-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

24 VDC DIN-Rail Power Supplies: Industrial-Grade Solutions That Keep Control Systems Running

Walk into almost any modern control cabinet and you will find the same backbone running everything from PLCs to safety relays: a 24 VDC rail fed by one or more DIN-rail mounted power supplies. Over the years, I have commissioned enough panels to know that a solid 24 VDC supply is the difference between a line that runs for years and a line that spends its nights under fault.

This article walks through how to think about 24 VDC DIN-rail power supplies from a systems integrator’s perspective: what “industrial grade” really means, how to size and mount them, how to handle grounding and noise, and how to keep them alive in tough environments. The guidance is grounded in established standards such as IEC 60204-1 and in vendor guidance from sources like ControlByte and Schneider Electric’s Ecostruxure documentation, combined with practical field experience.

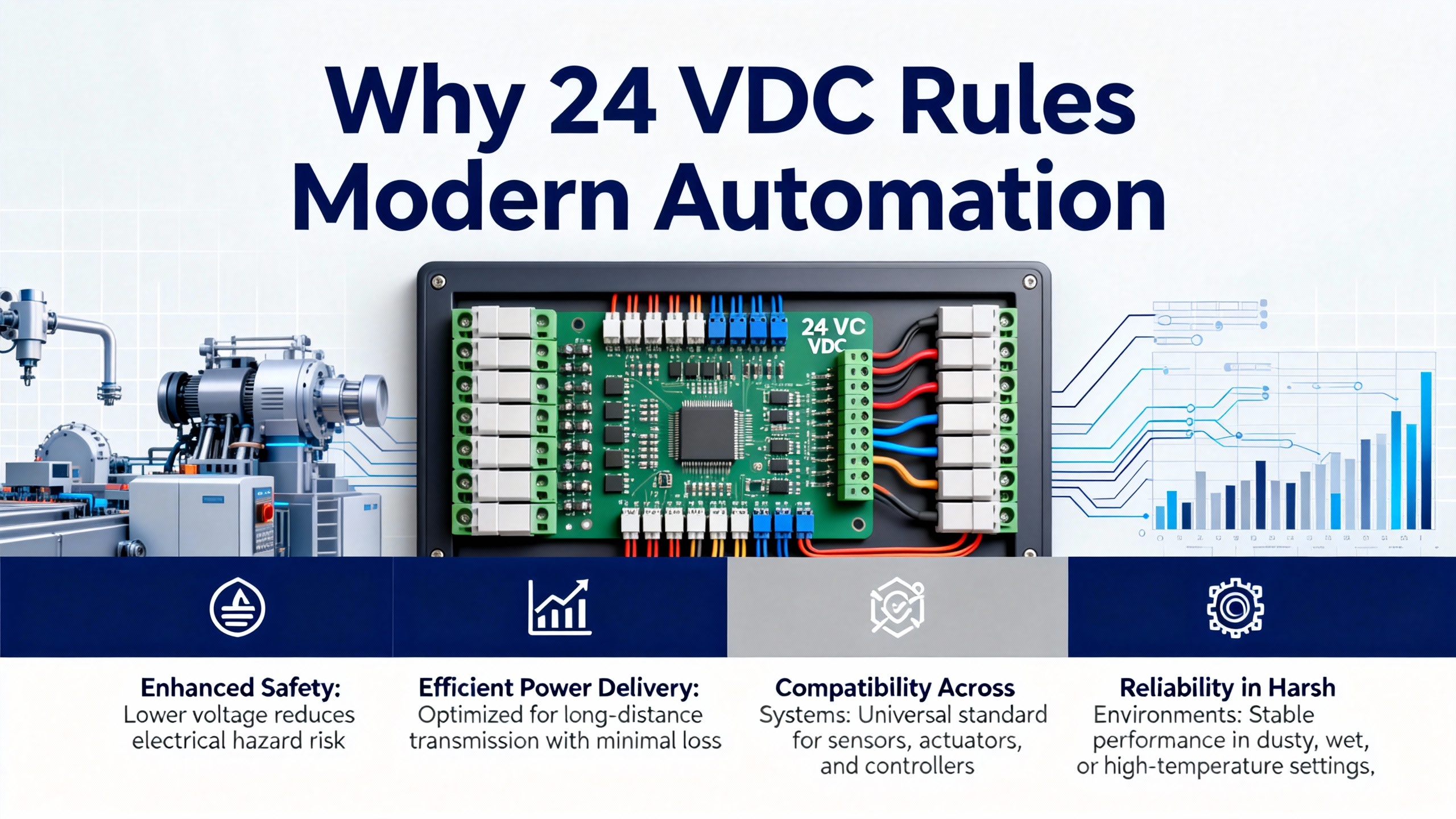

Why 24 VDC Rules Modern Automation

Twenty-four volts DC has become the de‑facto standard control voltage in industrial automation. A ControlByte analysis lays out the reasons clearly. Compared with 5 or 12 VDC, 24 VDC offers better noise immunity and supports longer cable runs, which matters when you are pulling control wiring across a machine frame or through a plant. It is also classified as a safe low voltage in the relevant standards, reducing shock risk compared with older 110 VAC or 220 VAC control circuits that were fed through control transformers.

That shift away from higher-voltage AC control circuits happened as semiconductors improved and safety expectations rose. IEC 60204-1, which governs electrical equipment of machines, pushes designers toward safer control circuits and defines how they are powered, protected, and grounded. Modern switching power supplies that turn mains AC into regulated 24 VDC fit this world far better than a simple transformer and rectifier.

On top of that, the ecosystem around 24 VDC is extremely strong. PLCs, digital and analog I/O, safety relays, photoeyes, encoders, proximity switches, HMI panels, and a long list of other devices are all available in 24 VDC variants. In practice, this means you can standardize on a single DC bus for almost everything in the cabinet and avoid the clutter and risk of multiple unrelated voltages.

What Makes a 24 VDC DIN-Rail Supply “Industrial Grade”

It helps to pin down some terms before going deeper. A 24 VDC power supply simply converts mains AC into a nominal 24‑volt DC output. Within that broad category there are a few important dimensions that separate an industrial-grade DIN-rail unit from the low-cost bricks aimed at LED strips or consumer electronics.

An industrial DIN-rail supply for automation is almost always a regulated switching supply. The CNNVVV guide on 24 V power supplies distinguishes regulated from unregulated designs and notes that regulated supplies hold the output voltage relatively constant as the load changes or the input voltage moves around. That stability is mandatory for PLCs, communication modules, and sensors. Unregulated supplies are cheaper but allow significant voltage swing and are not suited to sensitive electronics.

Industrial units implement what IEC and EN standards describe as PELV: Protective Extra-Low Voltage. As summarized by ControlByte, PELV-compliant power supplies use transformers and reinforced insulation that provide safe isolation between the mains side and the 24 VDC side. Even under fault conditions, dangerous mains voltages must not appear on the control circuit. Cheaper supplies, particularly those intended for LED lighting or IT gear, may not provide this type of separation, even if they nominally output 24 VDC.

ControlByte also points out why two 24 V 5 A supplies with similar nameplate ratings can have wildly different prices. The difference is not in the printed numbers but in safety approvals, isolation quality, robustness, and standard compliance. Industrial-grade supplies are tested and certified against standards such as IEC 60204-1, EN 50178, EN 60950-1, EN 61000-3-2, and DIN VDE 0100-410. That translates into better behavior under overload, surge, and fault conditions, which directly affects downtime and safety.

The table below summarizes the practical differences you can expect between an industrial DIN-rail power supply and a generic 24 V supply aimed at less demanding applications, based on the characteristics highlighted in the ControlByte and CNNVVV material.

| Aspect | Industrial DIN-rail 24 VDC supply | Generic 24 V LED/IT-type supply |

|---|---|---|

| Intended use | Machine control circuits, PLCs, safety, instrumentation | LED strips, IT gear, hobby projects |

| Isolation and safety | Safe isolation suitable for PELV; reinforced insulation; tested to IEC/EN | May lack PELV-grade isolation; safety approvals can be limited |

| Protection features | Overload, short-circuit, and overvoltage protection as standard | Basic overload protection; behavior in faults may be less predictable |

| Mechanical form factor | DIN-rail mounting, finger-safe terminals, cabinet-friendly dimensions | Open-frame boards or enclosed bricks with screw lugs or leads |

| Environmental suitability | Designed for control cabinets; specified derating with temperature; IP20 or better; industrial EMC performance | Often intended for benign indoor environments; limited derating information |

| Documentation and support | Detailed manuals, installation notes, and application guides | Minimal datasheet; little guidance on use in machinery |

When you are powering equipment governed by IEC 60204-1, the industrial column is where you need to be. Using a cheap supply intended for signage or consumer electronics inside a machine control cabinet is a classic false economy. You save a few dollars up front and pay for it with nuisance trips, mysterious communication issues, or, in the worst case, unsafe behavior under fault.

Sizing the 24 VDC Rail for an Automation System

The first job when specifying a 24 VDC supply is to size it correctly. Both the CNNVVV guide and the ControlByte article agree on the fundamentals: calculate the total load, then choose a supply that can deliver slightly more power than the calculated figure to improve reliability and allow for future expansion.

In practice, that means adding up the current or wattage of every device that will sit on the 24 V rail. PLC CPUs, I/O cards, safety relays, network switches, HMIs, analog transmitters, valve manifolds, and field sensors all count. ControlByte notes that common ratings for industrial 24 V supplies include 2.5 A, 5 A, 10 A, 20 A, and 40 A. In many real cabinets, you will see one supply feeding base PLC logic and I/O at a modest current, and a separate larger supply for solenoids and other more demanding loads.

The steady-state current is not the whole story. ControlByte emphasizes the importance of handling dynamic peaks. Many industrial supplies provide a short-term “boost” capability so they can ride through inrush currents or short overloads without tripping. When you are close to the rating, that boost capability can make the difference between a clean start and a cabinet full of blinking red LEDs every time a large bank of valves energizes.

The idea of consolidating supplies and using DC-DC converters to derive additional voltages appears in a technical exchange on Electronics StackExchange. The recommended approach for a system needing both 24 V and a heavy 5 V rail was to use a single 24 V external supply and derive the 5 V through a buck converter. A 5 V rail at 2.5 A represents 12.5 W of output power; with a reasonably efficient buck converter, the 24 V supply only sees about 16 W and roughly two-thirds of an amp. That kind of topology keeps mains wiring confined to one unit and lets you design a single robust 24 V backbone rather than multiple separate supplies.

In real projects, I avoid running an industrial power supply at its absolute nameplate rating. The CNNVVV guidance recommends choosing a unit that can deliver somewhat more power than the total connected load. In control cabinets, designing for something like eighty to ninety percent of nameplate under typical conditions is a pragmatic rule. It gives you room for component tolerances, ambient temperature swings, and incremental additions over the life of the machine.

Mechanical Layout and DIN-Rail Mounting Practices

DIN-rail mounting is less glamorous than current ratings, but it matters just as much for reliability and serviceability. Most industrial supplies are built around the same expectation: they will snap onto a standard DIN rail in a control cabinet, share space with breakers and contactors, and rely on the cabinet for mechanical protection.

From a layout perspective, I usually keep the 24 V supply near the incoming mains devices but clearly separated from high-heat components. The CNNVVV material underscores the need for good ventilation and notes that power supplies should not be boxed into tight spaces where heat cannot escape. In a real-world panel, that means leaving some vertical space above and below the DIN-rail supply, not stacking dense I/O modules tightly against its sides, and thinking about natural convection paths.

Schneider Electric’s Ecostruxure Building guidance for a 24 V operator display offers several practical wiring details that generalize well. It calls for copper conductors only, rated for at least about 167°F, using wire between 18 and 13 AWG for the DC feed, with the ground conductor at least as large as the power conductors. It also stresses securing power cables to the panel to avoid mechanical stress. When you put that advice into a DIN-rail context, it means routing 24 VDC wires cleanly in duct, using strain relief or cable ties near the supply, and ensuring the supply itself is firmly latched to the rail before you land any conductors.

DIN-rail supplies aimed at cabinets generally carry an IP20 rating, which, as ControlByte notes, is fine inside a protected enclosure. If you need 24 VDC in dusty or wet areas, you either mount an IP20 DIN-rail unit in a sealed enclosure or choose a supply with a higher IP rating, such as IP65, depending on the environment. That aligns with CNNVVV’s observation that 24 V supplies can be used outdoors only when they are specifically designed and rated for it.

The other benefit of DIN-rail mounting is maintainability. When a supply does eventually fail, you want a technician to be able to isolate it, loosen a few terminal screws, unlatch it from the rail, and swap in a replacement without disassembling half the cabinet. Laying out the panel with that replacement path in mind pays dividends many years after the machine ships.

Grounding, Isolation, and Noise on the 24 V Rail

Grounding is where theory and field practice often clash. The documents summarized by ControlByte and Schneider Electric focus on standards-compliant isolation and proper protective grounding. In parallel, an experienced practitioner writing on the MrPLC forum describes running many modern installations with the 24 VDC common left ungrounded, especially when using switch-mode supplies and NPN inputs.

The standards view starts with PELV. To qualify, the 24 VDC side must be safely isolated from mains through appropriate transformer design and reinforced insulation. That isolation does not, by itself, tell you whether to bond the 24 V negative to protective earth; it simply ensures that even if the primary side suffers a fault, dangerous voltages do not appear on your control wiring. ControlByte points to EN 50178, EN 60204, and related standards as the references for this safe separation and protective low-voltage concept.

Schneider Electric’s operator display documentation adds another dimension: the separation of signal ground and functional ground inside the device, and the requirement to bond the functional ground terminal solidly to earth. It warns that failing to ground that terminal can lead to excessive electromagnetic interference. That guidance extends to the power supply feeding the device: earth or functional ground terminals on the supply need to be bonded correctly to the cabinet ground network.

The MrPLC perspective focuses on the DC side. The author notes that in older systems with linear 24 V supplies it was common practice to bond the DC negative to ground. In more recent installations, using modern switch-mode supplies with galvanic isolation, they prefer to leave the DC side ungrounded. They explicitly recommend not grounding the 24 V common in systems with NPN inputs and highlight that intrinsic safety barriers often demand an ungrounded 24 V system for certification reasons. In their experience, with good wiring, shielding, and panel bonding, ungrounded 24 V rails are robust even in noisy chemical plant environments.

Taken together, the picture is nuanced. The protective earth and functional ground connections required by equipment and standards are not optional; you bond what the manufacturer tells you to bond. Whether you also reference the 24 V negative to ground is a design choice driven by input circuit type, intrinsic safety considerations, and noise behavior. In my own work, I follow the manufacturer’s grounding diagrams first, then consider whether a single-point bond between 24 V negative and ground is beneficial or prohibited. What I avoid is ad hoc multiple bonds at different points in the cabinet, which is a great way to create ground loops.

Noise and surge suppression round out the grounding story. Schneider Electric recommends routing DC power cables away from high-voltage mains wiring, keeping the DC cables as short as practical, twisting conductors near the supply, and using shielded cables when separation is impossible. They also suggest adding noise filters, surge protection devices, and ferrite cores on the power cable in high-noise environments. A surge protection device tied to a solid ground connection near the equipment helps control lightning-induced surges and other transients. These measures are more effective and predictable than simply “grounding more.”

Environment, Cooling, and Reliability

Power supplies are converts of energy, but they also convert some of it into heat. Both CNNVVV and CirkitDesigner’s 24 VDC notes emphasize that overheating is usually a symptom of insufficient ventilation or overloading. The fix starts at the selection stage and continues through mechanical design.

From a selection standpoint, the CNNVVV guide urges buyers to look at efficiency ratings, noting that higher efficiency means less energy wasted as heat and lower long-term operating cost. Certifications such as Energy Star or 80 PLUS, along with a high power factor, are signals of good energy performance. In an industrial panel, efficiency also translates to cooler operation, which improves reliability of both the supply and nearby electronics.

Environmental ratings matter as well. ControlByte points out the reliance on IP20 devices inside protected cabinets and the need for higher IP ratings when the supply itself is exposed to dust or moisture. The Ecostruxure guidance adds the importance of conductor temperature ratings and mentions that power conductors should be rated for at least about 167°F. That is consistent with the internal temperatures supplies can see in a warm cabinet on a hot day. In practice, this means choosing both the supply and the wiring with the upper end of expected ambient conditions in mind, not just the datasheet “room temperature” scenario.

Derating is the manufacturer’s way of telling you how much load a supply can safely carry as ambient temperature rises. ControlByte notes that higher cabinet temperatures reduce efficiency and can require the supply to be oversized. As a systems integrator, I do not treat those derating curves as fine print; if a machine will run in a warm plant or inside a sealed enclosure, I size the supply and any forced ventilation accordingly.

CirkitDesigner’s FAQ-style discussion of 24 V supplies reinforces a simple rule: if a supply is running hot, first check ventilation and load. Confirm that the total current draw is within the supply’s rating and that the supply has adequate airflow. If it still overheats, the guidance is to consult the manufacturer rather than simply accepting the condition. Running a power supply permanently at or beyond its thermal comfort zone is a reliable way to shorten its life.

Outdoor use is another environmental dimension. CirkitDesigner warns that standard 24 VDC supplies are not suitable for outdoor wet or damp environments unless explicitly rated for it. CNNVVV echoes this point by recommending that buyers pay attention to ingress protection ratings for outdoor or harsh industrial use. For control systems, the straightforward solution is to keep the power supplies inside appropriately rated enclosures and bring only the low-voltage circuits into the field.

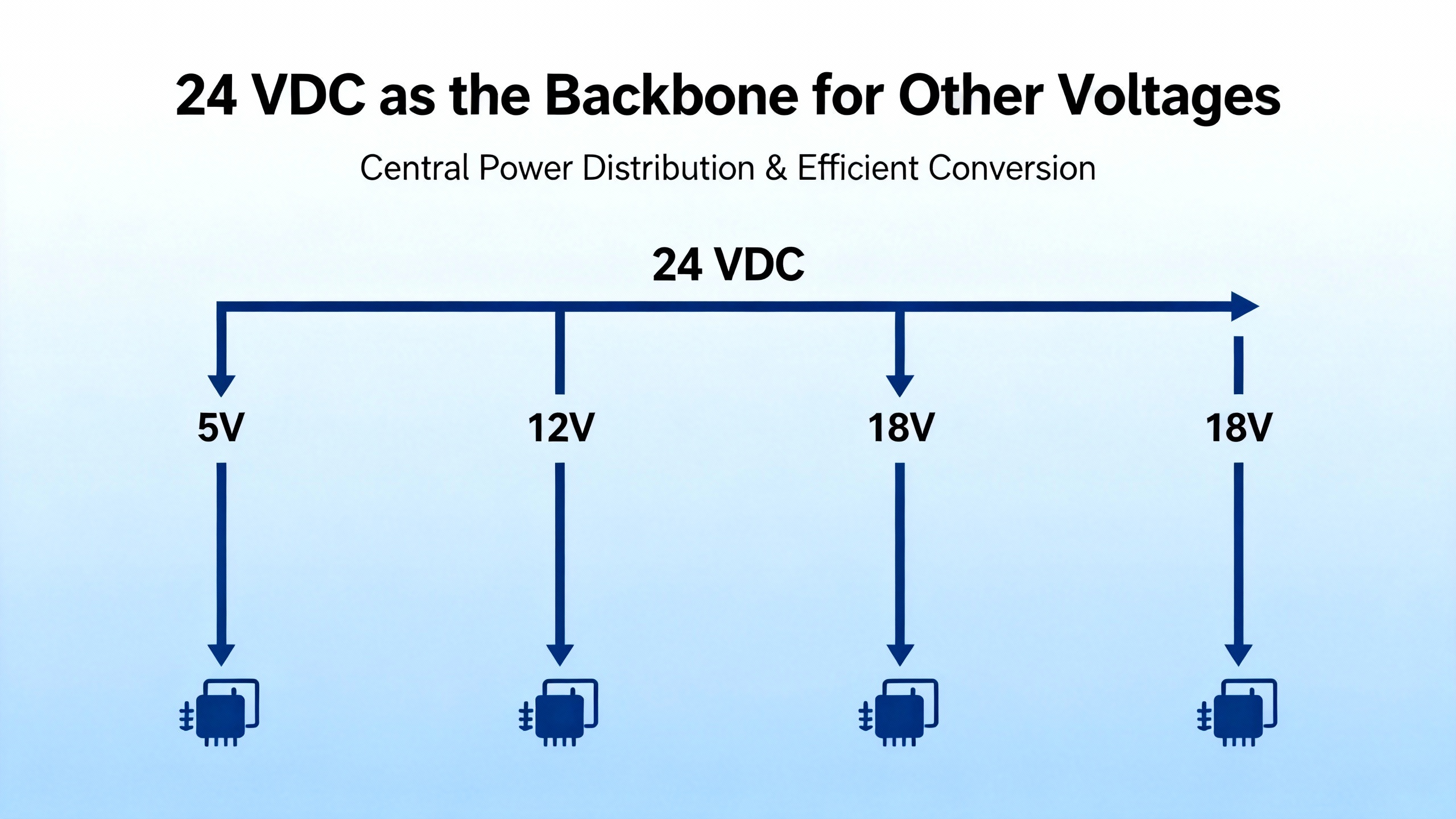

Using 24 VDC as the Backbone for Other Voltages

In many panels, 24 VDC is not the only voltage you need. Embedded controllers, communication modules, and development boards like the Arduino UNO still require lower voltages. CirkitDesigner notes that an Arduino UNO typically runs at 5 V and must not be powered directly from a 24 VDC supply; you need a suitable voltage regulator or DC-DC converter to step down the voltage safely.

The Electronics StackExchange discussion on providing both 24 VDC and 5 VDC lays out a clean architecture: a single external or DIN-rail 24 V supply feeding a buck converter to generate the 5 V rail inside the cabinet. The analysis there shows that a 5 V, 2.5 A load corresponds to 12.5 W; with a moderately efficient buck converter, the 24 V supply sees around 16 W, and the converter dissipates only about 3 to 4 W as heat. That loss is usually less than what you would see from a separate 5 V supply handling mains directly, and it keeps all mains wiring confined to one unit.

From an integration standpoint, this approach also consolidates maintenance. When you return to the panel years later, you see a clear hierarchy: mains to 24 V supply on the DIN rail, then 24 V rail feeding DC-DC converters and downstream electronics. You can meter and isolate the 24 V backbone quickly, and there is only one device exposed to the mains within that part of the cabinet.

Installation, Commissioning, and Maintenance

Industrial documentation and field experience agree on the basic discipline needed to install and maintain 24 VDC power supplies correctly.

On the installation side, CNNVVV and Linklieo both stress de‑energizing circuits before wiring, verifying the absence of voltage with a meter, wearing appropriate personal protective equipment, and following local electrical codes. They describe the conventional terminal labeling: mains input terminals marked for live, neutral, and ground, and DC output terminals labeled positive and negative. The Ecostruxure guidance adds the functional ground terminal for some devices, which must be bonded to an appropriate grounding point.

Wire sizing and preparation are not trivial details. Schneider Electric’s notes specify using copper conductors within an appropriate gauge range, avoiding aluminum or poorly twisted wire ends that could lead to short circuits. Those reminders may sound obvious, but I have seen enough scorched terminal blocks to know that undersized wire, bad stripping, and loose terminations are still common failure modes.

For commissioning, CNNVVV recommends verifying the output voltage with a multimeter at the load terminals and watching for abnormal noises, overheating, or fault indicators. In my projects, I also like to measure the current draw of major loads or at least ensure that the supply’s built-in indicators show a healthy operating range under worst-case conditions. If a supply is already near its limit during factory testing, it will not age gracefully on a hot plant floor.

Routine maintenance focuses on the basics. CNNVVV lists checking for loose connections, blown fuses or tripped breakers, signs of overheating, and visible physical damage. The CirkitDesigner guidance adds that persistent overheating after you have verified proper loading and ventilation is a sign to involve the manufacturer. Power supplies are not meant to be component-level repair projects in the field; if you suspect internal damage, replacing the unit is almost always the right move, especially in safety-related applications.

When troubleshooting a dead or unstable 24 V rail, I walk a simple path. Confirm the presence of mains at the supply input. Check any primary-side fuses. Measure the DC output at the supply terminals with no load, then under load. If the supply itself passes those tests, start moving downstream: check distribution fuses or breakers, terminal blocks, and field wiring. This methodical approach, combined with the built-in status LEDs and diagnostic notes in the manuals, usually gets to the root cause without guesswork.

Short FAQ for Project Teams

Do I really need an industrial-grade DIN-rail supply, or will any 24 V unit do?

For machine control and safety circuits governed by IEC 60204-1, you need a supply that provides safe isolation and complies with the relevant EN and IEC standards. As ControlByte points out, low-cost supplies intended for LED or IT use may not meet those requirements even if their voltage and current ratings look similar. In my experience, using a non-industrial supply in a control cabinet often shows up later as nuisance trips, unexplained communication problems, or failures under surge conditions. For anything connected to PLCs, safety devices, or operator interfaces, an industrial DIN-rail supply is the right starting point.

How much headroom should I design into the 24 V rail?

Both the CNNVVV and ControlByte guidance recommend sizing the supply above the calculated load. A practical approach is to calculate your total current or wattage, consider inrush and short-term peaks, and then select a supply that can deliver modestly more than that figure. In many cabinets, aiming for a typical load around eighty to ninety percent of the supply’s rating provides a good balance between cost and reliability. That margin also gives you room for future additional devices without replacing the supply.

Should I bond the 24 VDC negative to ground?

There is no one-size-fits-all answer. The standards demand correct bonding of protective earth and functional ground according to each device’s manual. Whether to tie the 24 V negative to that ground is a system design choice. Schneider Electric’s material focuses on grounding functional ground terminals to control noise, while an experienced practitioner on MrPLC reports good results with ungrounded 24 V commons in modern systems, especially where intrinsic safety barriers require it. In my projects, I follow manufacturer recommendations and, where allowed, use a single, deliberate reference point if I need to bond the DC side to ground, avoiding multiple unintended bonds that create loops.

Closing Thoughts

A 24 VDC DIN-rail power supply is not the most expensive component in a control cabinet, but it is one of the most important. When it is selected with proper attention to standards, sized with realistic headroom, mounted with airflow and serviceability in mind, and grounded thoughtfully, it quietly does its job for years. When it is treated as a commodity brick, every weakness in its design and installation shows up at the worst possible time.

If you are designing or upgrading a cabinet, treat the 24 V rail as the backbone of the system, not an afterthought. Choose industrial-grade supplies, wire and ground them the way the best-practice documents describe, and think about the technician who will be standing in front of that panel on a holiday weekend at 2:00 PM. If your design makes their life easier, your machine will almost always run better.

References

- https://www.slac.stanford.edu/grp/lcls/controls/global/hw/users_guides/plc/1756-in078_-en-p.pdf

- https://www.plctalk.net/forums/threads/24vdc-control-panel-layout-questions.78307/

- https://jmacfiles.s3.amazonaws.com/docs_AQD6_Installation_Manual.pdf

- https://downloads.cabinetparts.com/auto/trescobyrevashelf-I-1224DCH3-0423.PDF

- https://www.instructables.com/Two-ATX-PSU-One-juiced-24-V-DC-PSU/

- https://www.justanswer.com/electrical/lnxno-control-cabinet-24vdc-power-supply.html

- https://linklieo.com/how-to-connect-a-server-power-supply-for-24v-a-complete-guide/

- https://docs.cirkitdesigner.com/component/f5d3cafc-79dc-4f24-8470-5eb27d3e655a/power-supply-24-vdc

- https://cnnvvv.com/news/24v-power-supply-essential-guide-for-efficient-and-reliable-power/

- https://controlbyte.tech/blog/select-a-24v-dc-power-supply-for-the-automation-system/

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment