles, and controller firmware interoperability, and by bench‑testing outside the process first.

Where to Source in a Hurry without Regret

Large ABB installed bases have multiple sourcing lanes on the clock: specialized automation parts vendors, OEM legacy programs and authorized refurbishers, reputable marketplaces, and asset recovery channels. Each path can work if you apply the right controls.

| Fulfillment Path | Advantages | Risks | Warranty/Assurance | Best Use Case |

|---|---|---|---|---|

| Specialized industrial parts vendors with test labs | Functional testing, traceable serials, photos, certificates of conformity, documented firmware | Price premium; inventory claims must be verified | Often offers documented test reports and meaningful DOA windows | Critical modules needing high confidence and rapid dispatch |

| OEM legacy channels and authorized refurbishers | Platform expertise, compatibility guidance, limited‑run or requalified stock | Lead times for factory routing; sometimes limited quantities | OEM paperwork and standard terms | High‑criticality replacements where alignment with ABB specs is paramount |

| Professional marketplaces and auctions | Broad selection, competitive pricing | Variable test depth; counterfeit risk; shipping relays | Listing warranties vary; vet seller reputation | Non‑critical spares or interim units while OEM path proceeds |

| Asset recovery and decommissioning sources | Cost advantage, chance to bulk‑secure matching sets | Unknown storage history; environmental wear | Buyer must arrange testing; limited or no warranty | Building reserve stock after thorough requalification |

Sourcing notes in the table reflect widely reported market practices and my field experience; lead times and warranties vary by supplier and stock location. Confidence is high that the controls and trade‑offs shown are material to fast, reliable outcomes.

Compatibility and Quality Checks You Should Never Skip

Replacements in ABB DCS environments require more than a part code match. You must confirm electrical and firmware parameters and that the module’s role aligns with the controller and network context. Voltage ranges for I/O should align within a tight tolerance of the original spec, current draw must stay within backplane capacity, and protocol support and role mode must match what the controller expects. Firmware parity is especially important in redundant pairs and controller clusters; mixing incompatible revisions introduces failover anomalies and drift in diagnostics. You should also verify that any redundancy enablers, high‑integrity options, or safety certifications on the original unit are present in the replacement so that risk assessments and safety cases remain valid. These checks are routine in well‑run maintenance teams and are supported by ABB lifecycle documentation and service practices.

| Compatibility Check | Why It Matters in a Rush |

|---|---|

| I/O voltage and current within backplane limits | Prevents latent brownouts and thermal faults once load rises |

| Protocol and role matching on comm modules | Avoids silent master/slave misconfigurations and fieldbus errors |

| Controller and module firmware interoperability | Ensures redundancy stays bumpless and diagnostics remain true |

| Safety and high‑integrity options parity | Maintains SIL claims and plant safety posture |

| Physical fit, keying, and backplane revision | Prevents mechanical mismatch and connector strain |

The controls above are standard due diligence in ABB System 800xA and Symphony Plus estates. Confidence is high that applying them reduces rework and secondary downtime.

Pre‑Install Testing Under Pressure

When the clock is running, bench‑testing in an isolated rack can feel like a luxury. In practice it is the fastest way to a first‑time‑right install. A minimal bench test confirms power‑up behavior, LED diagnostics, communications handshakes, and analog calibration before the part ever touches the production backplane. Technicians should record firmware versions and device IDs and retain calibration records. In my experience, spending twenty minutes in a staging area prevents hours of instrument hunts and network tracing after a hurried install on a live unit.

| Test Step | Purpose |

|---|---|

| Power up on a spare rack or test jig | Verify boot sequence and basic health without risking production |

| Check LED diagnostics and error registers | Catch latent faults or revision mismatches early |

| Verify comms read/write on intended protocol | Ensure master/slave or client/server roles negotiate correctly |

| Measure I/O voltages and analog calibration | Confirm signal integrity; calibration drift around a tenth of a percent can matter in tight loops |

| Record firmware and serial identifiers | Keep redundancy and asset records consistent for future work |

These steps reflect common ABB service practices and widely documented maintenance disciplines. Confidence is high in their effectiveness for reducing MTTR under emergency conditions.

Logistics Decide Whether “Same Day” Really Happens

The difference between “ships today” and “arrives today” often comes down to basic verification. Always confirm the actual inventory location rather than accepting an intermediary’s promise to forward stock from a third site three to five days away. Ask for a packing photo that shows ESD protection and impact‑safe cushioning so vibration does not ruin a sensitive assembly in transit. Clarify cutoffs for dispatch and whether specialized couriers are available for same‑day hand‑carry. Insist on a clear dead‑on‑arrival window measured in hours, not weeks, so you can escalate immediately if the module fails staging tests. These are practical details that move the needle more than big promises.

Building a Spares Strategy So Emergencies Shrink

Plants that rely on express parts every quarter are running too close to the edge. The most reliable mills and utilities pair emergency sourcing with data‑driven spare parts planning. ABB has showcased spare parts analytics in production environments to improve availability and reduce inventory cost, and real‑world maintenance teams report better visibility of critical spares and improved productivity when risks and lead times are quantified and reviewed. The practical playbook is straightforward. Map your installed base down to module and firmware. Rank spares by criticality and lead time. Set min and max levels for parts that can halt a line. Review consumption quarterly against trends. Tie the spares plan to preventive and condition‑based maintenance so replacements happen on your schedule rather than during an incident. From a pure economics standpoint, keeping two of a critical controller card on the shelf frequently costs less than a single eight‑hour outage, and that arithmetic gets more favorable as utilization rises.

When Repeated Failures Signal It’s Time to Modernize

If the same class of cards keeps failing or if compatible firmware has become hard to source, an express part may be a stopgap rather than a solution. ABB’s modernization approach emphasizes innovation with continuity, where upgrades are phased to maintain production while moving the platform forward. In many estates you can reuse cabinets and field wiring by adopting I/O adapters and bridge modules, then introduce Select I/O or Ethernet I/O to add flexibility. Server and client layers can be virtualized and standardized on supported operating systems so patching, backups, and recovery are controlled. Some migrations can be executed online, particularly when redundancy and simulation are used to validate changes. The point is that emergency replacements and modernization are complementary. You use the replacement to stabilize now, then pull forward to a supported, serviceable version that reduces urgent orders in the first place. Confidence is high in the value of phased modernization based on ABB’s published practices and repeated field outcomes.

Costs and Trade‑Offs: New, Refurbished, or “New Old Stock”

New hardware is the simplest story but is not always the fastest path in legacy environments. Authorized refurbished units that preserve form and firmware can drop into older racks with less rework and often carry eighteen to twenty‑four month warranties from reputable labs. New equivalents may require configuration changes or bring firmware that does not pair smoothly with your redundant partner. Claims of “new old stock” sound attractive; the issue is storage history and early failure rates after long shelf time. This is where vendor traceability, test reports, and a clear DOA policy matter more than the label on the box.

Care and Handling That Protects Your Investment

People often focus on price and availability, then lose money on handling. Always discharge static and handle cards by the edges. Do not rest a module on conductive surfaces, even briefly. Check that front connectors and terminal bases are aligned before inserting, and never force a card past resistance that suggests the wrong slot or keying mismatch. After install, retighten field terminations and verify redundancy states from the operator station, then trend key loops for drift. These habits cost minutes and preserve hours.

Buying Tips You Can Use Today

The fastest way to cut through the noise is to ask for three concrete proofs before you commit: a photo of the exact serial label, a functional test report with firmware version and pass/fail notes, and confirmation of the physical stock location and dispatch time. If any one of these cannot be produced within minutes by a vendor claiming same‑day ship, your chances of disappointment rise sharply. For high‑criticality modules, treat the purchase like a maintenance work order: capture the part code with revision, the intended rack/slot and role, the dependency on partner firmware, and the fallback plan if staging reveals a mismatch. Finally, standardize payment terms that align with emergency procurement, including rapid DOA returns, so your finance process does not slow the plant.

How This Aligns with ABB Services and Digital Capabilities

Field support is not a solo sport. ABB’s lifecycle and modernization services cover preventive and corrective maintenance, obsolescence management, cybersecurity hardening, and operator effectiveness. Their remote and digital services can reduce the need for emergency on‑site interventions by catching degrading trends early and guiding corrective actions. Quality Control System transition services illustrate how structured KPI monitoring and targeted analysis accelerate problem resolution during critical transitions. These service models complement emergency part sourcing by lowering the frequency and severity of incidents and by bringing expert context to upgrade decisions. The view in this section blends ABB‑published service scopes with the practical ways I have seen customers use them; confidence is high on the benefits and moderate on how individual plants can adopt them based on staffing and budget.

Frequently Asked Questions

What if the replacement card is a newer revision than the redundant partner? Aim for firmware parity across the pair. If you must install a newer revision to restore service, run both modules through a controlled upgrade sequence at the next window so redundancy and diagnostics are aligned. This guidance reflects common ABB redundancy practices and high‑confidence field experience.

Can refurbished parts be trusted in safety‑related areas? Yes, when sourced from qualified refurbishers who provide traceability, functional test documentation, and matching safety options. Always verify that the replacement carries the same integrity classification and that your safety case remains valid. Confidence is high that certified refurb with documentation performs reliably.

How do I verify compatibility quickly during an emergency? Use the original datasheet and your asset records to cross‑check model and variant, voltage and current specs, protocol role, and controller firmware. Confirm physical keying and backplane revision. Vendors with test labs can validate on a bench in minutes and share reports. This method is widely practiced and high confidence.

Does same‑day shipping mean same‑day arrival? It depends on true stock location and courier options. Insist on confirmation of where the unit sits, how it will leave the building, and by when, and be ready to authorize specialized delivery. These logistics details are decisive and supported by common industry practice.

What is the right number of spares to hold on‑site? Base quantities on criticality and lead time. For modules that can stop production and have lead times longer than your allowable outage window, carrying at least one redundant set on‑site is often cost‑justified. Plants using spare parts analytics have reported improved availability and lower inventory costs by tuning these levels over time. Confidence is high that data‑driven spares planning outperforms rules of thumb.

When is an express part the wrong answer? If failures repeat on the same class of modules, if compatible firmware has become scarce, or if the operating system and server stack are out of support, you are better off stabilizing the plant and scheduling a phased modernization. ABB’s approach to continuous evolution with reuse of wiring and cabinets reduces risk and spreads cost. This is a high‑confidence recommendation from both vendor guidance and field projects.

Takeaway

Express ABB DCS parts are an essential tool, not a crutch. The fastest path back to production comes from pairing urgency with uncompromising verification: match specifications and firmware, demand test evidence, stage on a bench, then install once. Vendors that can provide traceability, valid warranties, and real‑time proof of inventory separate themselves when the pressure is highest. The longer‑term play is equally important. By auditing your installed base, aligning spares to risk and lead times, adopting analytics, and planning phased modernization, you will order fewer emergency parts and achieve more predictable operations. ABB’s market position, lifecycle services, and digital capabilities add confidence that even legacy estates can evolve without ripping and replacing. That is how veteran integrators deliver reliability on the day a part fails and resilience for the years that follow.

Sources

This article draws on ABB Group service and modernization materials for scope and methods, ARC Advisory Group findings reported by Informed Infrastructure for market context, practical procurement guidance reflected in Atlantic International University and American Public University System resources, incident and sourcing practices reported by Insights News Wire, and ABB case reporting on spare parts analytics in production environments. Where I have extended beyond published material, I have described field experience and offered confidence levels accordingly.

References

- https://www.aiu.edu/blog/procurement-management-a-comprehensive-guide/

- https://host.kelley.iu.edu/mabert/Recent_Pubs/POM_2011_no1.pdf

- https://pmc.ncbi.nlm.nih.gov/articles/PMC6458671/

- https://www.apu.apus.edu/area-of-study/business-and-management/resources/improving-procurement-strategy-in-supply-chain-management/

- https://dev-aspire.imgix.net/files/base/ebm/controlglobal/document/2025/08/6890f55e86dd7abaec512440-3bse079517ensystem800xadcsupgradesarticle.pdf?dl=6890f55e86dd7abaec512440-3bse079517ensystem800xadcsupgradesarticle.pdf

- https://new.abb.com/control-systems/service

- http://www.foks.com.tr/downloads/ABB-DCS-Brosuru.pdf

- https://www.linkedin.com/pulse/harnessing-data-using-information-management-abb-800xa-academy-4wimc

- https://www.multisoftvirtualacademy.com/blog/the-ultimate-training-guide-for-abb-800xa-dcs

- https://tomarok.com/abb-automation/

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment