-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Same Day Allen‑Bradley Module Shipping: Express Rockwell Automation Parts

When a Rockwell Automation cell goes down, the clock does not tick in minutes; it ticks in dollars. I have lived that reality on plant floors for more than twenty years, commissioning lines at 3:00 AM, chasing intermittent faults in distributed I/O, and hunting a ControlLogix I/O card while operators stare at an idle conveyor. In those moments, “same day” is not a marketing line. It is a commitment to precise identification, flawless handoff, and a logistics playbook that gets the exact Allen‑Bradley part from shelf to panel fast, safely, and fully accountable.

This guide is the pragmatic, field‑tested approach I use to execute urgent replacements for PLC modules, PanelView terminals, drives components, and other Rockwell spares. It blends hands‑on experience with proven logistics practices highlighted by sources such as ShipERP, BOCSIT, C.H. Robinson, SmartRoutes, GoUSPack, Reliable Couriers, SameDayDelivery.com, and others. The goal is simple: restore production the same day without creating new risks in the process.

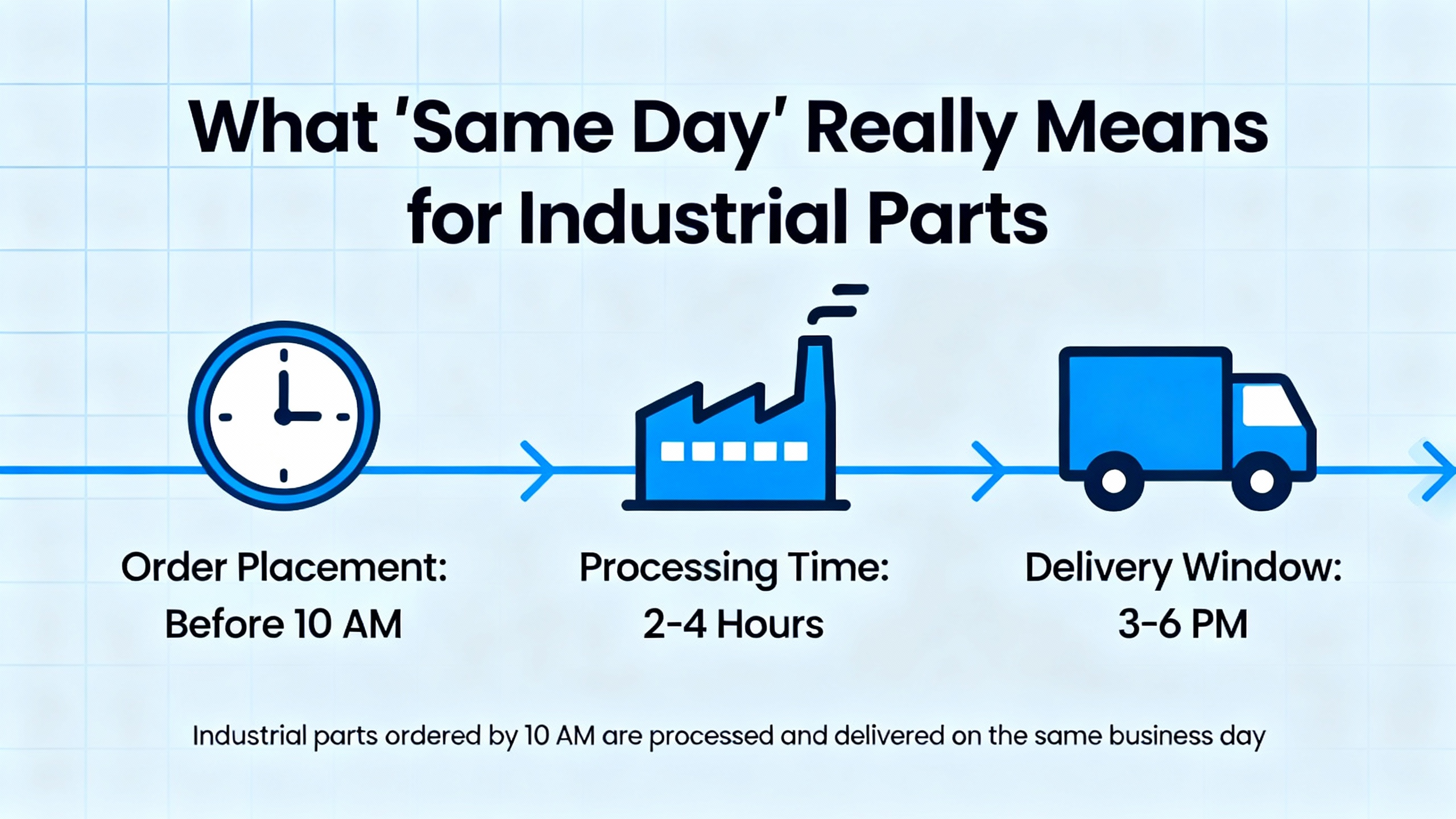

What “Same Day” Really Means for Industrial Parts

In manufacturing, same‑day is a tailored logistics service combining immediate pickup, the right vehicle or air leg, and orchestrated handoffs to meet a same‑calendar‑day delivery promise. It is not the parcel world’s one‑size‑fits‑all channel. Same‑day providers align cargo specifics—size, weight, sensitivity, and regulatory constraints—to a route that can hold time windows down to minutes. Industry partners described by GoUSPack position final‑mile precision with tight delivery windows and on‑time performance figures that approach the high nineties, enabled by trained handlers, load control, and electronic proof‑of‑delivery.

The value is not abstract. BOCSIT’s same‑day courier insights document a replacement component moving roughly 200 miles in about four hours to avert an estimated $1,200,000.00 loss, and a 2‑ton gear—approximately 4,000 lb—delivered in under eighteen hours that avoided several days of downtime and saved more than $5,000,000.00. These are not Allen‑Bradley‑specific stories, but the economics translate directly to a line‑down control module. When the cost of delay dwarfs the premium for expedite, same‑day is a strategic tool, not an impulse buy.

When to Pull the Trigger on Same Day for Rockwell Parts

Deciding to expedite should be disciplined, not emotional. Inbound Logistics recommends treating expedite as a planned lever with a clear cost‑of‑delay lens. If lost throughput or missed customer commitments exceed the expedite premium, the decision is straightforward. The timing of the request matters, because minutes can shift capacity and cost. Where practical, use partial expediting: ship the single most critical card or HMI overnight or same‑day and move the balance by standard service to contain spend.

A second trigger is systemic risk. If you are running lean on critical spares or operating JIT, the exposure window is wider. BOCSIT notes that same‑day services support lean inventory and agile schedule changes. If your backlog, penalty clauses, or seasonal commitments mean a day’s loss cascades into weeks, escalate logistics accordingly.

Getting the Part Right the First Time

Same‑day is unforgiving of guesswork. The fastest truck in the state cannot fix a mispicked catalog number. DO Supply emphasizes verifying the exact part number and compatibility up front, which is doubly true for Allen‑Bradley modules that often have closely related variants. In parallel, take a cue from Creative Automation’s best practice of unique Custom Part IDs. While that program is specific to their parts, the lesson generalizes: precise identifiers collapse phone calls, eliminate ambiguity, and cut error risk. Keeping each machine’s critical part identifiers at your fingertips turns a frantic morning into a five‑minute order.

When I run a line‑down replacement, the first conversation with procurement or the supplier confirms the full identifier and the use context. This includes catalog number, revision or series notation if applicable, the quantity actually needed to restore function, and any configuration or accessory dependencies such as terminal bases or communication adaptors. I also provide weight and rough dimensions for logistics planning, the pickup and delivery site constraints, and whether the destination lacks a dock and requires a liftgate. If the shipment contains anything regulated or temperature‑sensitive—batteries embedded in a terminal, adhesives associated with a kit, or components susceptible to ESD—call it out immediately to avoid disqualifying a carrier late in the process. BOCSIT’s packaging notes are unambiguous about how special handling and labeling are triggered by those details.

Logistics Options That Actually Hit Same‑Day

Same‑day is not a single mode. The right method depends on distance, size, and risk tolerance. BOCSIT outlines fleets from small cars and motorcycles to vans and box trucks, plus temperature‑controlled equipment for sensitive electronics. SameDayDelivery.com and GoUSPack describe scaling from compact vehicles to straight trucks and tractor‑trailers when the cargo demands it. ShipERP’s guidance makes it clear that urgent, line‑down parts sometimes justify air, while smaller components can ride LTL when you are optimizing cost rather than hours.

| Mode | Typical Use | Speed Profile | Strengths | Watchouts |

|---|---|---|---|---|

| Local same‑day ground | In‑region modules and terminals where a direct road run can make it within hours | Hours, depending on distance and traffic | Direct handoff, minimal touches, electronic proof‑of‑delivery | Limited radius, driver availability at peak times |

| Dedicated hotshot truck | Palletized or heavy parts that need a straight shot without cross‑docks | Same‑day to overnight, distance‑dependent | Single custody, predictable ETA, safe handling | Premium cost; permits for unusual dimensions |

| Next Flight Out air plus final mile | Long‑distance, truly time‑critical replacements | Same‑day across large geographies when schedules align | Fastest long‑distance option; wide coverage | Airport cutoffs, packaging standards, weather volatility |

| LTL | Non‑urgent replenishment or when consolidating components | Day‑plus; cost‑efficient not speed‑optimized | Lower spend, good for replenishment | Multiple touches, higher damage risk for fragile electronics |

| FTL | Larger consolidated moves or when avoiding LTL touches | Direct transit without cross‑docks | Control and lower damage risk | Lead time to secure equipment, higher minimum cost |

Packaging and Handling for Allen‑Bradley Modules

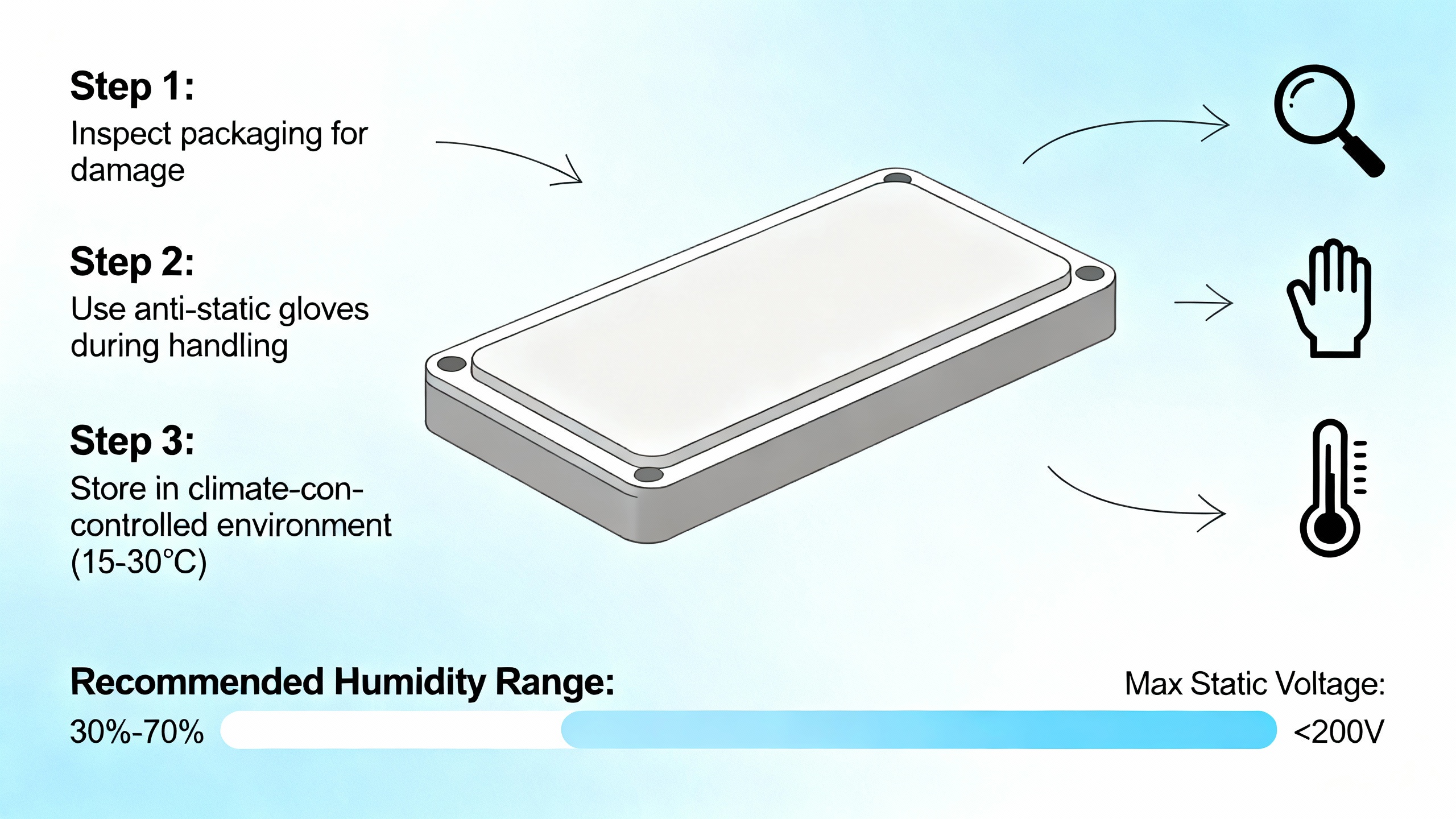

Electronics fail as often in the box as on the panel when packaging is rushed. BOCSIT’s packaging guidance translates cleanly to PLC I/O cards, communication modules, and HMIs. For small electronics, use anti‑static bags with individual cushioning and a compartmentalized outer carton so the parts cannot collide. For medium or fragile units, step up to sturdy boxes or crates with void fill, custom foam, or suspension. Consider shock indicators if the module’s failure sensitivity justifies it. Heavy or long items belong on a pallet with tight strapping and edge protection; if a crate is required, brace internally and mark the center of gravity and lifting points for safe handling.

Do not guess your way through hazardous or sensitive shipments. If a component includes a battery or requires controlled conditions, BOCSIT is plain about temperature‑controlled vehicles, proper containment, absorbents, hazard labels, and the inclusion of safety data sheets. Curri and GoUSPack both underscore the need for trained handlers, securement, and, where needed, white‑glove care to protect high‑value items and ensure safe entry and exit at sites that are not set up like a conventional dock.

Compliance Without Drama

Rushing does not excuse noncompliance; it compounds risk. ShipERP’s guidance on export formalities is succinct. Under U.S. Foreign Trade Regulations, shipments valued over $2,500.00 must be reported to the Automated Export System with an accurate Electronic Export Information filing. Their compliance enablement tools also speak to continuous monitoring and screening to prevent avoidable delays and penalties. If you are moving across borders, validate the Harmonized System code during the quote, using examples such as HS 8431.49 for certain machinery parts where appropriate to your item. Keep origin documentation and ensure insurance aligns with the declared value, because anyone who has had a damaged HMI arrive without sufficient coverage knows the pain that follows.

Visibility, Proof, and Accountability on a Fast Clock

On same‑day runs, visibility is both a comfort and a lever for intervention. GoUSPack points to barcode or milestone scans, chain of custody handoff logs, and ePOD with time‑stamped signatures and geolocation. Legacy 3PL providers like Legacy SCS emphasize live inventory and shipment portals and KPI reporting. At a higher level of orchestration, C.H. Robinson describes control towers as single sources of truth that integrate disparate systems and enable proactive management; those platforms leverage AI to accelerate decisions and keep the network aligned. Whether you run this through your own TMS or via your partner’s portal, insist on real‑time status, documented custody, and a named point of contact for escalations.

Cost, KPIs, and Continuous Improvement

Speed is not the only metric. The long‑term goal is to get faster and cheaper without adding risk. SmartRoutes reports up to a 33% reduction in delivery cost through optimized routing and lower fuel consumption. ShipERP’s analytics capabilities are designed to surface performance and predict disruptions. Legacy SCS and other specialized auto‑parts 3PLs run standard KPI sets to keep service quality on track.

I recommend tracking the same few measures every time you pull a same‑day lever, and then using the data to tune the process. Measure on‑time delivery rate to judge reliability, and order cycle time to understand where the minutes go from request to receipt. Track first‑attempt delivery rate when facilities are access‑constrained, and inventory turnover alongside backorder rate to see if your spares strategy is pushing you toward unnecessary expediting. Monitor chain‑of‑custody completeness and damage claims to verify that the packaging and carrier choices are doing their job.

| KPI | What it tells you | How to improve |

|---|---|---|

| On‑time delivery rate | Reliability of partners against commitments | Use multi‑carrier routing, keep backups, and set realistic windows |

| Order cycle time | Total delay from request to receipt | Cut approval bottlenecks, pre‑stage data, and standardize packaging |

| First‑attempt delivery rate | How often the delivery succeeds without re‑attempt | Improve site access instructions and schedule to staffed windows |

| Inventory turnover and backorder rate | Whether spares policy is driving expedites | Adjust safety stock for truly critical SKUs; forecast demand realistically |

| Damage claim rate | Packaging and handling effectiveness | Upgrade materials and securement; reduce touches; choose trained handlers |

Domestic vs. Global Sourcing: Time Horizons That Matter

Conger’s lead‑time analysis is blunt about the time penalty of long‑distance sourcing. Overseas movements can add thirty to forty days in transit, while domestic suppliers eliminate customs and tariff delays. This is the quiet reason plants keep a small set of critical Rockwell spares on hand even in lean operations. If your suppliers are distant, buy less frequently in larger batches and designate a subset as a reserve for line‑down events. When a same‑day request is unavoidable, the probability that a domestic warehouse can stage and hand off immediately is far higher than a complex international handoff.

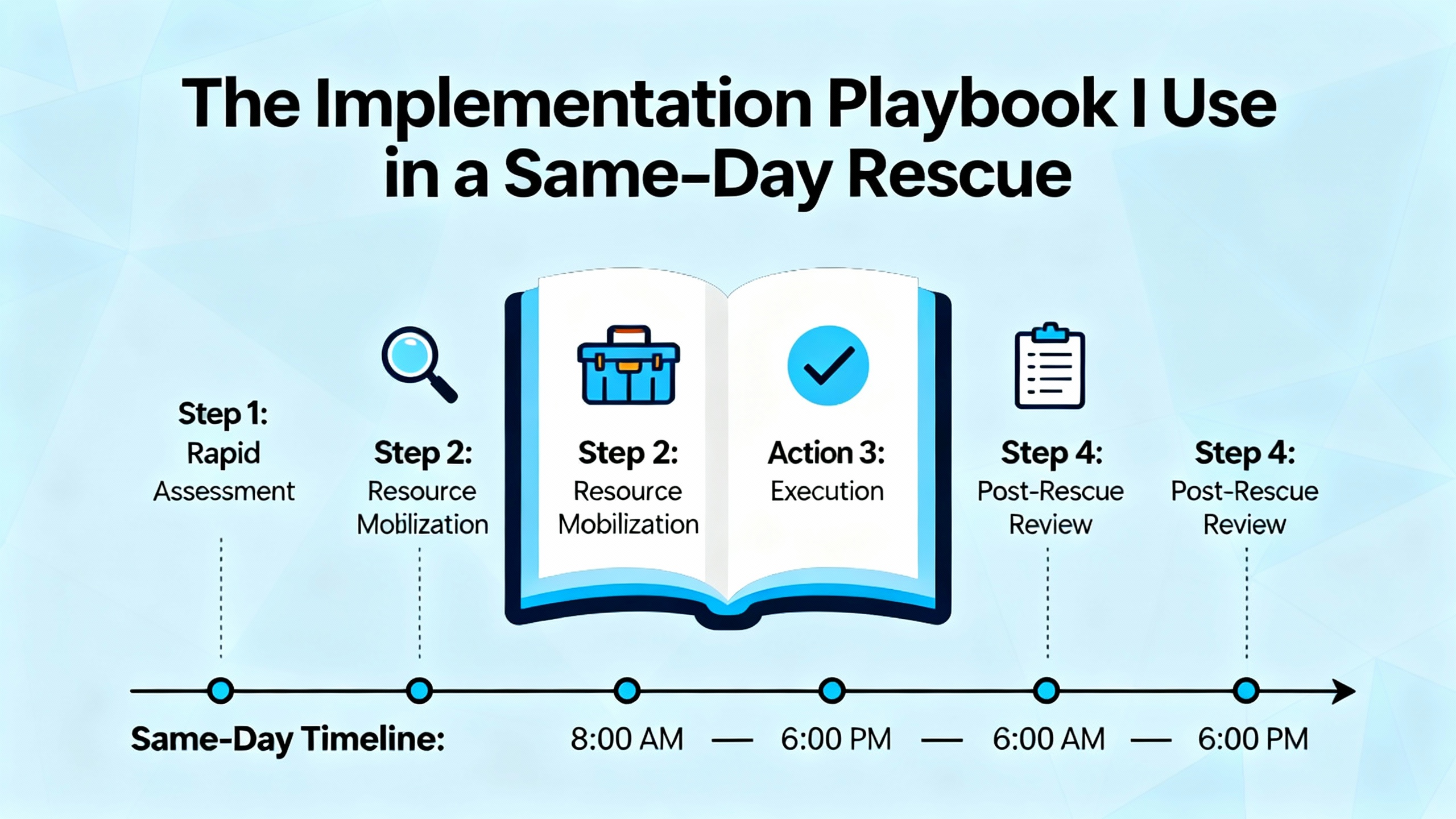

The Implementation Playbook I Use in a Same‑Day Rescue

When I get the call that a line is down and the culprit is a Rockwell module, the first move is diagnostic certainty. Closing the loop between the fault and the part narrows risk before the first phone call to a supplier. With the part confirmed, identification must be exact and unambiguous, following the DO Supply recommendation to verify the precise number and compatibility. If the site has embraced a Creative Automation‑style identifier discipline, the order itself becomes a two‑sentence interaction that prevents miscommunication.

Sourcing runs in parallel with logistics. I contact multiple suppliers to confirm stock and condition, with a bias toward new surplus or verified refurbished when downtime cost exceeds the premium. I also open the logistics lane immediately, describing size, weight, fragility, and any special constraints to align with providers such as Reliable Couriers, GoUSPack, or a vetted regional same‑day operator. For longer distances, I will ask an air‑capable expeditor about a next flight out leg and a coordinated final mile.

Packaging is not left to chance. The shipping team secures the module in an anti‑static bag with foam isolation, adds a shock indicator if it is a glass‑front terminal or fragile assembly, and locks the outer carton to a pallet if weight or size suggests risk in handling. If a site has no dock or forklift, I specify liftgate service and verify driver instructions, because the curb is not a friendly place to open an expensive HMI.

Compliance and documentation move with the shipment. If value exceeds $2,500.00 and the part is crossing borders, an AES filing is executed, guided by ShipERP practices, with HS codes validated. The carrier’s ePOD and real‑time tracking are monitored by the controls or maintenance lead responsible for restart. Before closing the loop, the receiving tech photographs the unit on arrival, and a simple bench function check is run when feasible. The module is installed only after grounding and ESD precautions are set, then the line is restarted with the quality team watching the first run back.

Pros and Cons of Same‑Day for Rockwell Parts

The advantages are straight to the point. Same‑day restores production quickly, keeps customer commitments on track, and helps you maintain lean inventory without adding chronic risk. BOCSIT’s case examples, while not Rockwell‑specific, capture the disproportionate financial impact of short‑circuiting downtime. The structured visibility that providers like GoUSPack and 3PLs such as Legacy SCS bring to the table reduces the uncertainty that typically makes managers nervous.

The downsides are equally real. Same‑day is a premium service, so the cost must be justified by avoided losses, as Inbound Logistics advises. The bigger operational risk is human: an incorrect part number or sloppy packaging turns an expensive rescue into a second failure. There are also compliance pitfalls when shipments contain hazardous materials or cross borders without proper filings, which ShipERP’s export notes address. A disciplined process solves most of these problems.

Short Scenarios That Map to Allen‑Bradley Reality

Consider a regional plant with a failed I/O module. A dedicated van picks up within the hour, the module rides in ESD‑safe packaging, and chain‑of‑custody scans provide proof for warranty or audit purposes. This is the classic same‑day run that BOCSIT describes, and it mirrors the control‑room urgency I see in real plants.

On a longer route, a hotshot truck avoids cross‑dock touches that can damage sensitive modules, a preference echoed by SameDayDelivery.com and GoUSPack. For very long distances, next flight out with a tightly coordinated final mile can deliver the same day if airport schedules align. Suppliers and 3PLs with live portals like Legacy SCS keep both teams watching the same data, and a control‑tower mindset of the sort C.H. Robinson outlines improves your odds when plans change mid‑flight.

Curri documents heavy‑equipment runs and outcomes like time savings and sales lift in a different segment, but the lesson holds: network elasticity, trained drivers, and live support cut friction in urgent deliveries. When you map those enablers onto Allen‑Bradley parts, you replicate the same reliability at a smaller scale.

Choosing Partners and Setting Them Up for Success

The best same‑day partner is experienced in industrial parts, not just parcels. BOCSIT advises looking for industry expertise, geographic reach, a diverse fleet, real‑time tracking, ePOD, adequate insurance, and responsive management. GoUSPack adds precision windows and robust chain‑of‑custody. Reliable Couriers positions nationwide coverage, trained handling for industrial materials, and temperature‑controlled options when needed.

If you outsource broadly, automotive‑capable 3PLs such as Legacy SCS and specialized fulfillment operators like Speed Commerce and Red Stag Fulfillment bring tech stacks with live tracking, WMS integration, and KPI reporting, plus processes for hazardous items and returns. The thread that ties this together is integration. ShipERP’s multi‑carrier selection and analytics reduce time to label and improve visibility; SmartRoutes reminds you that even last‑mile routing and ETA communication can trim cost and frustration. Keep a preferred‑supplier network and an approved backup for each lane. Run a pilot or network assessment, as GoUSPack recommends, to validate service levels before the crisis call arrives.

Documentation You Will Be Asked For

The paperwork for domestic same‑day shipments is blessedly light, but the data needs are not optional. You will be asked for the shipper and consignee full details, an accurate description of the goods and value for insurance purposes, and any special handling notes. If the part is hazardous or contains regulated materials, include declarations and safety data sheets up front.

For exports and for any shipment valued over $2,500.00, ShipERP’s export guidance is unambiguous about filing EEI in AES with accurate data. Having HS codes validated and origin documentation ready reduces last‑minute errors. Continuous compliance monitoring and screening, which ShipERP and related tools support, will save you from de‑risking the wrong way under pressure.

| Shipment type | Required data to prepare |

|---|---|

| Domestic, non‑hazardous | Shipper and consignee contacts; part description and exact identifier; value for insurance; site access notes and delivery window |

| Domestic, hazardous or sensitive | All of the above, plus hazard classification, labels, handling instructions, safety data sheets, and temperature requirements if applicable |

| Export over $2,500.00 | All of the above, plus HS code confirmation, AES filing with EEI under U.S. Foreign Trade Regulations, and origin documentation aligned to the destination’s rules |

Make the Cost Work for You, Not Against You

The most effective way to pay less for same‑day is to use it less often and more precisely. Inbound Logistics advises specifying realistic delivery windows instead of defaulting to “ASAP,” which usually drives price up. The same article highlights partial expediting: ship the one pallet or module that gets you running while the rest follows at a regular rate. SmartRoutes’ experience suggests that route optimization and consistent telematics can shave cost, and my experience is that pre‑staged packaging for sensitive modules eliminates time‑wasting scrambles.

The single biggest cost reducer is not glamorous. Keep a lean but adequate stock of truly critical spares at the plant and document them well. Conger’s reminder that domestic sourcing trims lead times reinforces the strategy. When the rare line‑down event still demands same‑day, the decision becomes simple and the execution is faster because your process is already built.

FAQ: Straight Answers From the Field

What if the Allen‑Bradley component includes hazardous materials or sensitive elements? Follow BOCSIT’s guidance and declare it immediately. Provide safety data sheets and request temperature‑controlled or specialized handling as needed. Letting a provider discover this at pickup risks a refusal and hours lost.

What paperwork do I need for an urgent export? ShipERP’s export recommendations are clear that any shipment valued over $2,500.00 requires an EEI filing in AES, along with correct HS classification and origin documentation. Preparing this in parallel with picking and packing avoids missing the next flight out.

How fast can a regional road run happen in practice? BOCSIT provides a case of roughly 200 miles covered in about four hours. That is a useful reference point for well‑planned runs and proves that a same‑day window at that distance is realistic when the details are right.

What if the destination has no dock or limited material handling? Ask for a liftgate and, if needed, white‑glove handling. GoUSPack calls out handlers trained for non‑dock sites, safe entry and exit, and secure strapping. Provide site instructions and a contact who will answer the phone.

How do I control costs without risking schedule? Inbound Logistics suggests partial expediting and realistic delivery windows. SmartRoutes adds that route optimization and consistent communication reduce wasted miles and idle time. In my experience, the combination of precise part identification, pre‑staged packaging, and a ready bench of carriers usually saves more than it costs.

Closing

When the plant is quiet and the counter flickers down, you do not need heroics. You need a reliable partner who knows the difference between a guess and a guarantee. Verify the exact part, package it like it matters, choose the right lane, and keep eyes on the chain of custody. The rest is execution. If you want a steady hand the next time a Rockwell module takes a line down, I am ready to run the play.

References

- https://www.advanced-automationinc.com/shipping-delivery?srsltid=AfmBOoq8FzDR7J_tJM0IHODj0Qno0qhN7N2C-XKs8Gg1M8tVreuaDCQn

- https://www.dosupply.com/?srsltid=AfmBOoo6llIDEoC-DmKHAsI3NHacQ5L8FDt-BjpvmLVCt9dYp6YBma6I

- https://www.njtautomation.com/

- https://www.samedaydelivery.com/

- https://blog.shiperp.com/shipping-smarter-for-industrial-machines-components

- https://bocsit.com/blog/local-same-day-courier-manufacturing-parts-components

- https://www.conger.com/reduce-lead-time/

- https://www.curri.com/article/heavy-equipment-delivery-services

- https://deliberatedirections.com/strategies-to-optimize-your-supply-chain-for-faster-deliveries/

- https://www.dispatchtrack.com/blog/delivery-industry

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment