-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

End of Life GE Fanuc Parts: EOL Component Solutions

As a systems integrator who has lived through more than a few midnight changeovers, I’ll be direct: end‑of‑life on GE Fanuc hardware is not a reason to panic; it’s a reason to plan with discipline. The right mix of lifecycle visibility, parts strategy, and migration know‑how keeps plants running while budgets stay under control. This article explains what EOL really means for GE Fanuc users, how to decide between repair and replacement, which migration paths work in practice, and how to buy and care for legacy parts without getting burned. I’ll ground the guidance in proven practices and credible industry commentary from AH Group, CIMTEC Automation, Cybertech Automation, Industrial Automation Co., Do Supply, Altium, Component Dynamics, VSE, Maple Systems, and others.

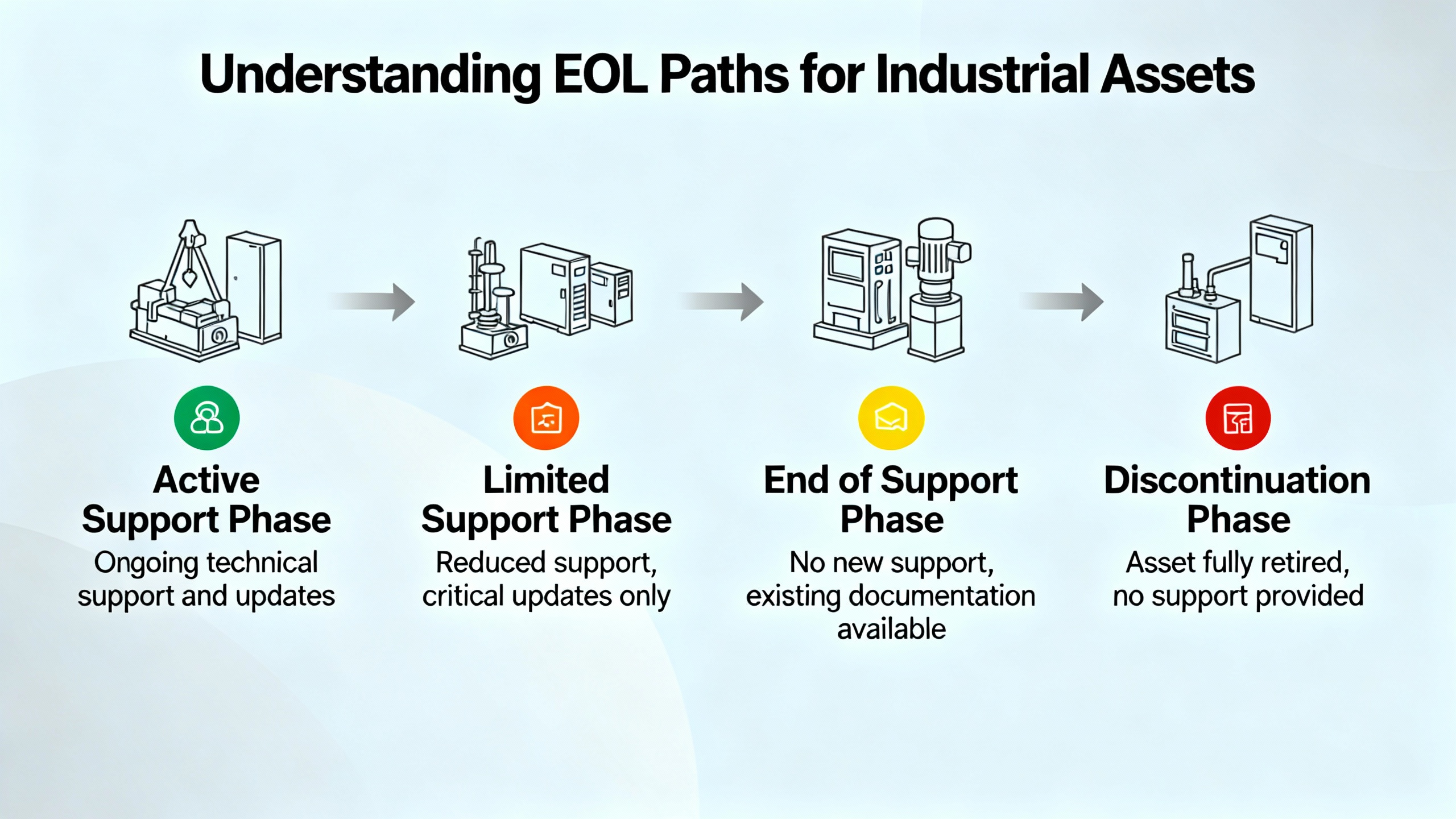

What EOL Really Means for GE Fanuc Hardware

End of life, in practical terms, is the point when an original supplier stops building or supporting a component or system. Obsolescence often arrives before that when a part stops fitting with current technology, materials, or standards. The result is tighter supply, longer lead times, and rising prices. In the PLC world, that arc is familiar: active production, mature support, EOL, and finally obsolete status where spares come from the secondary market or repair houses. Industrial Automation Co. notes that many U.S. plants still run controllers that are 15 to 30 years old—names like GE Fanuc 90‑30 and 90‑70 are common on production lines—because they were robust and operators know them well.

The risks are equally familiar. Scarce parts take longer to find and cost more—legacy modules can run two to three times their original list price. Security patches stop arriving, so risk grows quietly. The skilled labor pool shrinks. And the math gets real in a hurry: if downtime runs at $10,000.00 per hour, waiting five days for a rare CPU costs about $1,200,000.00 in lost production, before overtime and penalties are counted. The broader picture aligns with AH Group’s view across manufacturing sectors: obsolescence increases production delays, quality and compliance risk, and total cost unless it’s managed proactively.

The Business Impact of Component Obsolescence

From a plant manager’s perspective, obsolescence is a cost‑avoidance problem masked as a supply challenge. It drives premium broker pricing, forces redesigns on a schedule you didn’t choose, and tempts teams into questionable sources when the line is down. Altium’s guidance from aerospace electronics applies broadly: procurement and engineering must work together to forecast lifecycles, pre‑buy critical spares, and verify distributor legitimacy to avoid counterfeits. Regulations also nudge behavior; for example, lead‑free transitions and RoHS constraints have pushed manufacturers to discontinue legacy variants, accelerating EOL for “leaded” configurations. Even if your factory floor does not have aerospace constraints, these material and standards shifts ripple through industrial catalogs and into your BOM.

When obsolescence is treated as a managed, ongoing risk—rather than a surprise—it gets cheaper. AH Group emphasizes building a plan, integrating EOL monitoring into engineering workflows, and partnering with suppliers for early notice of last‑time buys. Component Dynamics adds organizational muscle: appoint a clear owner, keep the BOM current with lifecycle data, and refresh designs deliberately so you reduce the frequency and severity of future EOL events. VSE’s perspective from contract manufacturing rounds it out: a disciplined component engineering function tracks lifecycle status and executes pin‑compatible substitutions or redesigns early, before stockouts force emergency changes.

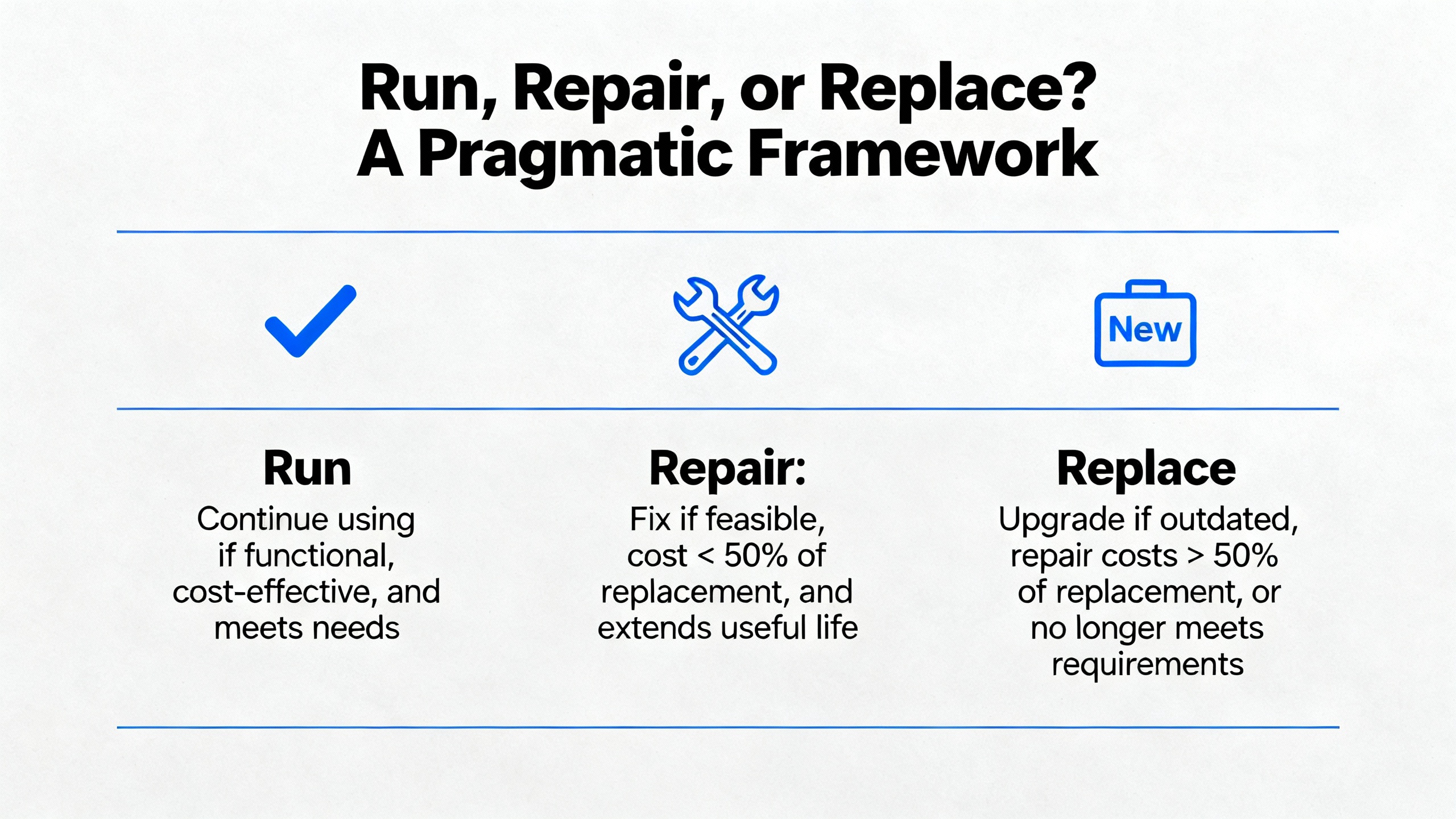

Run, Repair, or Replace? A Pragmatic Framework

Most GE Fanuc users don’t need a rip‑and‑replace tomorrow. A practical rule of thumb from Industrial Automation Co. is to run a legacy system as long as spares are predictable and mean time between failures isn’t eroding. Repairs make sense when the asset is non‑critical or redundant, when you can secure warranty‑backed repair and tested spares, or when you need a bridge while capital is approved. Replacement becomes the rational choice when repeated failures create unpredictable downtime, when the asset is mission‑critical or safety‑critical, or when repair costs approach or exceed the value of an upgrade—especially if a broader modernization is underway for networking, data visibility, or safety.

Do Supply highlights practical benefits of modern platforms that matter in the business case: higher processing headroom, better redundancy, security patching, native compatibility with current IT/OT architectures, centralized diagnostics, and online‑replaceable hardware. The operational results are measurable in throughput, quality, and energy use, so total cost of ownership moves in your favor while risk retreats.

| Option | When It Fits | Core Advantages | Core Tradeoffs |

|---|---|---|---|

| Run with tested spares | MTBF stable, spares predictable | Lowest capital outlay; zero change risk | Future exposure grows; skills and tools age out |

| Repair/refurbish | Non‑critical assets; bridge strategy | Warranty‑backed repairs; fast turnaround possible | Diminishing returns if failures increase |

| Service exchange | Immediate need; known module | Quick swap; cost lower than new | Availability varies; verify test rigor |

| Replace/migrate | Repeated failures; modernization goals | Reliability, security, integration, diagnostics | Capex, validation effort, outage planning |

EOL Paths for Common GE Fanuc Assets

Legacy GE Fanuc comes in flavors, and each has a sensible path forward.

The GE Fanuc 90‑30 often migrates cleanly to Emerson’s RX3i family, which is frequently the most compatible successor cited by practitioners, including insights shared by Gani Graceni on LinkedIn. This path preserves much of the existing mental model and can reuse wiring with appropriate adapters or new bases. Where cross‑brand migration is preferred, Allen‑Bradley or Siemens are viable choices, but they require careful re‑mapping of I/O and a rigorous logic conversion strategy.

For GE Fanuc 90‑70 and especially 90/70 GMR safety PLCs, specialty expertise goes a long way. Cybertech Automation describes database‑driven extraction of Logicmaster logic, Genius configurations, and GMR datasets to rebuild applications on modern safety platforms while validating initiator‑to‑final‑element behavior, cause‑and‑effect matrices, ranges, scaling, and trip logic. That approach improves traceability through FAT and SAT while cutting engineering time and re‑test effort. For safety systems, plan commissioning with TÜV‑qualified methods; companies with deep credentials in IEC 61511 migrations exist and are worth involving early.

Series Six still shows up on plant tours. CIMTEC Automation has supported GE lines since the mid‑1980s and frames migration sensibly: perform a comprehensive assessment of installed hardware and the logic program, quantify the rungs, flag instructions that won’t translate, reconcile I/O maps, and plan renames where software rules changed. The converted program is then proofread, edited, tested on target hardware, and deployed on a schedule that respects your downtime windows. This is not a one‑size‑fits‑all effort; some conversions take a few hours and others run to weeks depending on program size and complexity.

Operator interfaces deserve their own plan. Maple Systems offers HMI hardware and software replacements for GE Intelligent Platforms, Fanuc CNC series, and Emerson Machine Automation Solutions, with compatibility that spans RX3i and common Fanuc 0i and 3x/35i CNC protocols. Replacing an aging HMI while retaining the PLC or CNC can restore visibility and usability quickly, without touching proven control logic.

| Legacy Asset | Typical Path | Notes |

|---|---|---|

| GE Fanuc 90‑30 PLC | Emerson RX3i; or cross‑brand migration | Validate I/O reuse; gateways for Modbus/Profibus as needed |

| GE Fanuc 90‑70 and 90/70 GMR safety | Modern SIL 2+ safety PLC with automated extraction/validation | Preserve cause‑and‑effect; formal FAT/SAT and safety reviews |

| Series Six | Planned migration after thorough program and I/O assessment | Expect manual edits and tag renaming; staged cutover |

| HMIs and panels | Maple Systems HMI replacements compatible with GE/Fanuc/Emerson | Confirm protocol support; bench‑test screens and alarms |

Practical Spare‑Parts Strategy for Legacy GE Fanuc

A spare‑parts program is the cheapest insurance you can buy against six‑figure downtime. Start with a targeted audit of five to ten high‑risk parts that can stop production—PLCs, power supplies, CPUs, specialty I/O, network modules, legacy HMIs, and proprietary cards. Label and organize each spare, record its exact storage location, and log part numbers, supported machine, purchase date, warranty status, and the last time it was powered and tested. Industrial Automation Co. recommends staging tested spares and protocol gateways, and validating complete program backups with comments and I/O maps; that last point is critical, because a missing comment set or mis‑aligned I/O map can add hours to a restart.

Work with suppliers who verify, test, and stand behind what they ship. Some resellers publish two‑year repair warranties and offer same‑day shipping; those policies are worth paying for when the line is cold. Service exchange programs reduce time‑to‑restore by letting you receive a tested replacement while returning your failed unit, often at a lower price than buying new. If you’re buying GE Fanuc parts, providing the exact part number format ensures you get a compatible unit rather than an almost‑right variant that doesn’t seat or address correctly. When budgets are tight, begin with one spare per true single‑point‑of‑failure area and expand coverage over time as risk declines.

| Sourcing Mode | What It Means | When to Use | Caveats |

|---|---|---|---|

| OEM‑new or new‑old‑stock | Factory build or unused legacy stock | Highest criticality; long‑term spares | Price premium; limited availability |

| Refurbished/tested | Rebuilt and verified on test rigs | Balanced cost and speed | Inspect test documentation and warranty |

| Service exchange | Swap failed unit for a tested one | Emergency restorations; budget‑friendly | Core return terms; compatibility checks |

| Third‑party equivalent | Functionally compatible replacement | Non‑safety‑critical, cost‑driven | Validate specs, environmental ratings, certifications |

| Repair | Restore failed unit to service | Bridge to migration; low capital | Turn time varies; watch for repeat failures |

Engineering for Fewer Surprises: Proactive Obsolescence Management

The most effective way to control EOL cost is to see it coming. AH Group recommends keeping a lifecycle analysis for critical components, defining escalation paths, and setting communication protocols so responses are fast and confident. Digitally, integrate EOL status into your PLM and engineering tools so part changes trigger alerts inside the design workflow rather than after a buyer is already shopping the secondary market. Supplier partnerships matter; aligning roadmaps, negotiating last‑time buys, and stockpiling correctly sized buffers avoids paying panic premiums later.

Designing for flexibility is a powerful hedge. Standardize interfaces, allow alternate ranges where safe and practical, and modularize subsystems to simplify future swaps. Cross‑functional reviews—quarterly is a sensible cadence—help catch regulatory changes and market shifts that trigger obsolescence. Altium’s guidance underscores the value of a centralized digital BOM with lifecycle status and supplier data so teams can qualify alternates sooner. Component Dynamics takes a similar stance and adds ownership and cadence: assign an obsolescence manager, keep the BOM current, and use predictive analytics and market research to flag parts at risk before they get pulled.

Migration Planning That Respects Production

CIMTEC Automation’s approach reflects how migrations succeed in real plants: start by inventorying the installed base and gathering the current PLC program. Have a specialist review the code to identify rungs that won’t convert cleanly, quantify the scope, and confirm that rung comments and tag names meet the current tool’s naming rules. Evaluate which modules can stay, which need firmware or chip updates, and which must be replaced; then estimate manual intervention for I/O map changes. Only after that homework should you convert the program, proofread it, procure hardware, and test on the target platform. Depending on program length, the initial review can run a few hours to a few weeks, so sequence work against planned downtime windows and plant priorities.

Cybertech Automation’s safety migrations complement that narrative for 90/70 GMR users. Automated extraction from Logicmaster projects, Genius blocks, and GMR datasets feeds a project database that drives configuration, documentation, gateways, graphics, alarms, and tests. That automation supports thorough FAT and SAT while improving quality and easing change management. Where shut‑downs are rare or expensive, online upgrades and automated validation reduce risk, though they demand discipline in planning and contingency design.

Across vendors, a consistent migration pattern keeps risk low: back up everything, including comments and I/O maps; document serial and fieldbus protocols (RS‑232/485, Modbus, Profibus); build a bench test with simulated I/O; validate communications to HMIs, drives, and supervisory systems; stage the cutover during low‑risk windows; and maintain a rollback plan with verified backups. When the target platform is RX3i, conversion utilities and in‑family know‑how can shorten timelines. When switching brands, plan time for logic translation or rewrites and for panel rework if new hardware footprints require it.

HMI Replacement Without a PLC Rip‑and‑Replace

Replacing an aging HMI often delivers a fast win. Maple Systems positions HMI hardware and software that speaks to GE Intelligent Platforms, Fanuc CNC series, and Emerson machine automation systems, along with a wide range of other PLCs. In practice, that means you can refresh operator panels, improve usability, and restore spare availability without touching the control logic that is running your machines. The keys are protocol verification, careful screen and alarm translation, and a short bench test to prove tag mapping and comms before you power down the line.

Quality, Counterfeits, and Compliance

As legacy parts move to the secondary market, verification gets more important. Altium warns that unauthorized channels increase counterfeit risk, and recommends tight collaboration between procurement and engineering to avoid surprises. For specialized contexts like aerospace, leaded versus lead‑free materials can create hard constraints; while many factory applications are less restrictive, RoHS‑driven discontinuations still ripple through downstream industries, so it is smart to validate material compatibility and certification early.

On safety projects, lean on qualified methods and people. Cybertech Automation notes extensive safety credentials in its work, and the general lesson is transferable: plan migration and validation against recognized standards, document cause‑and‑effect, and treat FAT/SAT as non‑negotiable. When lives and licenses are on the line, shortcuts are expensive.

Care and Storage Tips for GE Fanuc Spares

Even the best spare is a liability if you can’t find it or it won’t boot. Store PLCs, power supplies, I/O, and HMIs in clean, dry conditions with ESD protection and proper labeling. Power and test high‑value spares periodically to catch latent defects before a crisis. Stage a small set of protocol gateways for common fieldbuses so you can bridge older networks during phased upgrades. Keep firmware, programming tools, licenses, and dongles imaged and documented, and retain offline copies of programs with comments and accurate I/O maps; Industrial Automation Co. calls out this specific point because it is the difference between a one‑hour swap and an all‑day hunt.

From a sustainability angle, remember that electronics do not last forever on the shelf. Global e‑waste exceeds roughly 55 million tons each year with only about 12.5% properly recycled, and heavy‑metal contamination can exceed safety thresholds dramatically in dumping hotspots. Those are reminders to manage the full asset lifecycle responsibly, not reasons to hoard indefensibly.

Costing It Out and Building the Business Case

You don’t need perfect numbers to make a sound decision; you need a consistent way to count. Industrial Automation Co. frames downtime cost in four buckets: lost production value, labor costs and overtime, rush shipping and emergency sourcing premiums, and reputation or contractual penalties. A simple model—units per hour multiplied by margin, multiplied by expected downtime—offers an anchor. Against that, compare the investment for a migration, the reduction in risk and variability, and the operational benefits cited by Do Supply: fewer failures, better diagnostics, redundancy, easier maintenance, and improved integration with analytics or energy management. When migrations are phased and scheduled during planned outages, the payback often lands faster than expected because you avoid a few five‑digit emergencies.

Takeaway

Treat GE Fanuc EOL as a manageable engineering and supply‑chain challenge, not a fire drill. Build lifecycle visibility into your BOM and workflows. Stock a small, well‑managed set of tested spares with verified backups. Choose repairs and service exchanges as bridges when they make sense, and plan migrations deliberately to modern platforms that restore reliability, security, and spare availability. Use vendor tools and specialist methods—especially for safety systems—to reduce risk, improve traceability, and protect production. The plants that navigate EOL well combine early detection, flexible design, disciplined sourcing, and a pragmatic migration playbook.

FAQ

Q: How long can I keep running a GE Fanuc 90‑30 or 90‑70 after EOL? A: There is no single expiration date. Many facilities run 10 to 20 years past EOL if environments are reasonable and spares are available. Risk and surprise costs increase over time, so monitor MTBF and parts availability closely and pivot when those trends turn against you, as Industrial Automation Co. advises.

Q: Is it wise to buy used or refurbished parts from independent resellers? A: It can be, provided you verify testing, demand clear warranties, match exact part numbers, and avoid dubious channels. Altium’s procurement guidance stresses working with reputable, traceable sources to minimize counterfeit risk. Service exchange with warranty is often the fastest way to restore service at a reasonable cost.

Q: What is the most compatible migration path for a 90‑30? A: Many practitioners cite Emerson’s RX3i as the most compatible in‑family path, which simplifies logic conversion and I/O reuse. Cross‑brand moves to Allen‑Bradley or Siemens are viable but require more effort in logic translation, I/O adaptation, and validation.

Q: How do I minimize downtime during a PLC migration? A: Inventory hardware and networks, back up programs with comments and accurate I/O maps, bench‑test with simulated I/O, validate all communications to HMIs and drives, and schedule cutover during planned shutdowns. Maintain a rollback plan with verified backups. CIMTEC Automation and Cybertech Automation emphasize rigorous FAT/SAT and, for safety systems, formal cause‑and‑effect validation.

Q: Can I refresh only the HMI and keep my GE Fanuc PLC or CNC? A: Yes. Maple Systems offers HMIs compatible with GE Intelligent Platforms, Fanuc CNC series, and Emerson machine automation systems. Confirm protocol compatibility, convert screens and alarms carefully, and verify on a bench before the line goes down.

Q: What does “service exchange” mean when sourcing legacy parts? A: You receive a tested, refurbished unit immediately and send your faulty unit back as the “core.” It’s typically faster and less expensive than buying new, but you should still verify compatibility, test standards, and warranty terms.

Sources cited in this article include AH Group, CIMTEC Automation, Cybertech Automation, Industrial Automation Co., Do Supply, Altium, Component Dynamics, VSE, Maple Systems, Gani Graceni (LinkedIn), and related industry materials. Links will be provided separately in the References.

References

- https://fieldpoint.net/how-to-better-manage-the-industrial-equipment-product-lifecycle/

- https://www.plctalk.net/forums/threads/help-transitioning-from-series-1-ge-fanuc-to-more-modern-plc.146582/

- https://dynamictech.solutions/4-best-practices-effective-product-end-of-life-management

- https://www.gefanuc-spares.com/fanuc-parts.htm

- https://ahgroupna.com/navigating-component-obsolescence-strategies-for-modern-manufacturers/

- https://resources.altium.com/p/component-obsolescence-aerospace-electronics-best-practices

- https://cimtecautomation.com/migrating-from-older-ge-plcs/

- https://www.component-dynamics.com/6-best-practices-for-obsolescence-management/

- https://www.linkedin.com/pulse/dealing-obsolete-ge-fanuc-90-30-plc-challenges-gani-graceni-ui9lc

- https://maplesystems.com/ge-fanuc-hmi-alternative/?srsltid=AfmBOorCIxnG0VzXact3ZnSGPFQ_ewtUkzBXuL1acKJN8H5scoBp1ZMa

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment