-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Express GE Fanuc PLC Parts: Accelerated GE Automation Component Delivery

When a GE Fanuc PLC rack goes down in the middle of a production run, the difference between “next week” and “tomorrow morning” can be hundreds of thousands of dollars. I have watched plants stand idle because a single failed CPU or power supply took out an entire line, and the replacement part was sitting in a warehouse three states away, trapped behind slow processes and vague promises.

Express delivery of GE Fanuc PLC and related GE automation components is not just a shipping upgrade. It is a disciplined way of designing your spare-parts strategy, your logistics, and your supplier relationships so that critical hardware moves at the speed your production reality demands. In this article, I will walk through what “express” really means in our world, how GE and its partners have structured their own parts support, and how to design an accelerated GE Fanuc parts program that actually holds up when a control cabinet goes dark.

Why Speed Matters For GE Fanuc PLC And Control Parts

Manufacturing cycle time is a core performance metric. When a control failure stops production, cycle time does not just stretch; it explodes. Research on industrial robots and automation points out that a single robot cell can move the work of several operators while running around the clock. When that cell is locked out waiting for a replacement module, you are losing output every minute, and the impact cascades into missed shipments, overtime, and firefighting on the planning side.

Studies of obsolete automation parts underline how much risk sits in aging control hardware. Many PLCs have a typical lifecycle on the order of ten to fifteen years before the original manufacturer starts to taper support. Articles on sourcing obsolete automation parts highlight how failures on legacy platforms dramatically increase the likelihood of extended downtime, especially when the failed units are no longer in active production and must be sourced through specialist channels. In that context, expedited delivery is less of a convenience and more of a core risk-control measure.

This is why I treat every GE Fanuc and GE Automation control asset as part of a time-sensitive chain, not a static piece of hardware. You do not just need a replacement part; you need a replacement part that can reach your plant within a window that keeps the production schedule intact.

What “Express” Really Means In Industrial Parts Logistics

The term “expedited” gets used carelessly. In consumer e‑commerce it can mean almost anything faster than the cheapest ground service. In industrial logistics, reputable sources define expedited shipping as a premium service designed to significantly shorten transit time compared with standard options, with typical windows in the range of one to three business days. Standard freight, in contrast, often sits in the three to seven day band or longer, especially when shipments pass through multiple terminals and cross-dock hubs.

Several supply chain and logistics publications draw a further distinction between expedited and express. When both are offered, express is usually the fastest tier, often next-day or even same-day for certain lanes, while expedited is a broader category that simply guarantees “faster than standard.” For our purposes, “express GE Fanuc PLC parts” should mean an offering anchored around one to three day delivery as the baseline, with the ability to push into overnight territory when inventory location and carrier capacity allow.

It is also important to understand how expedited services achieve these timelines. Industry guides point out that expedited loads typically use more direct routes, fewer handoffs, and dedicated capacity where practical. Instead of a part riding through a hub-and-spoke network with multiple touches, it may travel on a dedicated truck or priority air service with minimal handling. That reduction in handling not only speeds arrival; it also lowers the risk of damage or loss, which is critical when you are shipping expensive CPU modules or communication cards.

How GE Fanuc And GE Automation Built The Foundations For Faster Support

Well before “same-day delivery” became a retail headline, GE Fanuc Automation was structuring its own parts support program around uptime. A GE Fanuc CNC parts support brochure from the late 1990s describes one of the industry’s most comprehensive support ecosystems focused on keeping CNC equipment running. The key building blocks are surprisingly modern.

One element is a structured Spare Parts Analysis. GE Fanuc personnel review a specific control or an entire operation and recommend spare-parts stock lists and inventory levels that align with uptime targets. Rather than guessing at which boards and drives to hold, customers get a structured view: what is installed, what fails most often, what has longer lead times, and what must be on the shelf locally. For GE Fanuc CNC users, that analysis became the foundation for rational stocking and faster recovery when failures hit.

Another element is regional warehousing. GE Fanuc established warehouses across the Americas, strategically stocked with commonly used parts. The idea was straightforward: put high-demand items closer to where customers operate so that the last mile can move quickly. Warehouse contracts could define customized inventories and build reduced delivery times directly into the agreement, making “fast” an explicit, contractual attribute instead of a vague promise.

GE Fanuc also offered emergency parts service around the clock, with counter-to-counter and door-to-door options intended to get controls back up and running as quickly as possible. Paired with blanket purchase orders that streamline the paperwork, this parts support model shows that the company understood the relationship between logistics friction and plant downtime long before today’s emphasis on real-time visibility.

On the software side, GE Fanuc’s integration of its Cimplicity control suite with Datasweep’s web-based manufacturing and repair analytics into a combined Cimplicity Advantage solution illustrates the same philosophy. The integrated system linked plant-floor control with broader supply chain data to help customers bring products to market faster, increase quality, reduce work-in-process, and cut warranty costs. A pilot deployment at a GE facility reported high double-digit yield improvements in roughly twelve weeks by mining production data for root causes of variability. That type of integration—control plus information plus logistics—sets the pattern for modern accelerated parts programs.

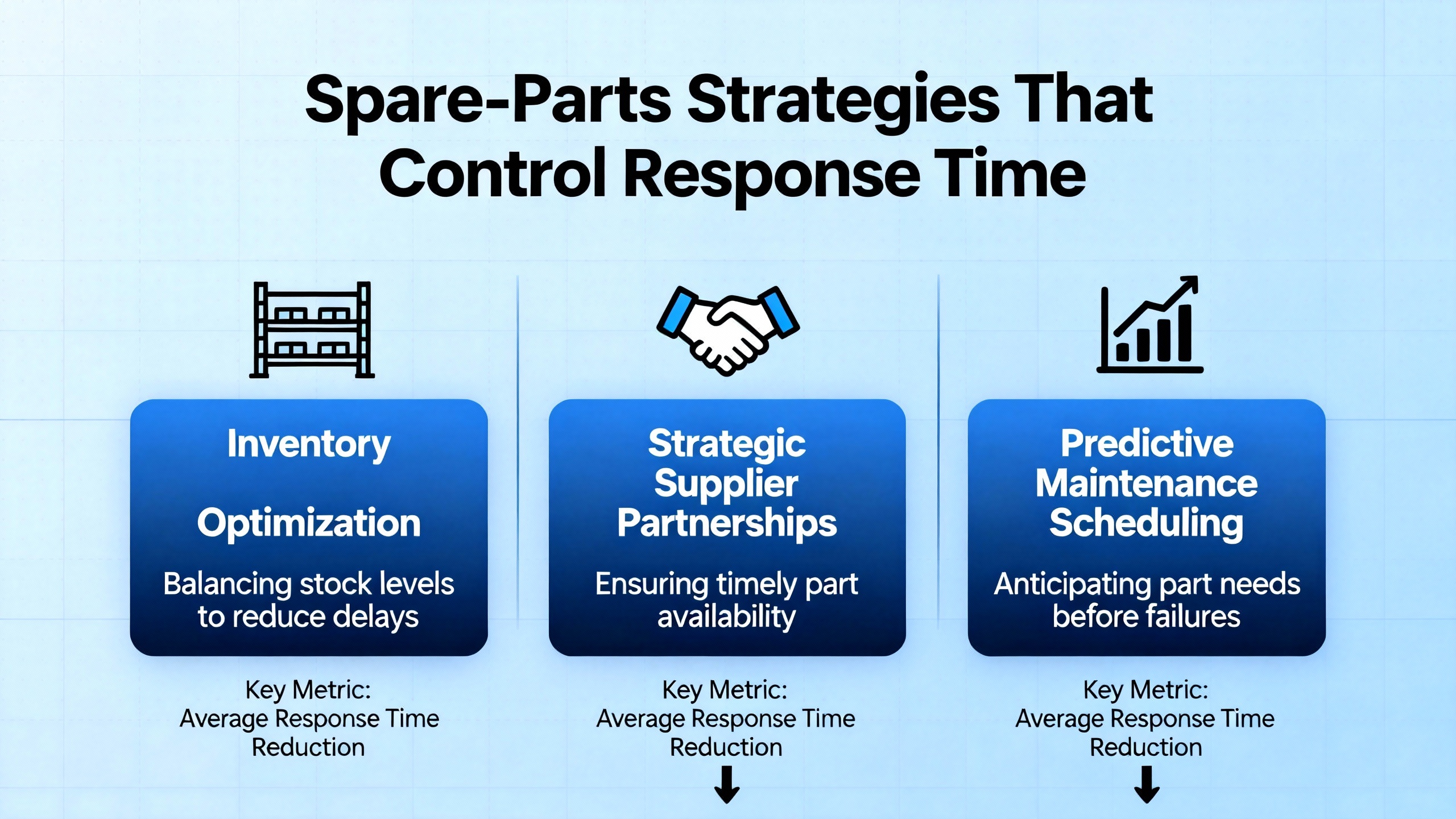

Spare-Parts Strategies That Control Response Time

When you step back from individual shipments, the real determinant of how fast you can get a GE Fanuc PLC part is your overall spare-parts strategy. A recent GE Vernova article on control-parts management for power plants lays out three archetypal approaches: classic on-site stocking, centralized storage, and vendor-managed inventory. Although that piece focuses on power generation, the logic applies directly to GE Fanuc PLC and CNC hardware in any industrial environment.

Here is a simplified view of those models and how they affect response time.

| Stocking model | Typical response time | Main advantages | Key trade-offs | Best suited for |

|---|---|---|---|---|

| Local on-site stock | Immediate; minutes to hours once failure is identified | Fastest possible recovery; zero dependence on freight | High capital tied up in inventory; warranty clock may run before use; risk of parts that never get installed | Truly critical controls where downtime is intolerable |

| Centralized warehouse (single country) | Generally a few days for delivery | Inventory efficiency across multiple plants; avoids customs and long-distance delays | Not fast enough for zero-tolerance processes; requires coordination across sites | Operators with several plants and moderate downtime tolerance |

| Vendor-managed inventory (VMI) | Often around one to two weeks | Lower upfront capital; supplier manages stock profile; better warranty utilization | Lead time is significantly longer; unsuitable for immediate repairs; requires strong supplier reliability | Less critical applications and components with some buffer |

GE Vernova’s control-parts guidance emphasizes aligning the chosen model with your downtime tolerance, cash constraints, and regulatory or tax environment. In other words, there is no single “best” answer. For a bottling line running three shifts where a failed GE Fanuc CPU will idle hundreds of workers, it is hard to argue against local spares on the shelf. For less critical IO modules spread across multiple facilities, a centralized or vendor-managed pool can make more sense.

In my integration projects, the strongest results usually come from hybrid strategies. Critical PLC and CNC control elements are stocked locally in at least one spare per production-critical asset. Noncritical or easily bypassed devices move into a centralized or vendor-managed pool, as long as the service level agreements and real-world performance of the supplier match the promised timelines.

Designing An Accelerated GE Fanuc Parts Program

Express delivery is the last step, not the first. To make accelerated GE Fanuc PLC parts a reliable reality rather than an emergency scramble, you need a structured program that spans procurement, maintenance, engineering, and logistics.

One procurement-focused guide defines expediting as a proactive function that ensures timely delivery of materials and services while maintaining quality, not simply “pushing suppliers harder.” That process starts with preparation: identifying critical items, gathering order data, and setting clear communication channels. For a GE Fanuc environment, that means building and maintaining a clean, accurate asset inventory and a living list of part numbers, firmware levels, and known replacements.

Cross-functional collaboration is equally important. Effective expediting models bring project management, engineering, document control, and procurement into a shared view of what “urgent” really means. If every part is marked critical, nothing is. When your maintenance team, integrator, and buyer agree upfront which GE Fanuc PLCs, motion controllers, and HMIs are truly time sensitive, you can reserve express freight for the loads where it pays for itself.

Logistics research on expedited shipping stresses the importance of treating expediting as a strategic tool, not a last resort. That means analyzing the cost of a plant stoppage, lost sales, and chargebacks from missed retailer windows and comparing those costs with the premium for faster transport. For an automotive line, paying a high expedited freight bill to avoid a shutdown almost always pencils out. For a single packaging cell with built-in redundancy, the calculation may be different.

Technology should underpin this strategy. Articles on streamlining logistics show how transportation management systems, warehouse management systems, and AI-driven analytics can combine to cut logistics costs and inventory levels while improving visibility. GE Appliances’ participation in the Freight Logistics Optimization Works program is a good example of using forward-looking and historical data on freight flows to understand what is heading to which ports in the next two, four, or six weeks and to reroute when disruptions hit. The same mentality applies to parts: if you know where demand is likely to arise, you can stage GE Fanuc components closer to those nodes and reserve express freight for genuine surprises.

Practical Ways To Cut Lead Time On GE Fanuc PLC Components

There are several very practical steps you can take to shrink the time from failure to restored operation, especially if you rely heavily on GE Fanuc PLC and CNC systems.

Start with a disciplined asset and spare-parts inventory. A guide on avoiding downtime from obsolete automation components recommends a full production-line audit and a detailed asset inventory including part and serial numbers, installation dates, maintenance history, and expected lifespan. Many plants are surprised, once they do the work, to discover how many different generations of hardware they are running. With a clean inventory in hand, you can identify which GE Fanuc platforms are approaching end of life, which ones have readily available replacements, and which ones belong on a watch list because support is dwindling.

Once you have that visibility, categorize components by risk. High-risk parts are those without readily available alternatives, where failures will stop production outright. Low-risk parts either have drop-in replacements from current product lines or can be bypassed temporarily. High-risk GE Fanuc components are prime candidates for local stocking and pre-arranged express replenishment. Low-risk ones can sit in a centralized or vendor-managed pool, perhaps with a slower service tier.

Next, look at your buying methods. A machining supplier’s guide to reducing CNC lead times describes several underused purchasing approaches that translate well into electronics and control parts. Call-off orders involve placing a larger overall order but drawing down in smaller deliveries as needed, securing bulk pricing while preserving responsiveness. Schedule orders go further by locking in a delivery timetable in advance so that shipments of controls line up with broader project milestones. Kanban-based ordering pushes toward true just-in-time management, triggering replenishment when on-hand inventory drops below a defined threshold. For GE Fanuc spares, blending these methods with clear min/max levels can reduce effective lead time to a day or two because the physical stock already lives near your plant, and the “express” leg is just the final hop.

Supplier quality and testing protocols also play a direct role in lead time. One obsolete-parts specialist notes that its typical offering includes multi-point functional testing with real-world simulation and a strong warranty, often up to twenty-four months. That sort of quality focus means fewer DOA boards, fewer returns, and fewer cases where a part arrives “fast” but fails at power-up, forcing you into another emergency order. From a lead-time perspective, “right first time” often matters more than shaving one more day off transit.

Finally, do not neglect communication. Articles on CNC lead time and supplier quality stress the value of transparent, proactive communication from initial RFQ through shipment and installation. For GE Fanuc PLC parts, insist on clear order acknowledgments, realistic ship dates, and real-time tracking. On the plant side, make sure your own requests are complete and unambiguous: correct part numbers, clear failure context, and any environmental details that could affect replacement choice. Every round of clarification adds hours you cannot spare in a line-down situation.

What To Expect From An Express GE Fanuc PLC Parts Partner

When you evaluate partners offering express GE Fanuc PLC and automation components, you should benchmark them against the best practices described above and against what GE itself has modeled in its own parts programs.

You should expect a structured front-end analysis rather than ad hoc suggestions. A thorough spare parts analysis, similar in spirit to GE Fanuc’s historical approach, will look at your installed base and recommend a specific mix of on-site, centralized, and vendor-managed spares. It will also flag obsolete or at-risk items so you can plan replacements before they become emergencies.

You should expect regional inventory. Partners who serve the Americas effectively usually maintain warehouses positioned near major industrial corridors and ports, stocked with the GE Fanuc and related controls that fail most often. This regional footprint is what makes one to three day delivery via ground or short air legs realistic, instead of promising miracles out of a single distant depot.

You should expect clear service tiers. That means defined order cut-off times for same-day shipment, named carriers and service levels for different zones, and written expectations for response when you call in a line-down event after hours. Many logistics experts point out that expedited carriers operate under tighter windows and higher performance pressure than standard services, so a strong partner will know exactly which modes and lanes deliver reliably for your particular plants.

You should expect integrated quality and logistics. The most effective partners I have seen blend technical support, field service, repair, parts, and training with logistics capabilities and digital tools. They use transportation management systems to select routes, provide consolidated billing, and offer real-time tracking. They also market their spare-parts programs with concrete performance metrics such as on-time delivery percentages and perfect-order rates. In one custom manufacturing context, for example, a provider reports shipping ninety-seven percent of parts on time and achieving over ninety-five percent perfect orders, defined as on time and in full. While that example is not specific to GE Fanuc hardware, it illustrates the type of quantitative accountability you can and should ask for.

Finally, you should expect around-the-clock escalation paths. The GE Fanuc CNC support material from the late 1990s highlighted emergency parts service running twenty-four hours a day, seven days a week, underscoring that control failures do not respect office hours. Your modern GE Fanuc PLC parts partner should meet or exceed that baseline.

Balancing Express Freight With Smart Design And Modernization

It is tempting to see express parts delivery as the answer to every downtime risk, but freight alone cannot overcome chronic design and lifecycle issues. Several reputable sources in machining and control fields emphasize the value of design-for-manufacturability, preventive maintenance, and modernization.

On the design side, better part and panel design can reduce failure rates and ease replacement. Clear documentation, consistent part numbering, and avoiding unnecessary variation in control hardware all pay off when you are trying to stock and source spares. GE Appliances, for example, uses product architecture and parts optimization to reduce proliferation of unique parts and to reuse existing variants wherever possible. That same attitude applied to GE Fanuc PLC hardware translates into streamlined spare-parts requirements and a tighter, faster supply chain.

On the modernization side, vendors like FANUC highlight how retrofitting legacy CNC equipment with modern controls, servos, and cabling can cut cycle times by as much as fifty percent without the expense of new machines. From a parts perspective, retrofits also move you away from the most obsolete generations of hardware, where every express shipment is a small emergency, and into current platforms with better support and more predictable availability.

Layered on top of this, logistics and ERP providers showcase how digital tools can cut logistics costs by double-digit percentages and inventory levels by roughly a third, while predictive maintenance and AI-driven analytics reduce unplanned downtime. Bringing those capabilities to bear on your GE Fanuc installed base helps you see which assets are drifting toward failure, which parts are consuming your maintenance hours, and where to focus your express and stocking muscle.

FAQ: Express GE Fanuc PLC Parts And Accelerated Component Delivery

When is it actually worth paying for express GE Fanuc PLC parts? The right time is when the cost of not expediting clearly exceeds the premium you will pay for the faster service. Logistics experts recommend quantifying the impact of a missed shipment or prolonged line stoppage in terms of lost sales, penalties, and restart costs. If a day of downtime on a GE Fanuc-controlled process line will cost tens or hundreds of thousands of dollars, and an express shipment will cost only a small fraction of that, the math is straightforward. On the other hand, if the failure affects a noncritical cell with plenty of buffer, you may be better off using standard freight and protecting your logistics budget.

How fast is realistic for GE Fanuc PLC replacements under an express program? Industry resources on expedited shipping consistently describe one to three business days as a typical expedited window for domestic shipments, with overnight services available on many lanes when inventory is already in the right region. Some specialized expedited services can deliver within roughly twenty-four to forty-eight hours by using optimized routes and dedicated capacity. The real constraint is rarely the carrier; it is where the part is physically stored and how quickly your supplier can process the order. That is why regional warehouses and clear cut-off times matter more than marketing slogans.

Can you rely solely on vendor-managed inventory for GE Fanuc PLC parts? Vendor-managed inventory programs, like the PartSmart approach described in GE Vernova’s control-parts article, can be powerful tools for reducing capital outlay and avoiding obsolescence. The trade-off is lead time. VMI arrangements typically deliver parts in about a week or two, which is perfectly acceptable for many maintenance activities but too slow for genuine emergencies. In practice, the most resilient plants use VMI for the bulk of their spares portfolio while still holding a small, carefully chosen set of GE Fanuc PLC and control components on site for immediate use when critical systems fail.

In the end, express delivery should be part of a layered strategy rather than a single silver bullet.

A well-run plant does not rely on luck when a GE Fanuc PLC fails at 2:00 AM. It relies on a clear spare-parts strategy, trusted partners with regional stock, disciplined expediting practices, and the willingness to pay for speed when speed actually matters. If you take the time now to map your GE Fanuc installed base, align your stocking models with downtime risk, and choose partners who can truly deliver in one to three days, you will find that “express GE Fanuc PLC parts” stops being a marketing phrase and becomes part of how you quietly keep the plant running while everyone else sleeps.

References

- https://www.globalbioenergy.org/expedited-shipping-guide/

- https://www.cnchonscn.com/a-delivery-control-of-cnc-machining-in-spare-parts-manufacturing.html

- https://artofprocurement.com/blog/supply-advancements-adjustments-in-the-ge-appliances-supply-chain

- https://www.pentaprecision.co.uk/resources/cnc-machining-lead-times-explained-how-to-get-your-parts-faster

- https://www.controleng.com/ge-fanuc-datasweep-integrate-manufacturing-supply-chain/

- https://cowtownexpress.com/blog/expedited-shipping-101-a-full-guide

- https://www.dat.com/resources/expedited-shipping-benefits-best-practices

- https://www.fictiv.com/articles/our-top-three-tips-for-reducing-cnc-lead-time

- https://kesugroup.com/how-to-avoid-delivery-delays-when-choosing-a-cnc-machining-factory/

- https://www.machining-custom.com/blog/solve-the-problem-of-delivery-delay-of-cnc-machining-parts.html

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment