-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Fast Delivery Rockwell Automation Components: Expedited RA Parts Service

I have stood on plant floors at 2:00 AM with production at a standstill, a control panel open, and a maintenance lead asking one question: how fast can we get the right Rockwell Automation part, installed, configured, and running safely? When the answer is measured in hours instead of days, it is never because we got lucky. It is because a disciplined expediting model was already in motion, the supplier network was pre-aligned, documentation and approvals were ready, and logistics were treated like a first-class engineering problem. This article outlines a practical, field-proven approach to expediting Rockwell Automation components so you restore operations without trading speed for risk.

What “Expedited” Really Means in Industrial Procurement

Expediting is not simply paying for overnight shipping. As production management research summarized by Bizmasterz explains, expediting is the active monitoring and acceleration of critical materials, tasks, and supplier deliveries to meet schedule commitments. In practice that means you prioritize urgent orders, resequence plans, secure supplier commitments, consider alternate qualified sources, and use faster shipping only when it meaningfully advances the promise date. Current SCM describes expediting as a proactive procurement function that ensures timely delivery of materials, services, and required documents while maintaining quality standards, and emphasizes clear communication, documented status, and measured results.

The simple definition matters because it re-centers the conversation on throughput, not tracking numbers. For Rockwell Automation components, the expediting discipline should cover the full chain. It starts with clean requirements and documentation, continues through supplier confirmation and inspection readiness, and ends with installation sign-off and post-startup stabilization. A good expediting program also measures On-Time Delivery and On-Time In-Full, tracks expediting lead time from the moment a risk is flagged to the event being cleared, and scores supplier responsiveness and quality compliance. With those data points, you eliminate surprises and build playbooks that get faster with every use.

The RA Parts Reality: When Speed Matters Most

Emergency maintenance is the obvious case for expediting. A production line that cannot produce until a PLC rack, I/O card, drive, HMI, safety relay, or contactor is replaced will justify premiums. Capital projects often justify expediting as well, particularly when a cutover window is short, the work is sequenced tightly with other trades, or the controls scope is driving commissioning. Compliance events can also trigger expediting when safety or regulatory obligations require a rapid component substitution, provided the replacement has documented equivalence and approvals. Finally, obsolescence and lifecycle shifts sometimes force a last-minute pivot when a standard item goes on extended lead time and an alternate must be evaluated quickly.

In all of these scenarios the same risks recur. If you chase speed without governance, you can end up with inconsistent firmware revisions, incompatible accessories, counterfeit risk, or documentation gaps that slow qualification. The better path is to define a single goal upfront: restore a safe, validated state on the shortest credible schedule while preserving traceability, configuration control, and maintainability.

A Proven Expediting Model for RA Components

The process that has served me best begins with triage. The first question is always whether the equipment can be made safe and partially restored without new hardware. If it cannot, classify the failure by process criticality and by the risk of unintended consequences during installation. Functional safety circuits, motion applications, and network backbones deserve a higher level of scrutiny than non-critical auxiliary devices. This classification will drive your sourcing posture and your test strategy.

Sourcing then moves in two tracks. The preferred route is always an authorized channel with confirmed factory provenance. For many organizations that means a short list of distributors with current agreements, agreed escalation paths, and pre-cleared alternate SKUs that engineering has vetted for function and compliance. At the same time, a qualified alternate-source path can run as a time hedge. That track demands a more rigorous acceptance process, including serial number capture, visual and functional inspection, and immediate proof of authenticity. Current SCM’s guidance on documentation and communication is invaluable here. Keep purchase order history, supplier commitments, and inspection records in the same place so that decisions under time pressure do not defeat traceability.

Once supply is in motion, compress time across every controllable segment. Purchase order automation helps by validating item numbers and terms and by routing exceptions quickly; Leverage AI’s supply chain guidance calls this out as a control tower pattern that eliminates back-and-forth and creates auditable trails. Logistics should match urgency and distance rather than defaulting to the most expensive option. Next-flight-out can beat ground for long hauls; a local will-call with a certified driver can beat air for regional moves; a dedicated hot shot can beat both when you control dispatch and route. Communication beats waiting every time. A twice-daily status cadence with the supplier, the logistics provider, and the site team turns “we hope” into “we know,” and it allows you to pivot before hours go by.

The Data Advantage: Use AI and Real-Time Signals to Remove Days

When a line is down, time is money and information is time. AI-enabled supply chain practices, as reported by Leverage AI, reduce delays through predictive risk detection, demand and inventory forecasting, automated purchase orders, real-time shipment monitoring, supplier performance management, and dynamic routing. The reported impact is significant, with companies citing up to fifty percent lower operating costs and as much as ninety-six percent fewer stockouts when the analytics are integrated with operations. Those claims must be applied carefully in heavy industry, but the pattern translates well to RA components.

From a parts expediting perspective, the wins are straightforward. Predictive disruption detection can warn you that a winter storm may close a regional hub and that a route change is cheaper than a day of downtime. Forecasting that blends historical work orders and seasonal shutdowns can signal early reorder points for spares with long lead times. Purchase order automation validates item numbers and directs exceptions to humans only when something is off, and it preserves clean records. Real-time monitoring and dynamic rerouting enable a true end-to-end estimated time of arrival that the controls team can plan around, including night shift coverage. Supplier scorecards with On-Time In-Full, response time, and quality compliance let you decide which partner gets the hot job on a Sunday night. Even document flows can be automated with intelligent document processing; teams that move paper by email are often the same teams that lose hours chasing signatures and customs data that should have been captured upstream.

It is tempting to treat these capabilities as nice-to-have. In practice they are the difference between a six-hour recovery and a one-day recovery, because most of the calendar time in urgent parts flow is hidden in handoffs, not in the carrier’s truck.

Warehouse and Logistics Moves that Actually Cut Calendar Time

Shipping and handling steps destroy more schedules than suppliers do. Burq’s logistics guidance notes that last-mile delivery can account for a significant share of supply chain costs, and a large share of delays come from manual, fragmented workflows. SC Solutions observes that delayed deliveries are common enough to be measurable and that process discipline across order processing, fulfillment, and carrier handoffs is the antidote. Bring that logic into your MRO parts flow and you eliminate waste you did not know was there.

On the warehouse side, Oracle NetSuite explains that warehouse automation does not have to start with robots. A warehouse management system that automates data capture, inventory control, and analysis will already cut manual steps and errors. For operations that do pick, pack, and kit spares, technologies such as pick-to-light and voice-directed picking reduce walking and searching. Robotics Tomorrow estimates that order picking represents about half of warehouse operating costs; even small gains here convert directly into faster ship times. Slotting the most common RA spares near packing stations and pre-building critical repair kits helps the shipping clock start early. At the dock, consistent labeling, dimensioning, and documentation turn handoffs into minutes instead of hours and reduce the chance of a miss-sorted box that disappears into a conveyor canyon.

On the transport side, Leverage AI highlights that congestion costs American shippers tens of billions of dollars each year and consumes over a billion hours, with notable per-truck costs. That reality makes dynamic route planning a practical lever, not a theoretical one. Entourage Freight Solutions emphasizes the value of an expert expedited partner with broad coverage and real-time visibility, and their perspective squares with what works at three in the morning: share exact shipment details, agree decision rules for reroutes, and keep everyone on the same status feed so you can coordinate plant resources to meet the truck the minute it arrives. Robopac USA’s packaging guidance reminds us that end-of-line packaging decisions upstream of shipping can reduce damage and rework. In MRO spares this is easy to overlook. Stabilizing loads, protecting sensitive electronics, and labeling for environmental handling avoid the worst outcome of an expedited shipment, which is a fast arrival with damaged goods.

How to Decide What to Expedite and How

If everything is urgent, nothing is urgent. A structured decision approach makes expediting faster and safer because it clarifies the why and how.

| Trigger | Immediate Action | Why It Saves Time | Control Risk to Manage |

|---|---|---|---|

| Line-down on a critical cell | Classify component criticality; initiate dual-path sourcing and logistics | Parallel paths compress decision time and transit time | Firmware and configuration mismatch |

| Planned cutover approaching with late parts | Resequence installation; pre-stage alternates; confirm supplier build plan | Resequencing keeps trades moving and aligns deliveries with work | Scope creep and undocumented changes |

| Obsolescence discovered in commissioning | Activate engineering-approved alternates; validate documentation | Eliminates redesign cycles during installation | Compliance and safety equivalence |

| Supplier slippage on a promise date | Escalate per contract; open alternate path; adjust route | Escalation plus route shift preserves target arrival | Quality and counterfeit screening |

| High-value shipment during severe weather | Pre-clear reroute; choose dedicated hot shot; move will-call | Avoids hub delays with controlled path | Driver and chain-of-custody verification |

The table reads like common sense, but it enforces a useful discipline. Each trigger has a first move. Each first move has a time-saving purpose. Each time-saver introduces a risk that must be managed explicitly. Current SCM’s focus on documented communication and ownership also belongs in this decision loop. When everyone knows who is responsible for expediting steps and which records must be updated, you do not lose hours to ambiguity.

The Metrics That Keep Expediting Honest

Metrics keep emotions in check during urgent work. On-Time Delivery and On-Time In-Full provide the basic view of supplier performance and real arrival. Expediting lead time, defined as the span from first escalation to confirmed delivery, tells you whether your process is actually accelerating outcomes or simply creating noise. Supplier responsiveness, quality compliance, and communication rate fill out the picture for partner selection. Leverage AI advocates building thresholds and alerts for these metrics in a control tower so exceptions are visible rather than buried in inboxes.

Inside the plant, measure time to install, time to configure, and time to safe restart. Those are the intervals that matter to operations. Robotics Tomorrow’s observation about the cost share of picking suggests tracking internal picking time for spares as well; a practical way to improve it is to pre-kit critical assemblies and to refresh those kits during normal hours so that the expedited case is always reaching for a ready package, not chasing components across a storeroom.

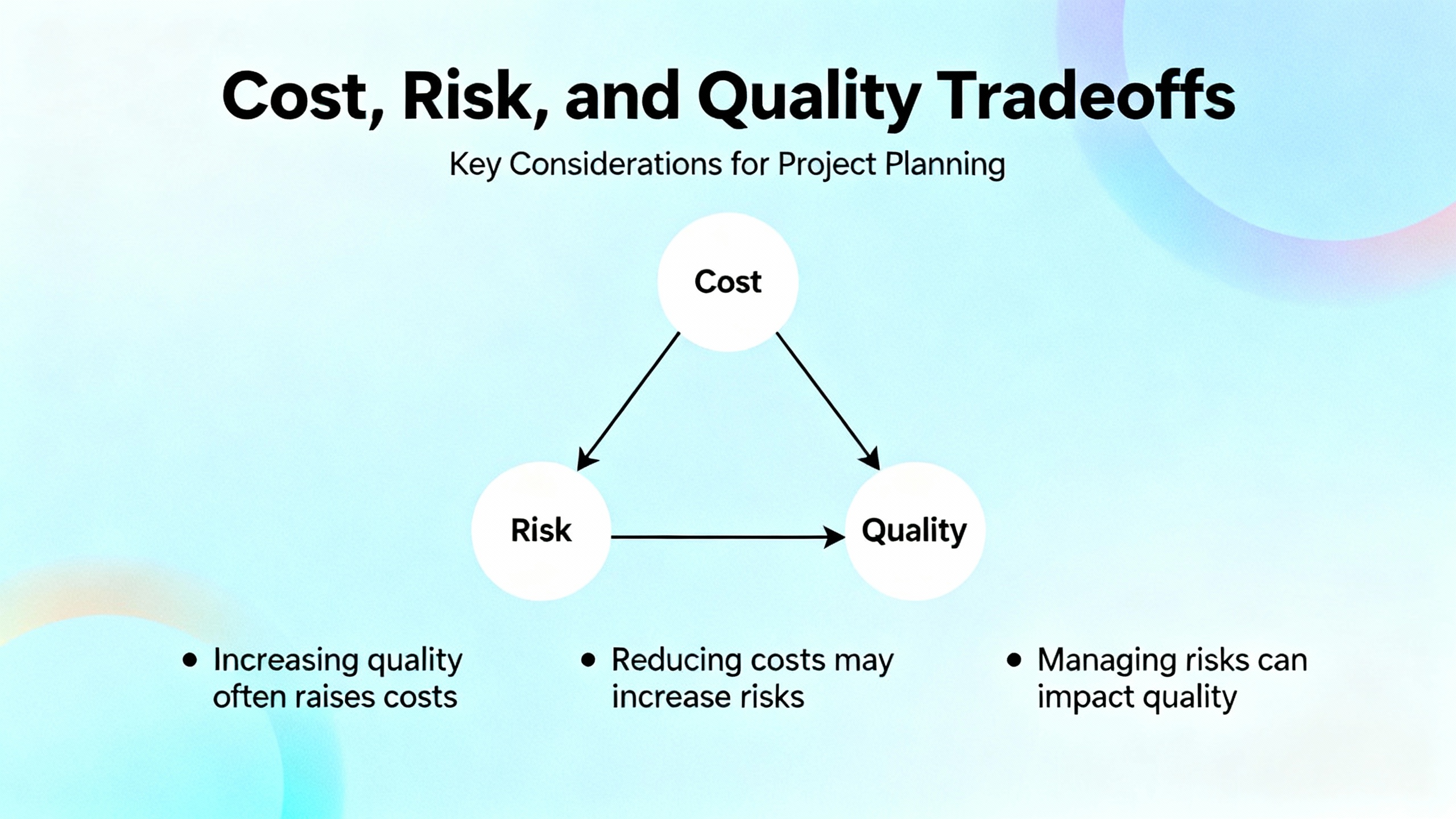

Cost, Risk, and Quality Tradeoffs You Should Acknowledge Upfront

Expediting pays back when the cost of downtime exceeds the total premium for speed. It also pays back when you avoid second-order costs that appear later. The Intelligent Document Processing literature cited by Leverage AI reminds us of the one–ten–one hundred rule where the cost to fix a problem grows steeply the later you catch it. In parts expediting, this means a wrong item caught at purchase order validation costs very little, while the same error caught at the control panel can cost rework time, quality checks, and in some cases a missed shipment to your own customer. That is why real expediting invests as much energy in clean data and documentation as in trucks and airplanes.

The primary risks are predictable. Premium freight costs can outpace the downtime benefit if you do not calculate them honestly. Quality risks increase when you vary from authorized channels or when you mix firmware revisions without a plan to align them. Team fatigue is real when expediting turns into a lifestyle; a disciplined program sets rules that prevent the last-minute rush from becoming the standard. The answer is not to avoid expediting. The answer is to make it rare, precise, and disciplined so that when you do it, it works.

Compliance, Traceability, and Safety for RA Components

Controls work is safety work, even when it is urgent. Maintain document control from requisition through installation. Capture serial numbers, firmware revisions, and configuration files. Keep proof of delivery and chain-of-custody materials in the same record as engineering approvals and management-of-change artifacts. Electronic proof of delivery, document automation, and centralized content management, as highlighted by SMRTR and Leverage AI, reduce the chance that a missing paper forces you to repeat work or delay a restart.

Do not bypass safety validations in the name of speed. For safety-rated components, even functionally similar replacements require equivalence verification and a documented approval path. For programmable devices, keep version control close. Aligning firmware and project files during installation removes a frequent source of late-stage delay. This is one of those moments when a two-hour configuration and validation window saves you a full shift of downtime the next day.

A Service Pattern That Works When the Stakes Are High

The service model I recommend, and have used, has a few constant characteristics. There is a clear triage process staffed by people who understand both the plant and the supply market, with authority to escalate. The supplier network is pre-qualified and actively scored so that when an emergency hits you do not start calling an unknown list; you start at the top of a ranked, reciprocal relationship list. The ERP and purchasing workflows are integrated with a control tower view that standardizes item validation, exceptions, and audit trails. Logistics choices are decision rules rather than ad-hoc preferences, so the right mode is selected on facts. Installation support is part of the promise, not an afterthought, which means a plan exists for configuration, validation, and documentation before the box arrives. Finally, a post-incident review updates the playbook, because every expedite is a chance to remove a future expedite.

Practical Moves You Can Make This Week

You can improve speed in days without buying a robot or an AI platform. Start by identifying the top ten RA component SKUs that have stopped a line in the past twelve months and verify that each has a documented, approved alternate and a verified supplier path. Confirm that your purchase order system validates item numbers, quantities, and terms before the order leaves your building; this one change removes a surprising number of rework hours. Create a single-source status page, even a simple shared dashboard, where supplier promises, tracking numbers, and next updates live; the time you save by eliminating status emails is yours to redirect toward the actual work. Walk your storeroom and confirm that labeling, slotting, and kitting for those same top SKUs support a sixty-second pick-to-pack; small changes in where items live make measurable differences in urgent moments. Agree a route escalation with your logistics partner for weather or hub disruptions so no one has to invent an answer when conditions change.

Short FAQ

How do I know when to accept a refurbished or reconditioned component for a fast repair? The decision belongs to risk management and quality as much as procurement. If the part is not safety-rated, if you have provenance and test documentation, and if the downtime cost exceeds the value at risk, refurbished can be acceptable as a short-term bridge. Ensure you capture serials, perform an incoming functional test, and plan a later swap to new stock if policy requires it.

Can I cross-ship a controller or drive with a different revision and sort it out during install? You can, but only with a plan. Align firmware and application files before installation, verify compatibility notes from the manufacturer, and perform a controlled validation before returning to production. The time saved by earlier delivery evaporates if you add hours during commissioning because the files do not match the hardware.

What is the single best metric to improve if I want to get faster? The most leverage usually comes from improving expediting lead time, the interval from the moment you flag a risk to the moment the shipment is confirmed for delivery. Most of that time is under your control because it lives in exceptions, approvals, and communication. Tighten those loops and transit time becomes the only clock that matters.

Reference KPIs and Ownership

A concise view of what to track and who should own it helps you sustain improvements. The owner field does not delegate accountability; it clarifies who collects the data and drives the improvement loop.

| KPI | Definition | Primary Owner |

|---|---|---|

| On-Time Delivery (OTD) | Percent of orders delivered on or before the confirmed date | Procurement |

| On-Time In-Full (OTIF) | Percent of orders delivered on time with complete and correct quantity | Procurement |

| Expediting Lead Time | Time from escalation to confirmed delivery | Supply Chain |

| Supplier Response Time | Time from inquiry to actionable confirmation | Procurement |

| Quality Compliance | Percent of expedited items passing incoming inspection | Quality |

| Install-to-Restart | Time from receipt to safe production restart | Controls/Operations |

Selected Sources Cited

The following sources inform the practices described here and offer deeper reading for teams building or refining expedited parts programs.

| Publisher | Focus |

|---|---|

| Bizmasterz | Production expediting definitions, value, and process control |

| Current SCM | Expediting discipline, roles, and communication practices |

| Leverage AI | AI levers for supply chain delays, control tower concepts, OTIF and IDP |

| Oracle NetSuite | Warehouse automation technologies and process foundations |

| Robotics Tomorrow | Picking cost drivers and automation considerations |

| The Interline | Logistics automation trends and network design reality checks |

| Entourage Freight Solutions | Practical expedited logistics strategies and safety |

| Robopac USA | End-of-line packaging and shipping reliability |

| SC Solutions | Shipping process discipline to prevent delays |

| SMRTR | Real-time tracking, route optimization, and compliance |

| Vecna Robotics | Logistics optimization, AMRs, and analytics-enabled operations |

| Shipfusion | Shipping speed optimization, KPIs, and customer impact |

Closing

When a plant is down you do not need magic; you need a method. The shortest path to a safe restart with Rockwell Automation components is a disciplined expediting model that treats data, suppliers, logistics, and installation with equal seriousness. Build the playbooks now, measure what matters, and rehearse the handoffs. When the call comes at 3:00 AM, you will be the partner everyone is relieved to have on the other end of the line.

References

- https://www.entouragefreightsolutions.com/six-strategies-for-getting-the-most-out-of-your-expedited-logistics

- https://www.assemblymag.com/articles/94746-increasing-lead-times-for-automation-components-become-an-issue-for-systems-integrators

- https://bizmasterz.com/how-is-expediting-used-in-production-management/

- https://www.burqup.com/blogs/delivery-automation-last-mile-efficiency

- https://robopacusa.com/ways-to-speed-up-your-manufacturing-shipping-process/

- https://www.roundtrip.ai/articles/strategies-improve-delivery-speed

- https://scsolutionsinc.com/streamlining-the-shipping-process-for-faster-deliveries/

- https://www.shipfusion.com/blog/shipping-speed-optimization

- https://blog.tryleverage.ai/blog/7-ways-ai-automation-reduces-supply-chain-delays

- https://calibo.com/blog/increase-engineering-delivery-velocity/

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment