-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Allen-Bradley PowerFlex 525 Alternatives: Choosing Compatible VFDs That Actually Work

This is my linkedin:

As a seasoned expert in the field of automation spare parts, Sandy has dedicated 15 years to Amikon, an industry-leading company, where she currently serves as Director. With profound product expertise and exceptional sales strategies, she has not only driven the company's continuous expansion in global markets but also established an extensive international client network.

Throughout Amikon's twenty-year journey, Sandy's sharp industry insights and outstanding leadership have made her a central force behind the company's global growth and sustained performance. Committed to delivering high-value solutions, she stands as a key figure bridging technology and markets while empowering industry progress.

When a PowerFlex 525 goes down on a critical line, you do not have time for guesswork. Swapping in “something with the same horsepower” is how you end up chasing nuisance trips, fighting torque issues, or rewriting half of a PLC program at 2:00 AM. As a systems integrator who has lived through that, I treat a PowerFlex 525 replacement as an engineering project, not a parts order.

This article walks through how to evaluate alternatives to the Allen-Bradley PowerFlex 525, both inside and outside the Rockwell family. I will lean on published guidance from Rockwell Automation, Industrial Automation Co., Manuals Plus, and others, and layer that with the kind of practical tradeoff thinking you need when production uptime is on the line.

The focus is on compatibility: electrical, mechanical, control, network, and safety. By the end, you should be able to decide when another PowerFlex is the right move, and when third-party VFDs such as Invertek Optidrive P2, Lenze i500, Hitachi SJ‑P1, or ABB ACS580 are better choices in terms of cost, features, or availability.

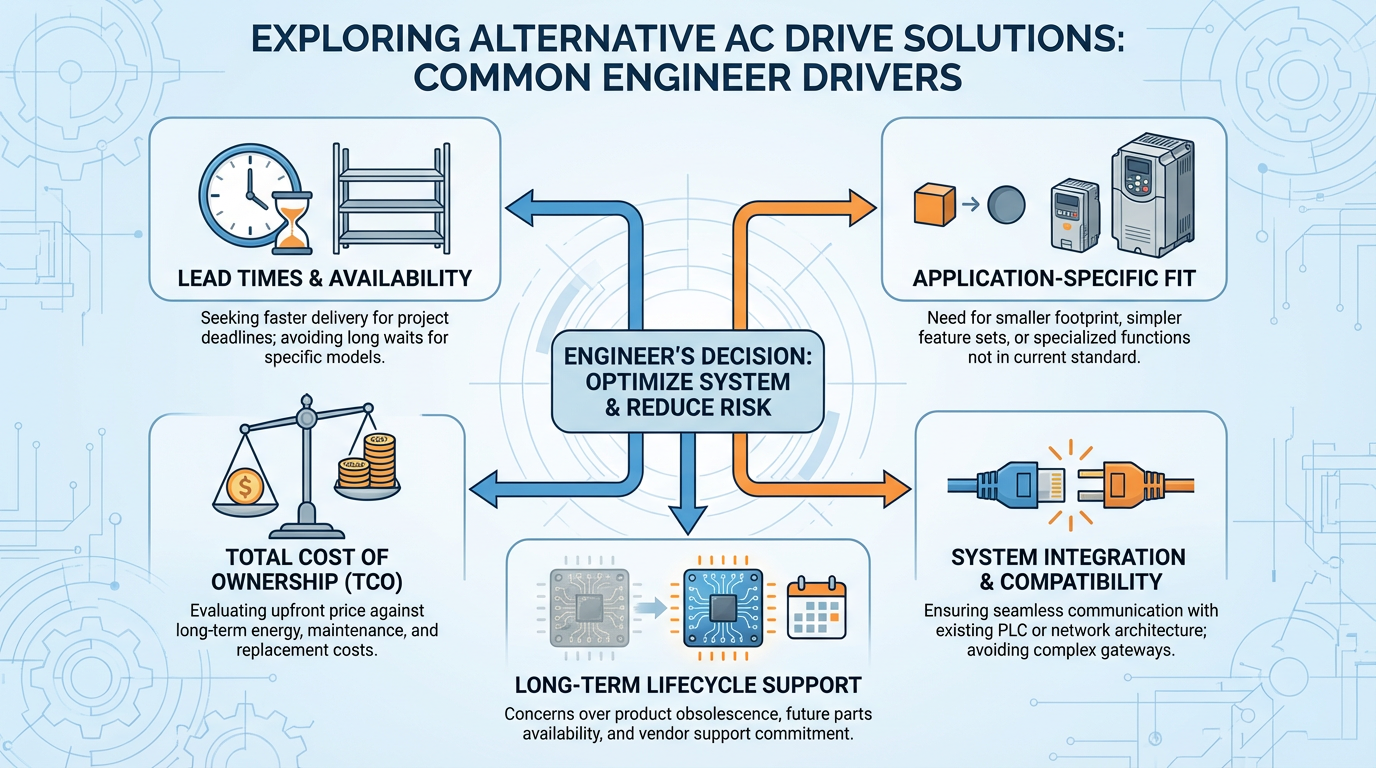

Why Engineers Look For Alternatives To The PowerFlex 525

The PowerFlex 525 is a very capable mid-range VFD. Manuals Plus describes it as a compact drive covering roughly 0.5 to 30 horsepower at about 100 to 600 volts, supporting sensorless and closed-loop vector control, embedded EtherNet/IP, and Safe Torque Off rated to SIL2 / PLd. It is used on everything from HVAC fans to bottling conveyors and can operate in hot environments up to about 158°F with derating.

Despite that capability, many plants actively look for alternatives. Manuals Plus notes that PowerFlex 525 carries a noticeable brand premium, with comparable third-party drives often coming in about twenty to fifty percent cheaper, sometimes cheap enough that users can buy two non-Allen-Bradley drives for the cost of one equivalent PowerFlex. On large projects or multi-drive retrofits, that difference becomes real money.

Lifecycle is another pressure point. Rockwell’s own modernization guidance, summarized by HESCO, shows that popular PowerFlex 4, 40, and 40P drives have already been classified end-of-life as of June 30, 2025, with related variants expected to follow within a few years. That does not mean PowerFlex 525 is going away now, but it is a reminder that even successful product lines have finite lifespans. Obsolescence is a question of “when,” not “if.”

Finally, there is standardization. Some organizations have committed to other ecosystems such as ABB, Siemens, or Lenze. Industrial Automation Co. points out that standardizing on a single drive family across a line reduces spare-parts inventory and simplifies training. In that context, a PowerFlex 525 sitting in the middle of a non-Rockwell plant can be more of a liability than an asset.

So the question is not “Is the PowerFlex 525 a good drive?” It clearly is. The question is whether it is the best fit for your next replacement or upgrade, given cost, lifecycle, and the control architecture you are building toward.

What “Compatible Alternative” Really Means

Replacing a VFD, whether PowerFlex 525 or any other model, is not a simple horsepower swap. Industrial Automation Co. is very clear that end-of-life replacements are precise engineering tasks because they directly affect control performance and system reliability.

In practice, compatibility has four main dimensions: electrical, mechanical, control and networks, and safety. Getting all four right is how you avoid unpleasant surprises on startup.

Electrical Fit: Voltage, Current, And Load Type

The first gate is straightforward: the new drive’s input voltage must match the plant supply. Industrial Automation Co. calls out the common low-voltage levels as about 230 volts, 400 to 480 volts, and 600 volts AC. The output current rating must meet or exceed the motor’s full-load amps, especially for cyclic or high-inertia loads.

Do Supply emphasizes that full-load amps, not horsepower, should drive VFD sizing. They recommend selecting a drive whose amp rating is slightly higher than the motor’s full-load current for constant-torque applications to improve reliability and extend the life of both the motor and the drive. When single-phase input is involved, they note that many applications require oversizing by roughly a factor of two on current to keep things stable.

Load type matters just as much. Industrial Automation Co. differentiates between variable-torque loads such as fans and centrifugal pumps, where torque follows a squared relation to speed, and constant-torque loads such as conveyors, mixers, and extruders. Variable-torque loads benefit from energy-saving modes and quadratic torque behavior. Constant-torque loads demand sensorless or closed-loop vector control to hold torque and speed under changing load.

Any PowerFlex 525 alternative must support the right control mode for your load class. The drives highlighted in the Manuals Plus article, including Invertek Optidrive P2, Lenze i500/i550, Hitachi SJ‑P1, and ABB ACS580, all support standard V/Hz and sensorless vector control, with options for encoder-based closed loop where tight speed or torque regulation is needed.

Mechanical Fit And Environmental Conditions

The second dimension is whether the new drive physically fits your panel or machine. Industrial Automation Co. reminds engineers that frame size, mounting orientation, cooling method, and enclosure rating (IP or NEMA) dictate whether a supposed replacement is a clean fit or a mechanical rework.

Rockwell’s own guidance for the PowerFlex 525 calls for vertical mounting, panel or enclosure installations with appropriate IP ratings, and clearances on the order of about 2 inches top and bottom for cooling. The Manuals Plus summary notes that the 525 can run in ambient temperatures up to roughly 158°F with derating. Alternatives have their own rules. Invertek Optidrive P2, for example, operates at full load up to about 122°F with thermal derating as high as around 140°F, and is offered in IP20, IP55, and IP66 / NEMA 4X enclosures for panel, wall, or harsh-duty mounting.

Lenze i500 cabinet drives push mechanical flexibility in a different way. Manuals Plus notes that they use very slim housings, as narrow as roughly 2.4 inches for smaller sizes, and support zero-clearance side-by-side mounting without derating up to about 15 kilowatts. The decentralized Lenze i550 Protec variant offers IP66/NEMA 4X protection in the approximate half to one hundred horsepower range for direct on-machine mounting, often with integrated disconnect switches.

Ignoring these mechanical details leads to panel hot spots, unexpected derating, or control cabinet rebuilds. A compatible alternative must either fit the existing space envelope and cooling pattern, or you must consciously plan the mechanical changes.

Control Modes, Networks, And Safety

If the drive only had to turn a motor, this would be easy. In a modern plant, the VFD is just as much a network node and safety component as a power converter.

Control-wise, the PowerFlex 525 and its peers support classic volts-per-hertz control as well as sensorless vector. Rexel’s modernization notes emphasize that PowerFlex 40 and 525 are not true torque-regulation drives, even with sensorless vector; when dedicated torque or position control is needed, Rockwell recommends drives such as PowerFlex 753 or 755 from the 750 series instead.

Network compatibility is a recurring theme in Industrial Automation Co.’s migration guidance. Replacement drives need to speak the plant’s language, whether that is EtherNet/IP in Rockwell systems, Modbus RTU or Modbus TCP in more open architectures, or bus systems such as PROFINET, PROFIBUS, CANopen, or DeviceNet. The PowerFlex 525 has embedded EtherNet/IP and an Add-On Profile in Studio 5000, making it a very natural choice in CompactLogix or ControlLogix projects. PowerFlex 523, by contrast, only offers RS‑485 Modbus RTU and is positioned as a low-cost, mostly standalone drive.

Third-party alternatives can be just as capable, but the details vary. The Lenze i500 series uses a modular communication slot that Manuals Plus notes can accept interfaces such as EtherNet/IP, PROFINET, EtherCAT, Modbus TCP, CANopen, and Profibus, and even provides built-in wireless commissioning via WLAN. ABB’s ACS580 family, cited by Industrial Automation Co., supports common protocols including Modbus and can integrate dynamic braking and DC chokes for power-quality control. The key is to confirm that whatever you choose can be mapped into your PLC in a way that preserves control-word and status-bit behavior, or that you are willing to modify the logic.

Safety is the last and often most overlooked dimension. PowerFlex 525 includes Safe Torque Off inputs as standard, rated to SIL2 / PLd according to Industrial Automation Co. Manuals Plus notes that Lenze i500 and i550 can reach STO levels up to SIL3 / PLe when outfitted with the appropriate safety modules, which exceeds the PowerFlex 525’s rating on paper. In some machines, that difference matters; in others, the limiting factors are elsewhere in the safety chain. Either way, a compatible replacement must satisfy your risk assessment and machine-safety standards.

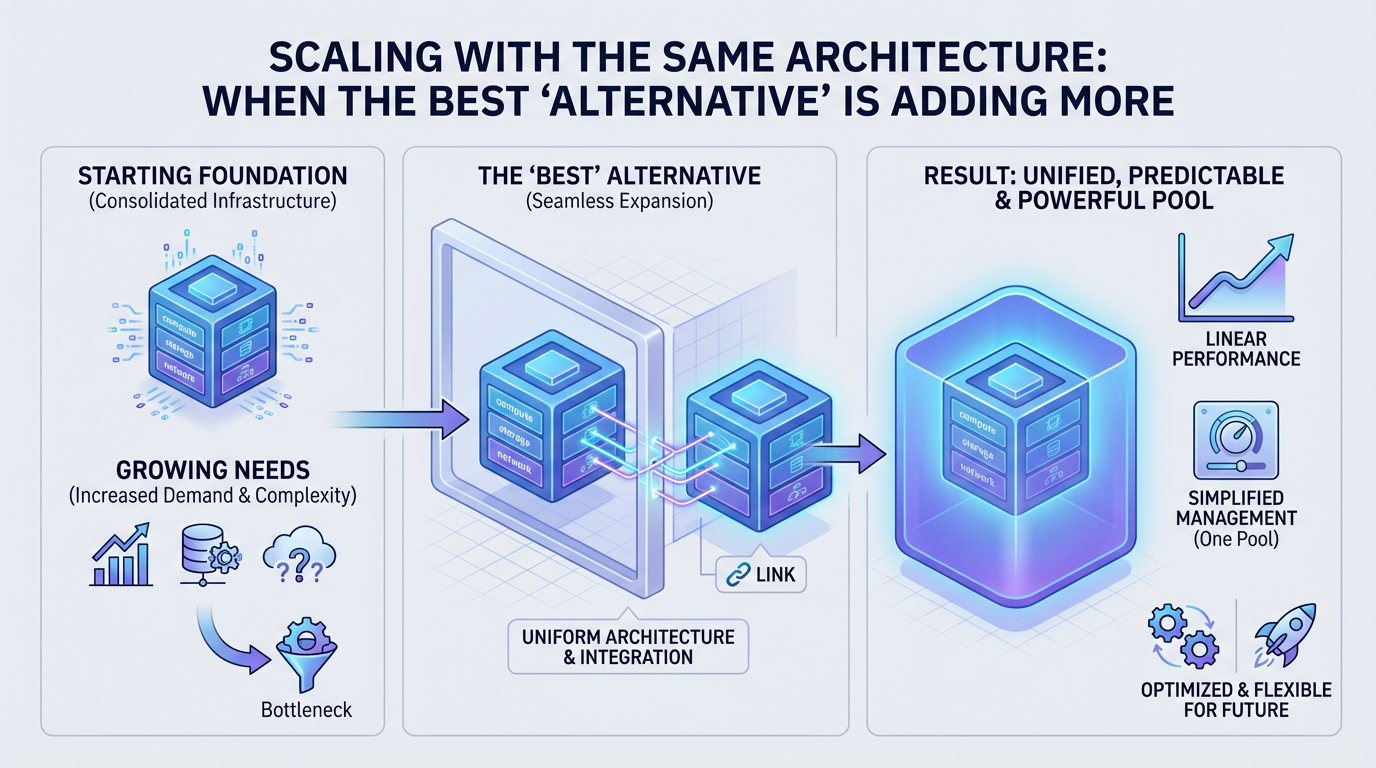

When The Best “Alternative” Is Another PowerFlex

Before jumping to a different brand, it is worth asking if a different PowerFlex family member would solve your problem with fewer unknowns. For many plants deeply invested in Allen-Bradley controllers and EtherNet/IP, staying in the Rockwell ecosystem still makes a lot of sense.

PowerFlex 523: A Leaner Alternative For Simple Machines

Industrial Automation Co. describes the PowerFlex 523 as the entry point to Rockwell’s newer 520 series. It shares physical size ranges and accessories with the 525 but is positioned as a standalone, low-cost drive for basic motor control. It is aimed at conveyors, pumps, and fans where manual or simple analog speed control is enough and no Ethernet networking or advanced safety is required.

Compared with PowerFlex 4M, the 523 brings modern features such as flexible programming, zero-stack mounting that saves panel space, sensorless vector control for better torque performance, and onboard 24-volt I/O that can handle small standalone tasks without a PLC. It covers up to about thirty horsepower at six hundred volts. Pricing in the Industrial Automation Co. notes starts around the mid-four-hundred dollar range for small, single-phase units, reaching several thousand dollars at the upper end.

The tradeoff is connectivity. The 523 supports RS‑485 Modbus RTU, but it does not include embedded EtherNet/IP or integrated Safe Torque Off the way the 525 does. If your existing 525 is only being driven by hardwired start/stop and a simple analog speed reference, and there is no functional safety requirement, a 523 can be a practical, lower-cost alternative that still keeps you within the Rockwell family.

Staying With PowerFlex 525 For Networked, Safety-Critical Systems

For more complex systems, PowerFlex 525 remains the more appropriate choice. As Industrial Automation Co. notes, it is network-ready out of the box, with embedded EtherNet/IP, tag-based control, and Add-On Profile support in Studio 5000. That makes it easy for PLC programmers to integrate the drive, access diagnostics, and perform changeouts quickly.

Safety is another differentiator. Every PowerFlex 525 includes Safe Torque Off inputs rated to SIL2 / PLd. Rexel’s modernization guide explains how STO in the 525 disables torque production without cutting mains power, which makes it very attractive in safety-centric designs where you want to avoid fully de-energizing the drive but still need to remove torque for maintenance or emergencies.

The 525 also supports closed-loop operation using encoder feedback, which improves speed and position accuracy compared with sensorless modes. HESCO notes that while the 525 does not provide full torque or position control like the 750 series, its closed-loop capabilities are sufficient for many conveyors, robotics, and CNC-type applications within its roughly thirty horsepower envelope.

There is a cost premium. Industrial Automation Co. estimates the 525 typically runs about fifteen to thirty percent more than the 523. In my experience, when the drive is on a plant network and part of a safety function, that premium often pays for itself in reduced wiring, faster commissioning, and simpler diagnostics. In a tightly integrated Logix system, replacing a failed 525 with another 525 is usually the path of least resistance.

Stepping Up To Other Rockwell Drives

Sometimes the need is not “a cheaper 525,” but “more than a 525.” Rexel’s article on migrating from PowerFlex 40 to 525 makes an important point: both 40 and 525 are primarily speed-regulating drives with vector modes; they are not torque-following drives. When an application requires true torque control or more advanced positioning, Rockwell recommends the PowerFlex 753 or 755, which sit in the 750 series.

Industrial Automation Co. also points out that if you need more than about thirty horsepower on 480 or 600 volt systems, or a longer lifecycle roadmap than the 520 series, looking at other Rockwell families (or even medium-voltage solutions) can be more appropriate. In those cases, the “alternative” is not a competitor but a different tier of PowerFlex.

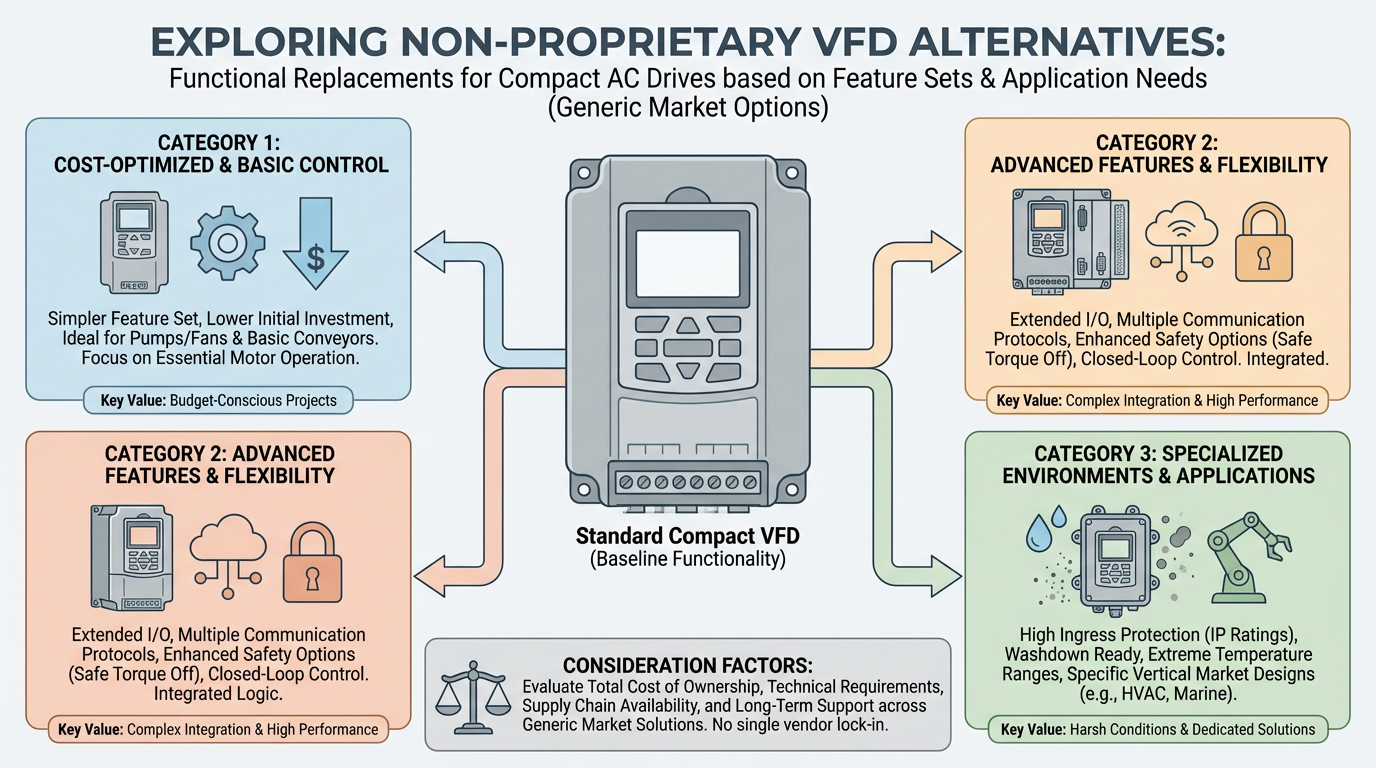

Non-Allen-Bradley Alternatives To PowerFlex 525

If you are willing to move away from Allen-Bradley, Manuals Plus highlights several compelling third-party VFDs that can stand in for a PowerFlex 525 while often lowering cost and adding flexibility. The common theme is that these drives come from established manufacturers, meet key international standards such as IEC 61800, and carry UL/cUL and CE marks, so they are legitimate industrial products, not bargain-bin hardware.

Here is a high-level comparison based on the cited sources.

| Drive family | Approx power range from sources (HP) | Environmental and mechanical notes from sources | Safety and compliance notes from sources | Cost positioning from sources |

|---|---|---|---|---|

| Allen-Bradley PowerFlex 525 | About 0.5 to 30 HP on roughly 100–600 V | Compact, panel-mounted; operates up to around 158°F with derating | Sensorless and closed-loop vector; STO rated SIL2 / PLd; used on pumps, fans, conveyors, mixers | Carries a brand premium; third-party drives can be about 20–50% cheaper |

| Invertek Optidrive P2 | About 1 to 400 HP on roughly 200–600 V | Heavy-duty overload (150% for 60 seconds, 200% for 4 seconds); up to about 122°F at full load with derating to around 140°F; enclosure options include IP20, IP55, and IP66 / NEMA 4X | Runs induction, permanent-magnet, brushless DC, and synchronous-reluctance motors; encoder options for true closed loop; meets IEC 61800 and major global certifications | Often noticeably cheaper per horsepower than comparable PowerFlex 525 units, especially for harsh or decentralized installations |

| Lenze i500 / i550 Protec | Roughly 0.33 to 175 HP for cabinet units; about 0.5 to 100 HP for IP66 / NEMA 4X Protec | Very slim housings; zero-clearance side-by-side mounting without derating up to about 15 kW; decentralized Protec for on-machine mounting | Supports induction and permanent-magnet motors; optional encoder-based closed loop; STO up to SIL3 / PLe with safety module; modular communication with options such as EtherNet/IP, PROFINET, EtherCAT, Modbus TCP, CANopen, Profibus; built-in WLAN for diagnostics | In the 0.5 to 30 HP range, often replaces PowerFlex at a fraction of the cost, with some users obtaining two Lenze units for the price of one Allen-Bradley drive |

| ABB ACS580 | Not specified numerically in the cited notes; presented as a general-purpose, high-performance family | Supports accessories such as dynamic braking and DC chokes; used in a wide range of industrial applications | Offers advanced motor-control functions, modern fieldbus options such as Modbus RTU/TCP, and compliance with safety and EMC standards | Typically lower purchase cost and fewer proprietary ecosystem constraints than PowerFlex 525 in many projects |

The table does not cover every feature, but it shows the pattern: modern third-party drives can match or exceed PowerFlex 525 capabilities in many areas, sometimes at significantly lower purchase cost.

Invertek Optidrive P2: High Overload And Harsh Environment Specialist

Manuals Plus describes Invertek’s Optidrive P2 as a wide-range VFD that covers about one to four hundred horsepower across roughly two hundred to six hundred volt supplies, with heavy-duty overload ratings of about one hundred fifty percent for sixty seconds and two hundred percent for four seconds. It can deliver up to about two hundred percent torque at zero speed and supports induction, permanent-magnet, brushless DC, and synchronous-reluctance motors, with optional encoder feedback for true closed-loop control.

From a hardware standpoint, every P2 includes a built-in EMC filter and an integral braking transistor. In practice, that means you often do not need separate line filters or braking choppers for many applications, which reduces panel complexity and cost. The drive is available in IP20, IP55, and IP66 / NEMA 4X enclosures, and it runs at full load up to roughly 122°F, with derating toward about 140°F.

Compared with a PowerFlex 525, P2’s main advantages are its broader power range, heavy-duty overload capability, strong low-speed torque, and enclosure options suitable for washdown or outdoor duty. Manuals Plus notes that per-horsepower pricing is often noticeably lower than an equivalent 525, especially when you consider the built-in EMC and dynamic braking functions. That makes P2 attractive for decentralized or harsh installations where you would otherwise add external components to a panel-mounted PowerFlex.

Lenze i500 And i550 Protec: Compact And Decentralized Architecture

Lenze’s i500 series takes a different angle. Manuals Plus reports that these cabinet drives span roughly one-third to about one hundred seventy-five horsepower with very narrow housings and support zero-clearance, side-by-side mounting without derating in the lower power ranges. The i550 Protec variant extends the concept onto the machine, offering IP66 / NEMA 4X protection from about half a horsepower to roughly one hundred horsepower, often with integrated local disconnects.

Energy efficiency is a core design goal. The i500 series includes regenerative energy handling that can reduce or even eliminate the need for braking resistors in some applications, along with flux-optimization and sleep modes for pumps and fans. The result is lower energy consumption, reduced heat in the cabinet, and less stress on mechanical components.

From a control and safety perspective, Lenze i500 drives support both induction and permanent-magnet motors and can use encoder-based closed-loop vector control for tighter regulation. Manuals Plus notes that, with the right safety module, they can deliver Safe Torque Off up to SIL3 / PLe, which is a higher rating than the PowerFlex 525’s SIL2 / PLd STO. Their modular communication slot system can be populated with interfaces such as EtherNet/IP, PROFINET, EtherCAT, Modbus TCP, CANopen, and Profibus, and some configurations offer built-in wireless connectivity for commissioning and diagnostics.

Practically, that combination allows very flexible machine architectures. Slim cabinet units can pack many axes into a small panel, while Protec units can be mounted directly on the machine frame near the motor, shortening cable runs and improving electromagnetic performance. Manuals Plus also notes that, in the half to thirty horsepower range, Lenze drives are often priced so competitively that some users can buy two of them for the cost of one PowerFlex 525. In multi-drive systems, that changes the economics significantly.

Hitachi SJ‑P1 And ABB ACS580: General-Purpose Workhorses

The Manuals Plus comparison also mentions Hitachi’s SJ‑P1 and ABB’s ACS580 as high-performance, general-purpose alternatives. While the brief in the research notes does not list their full specifications, it emphasizes that they provide advanced motor-control functions, modern fieldbus options, and compliance with major safety and EMC standards.

Industrial Automation Co. specifically calls out ABB’s ACS580 in the context of power-quality and energy-saving features. They note that ACS580 drives, along with similar modern families, support advanced torque-boost algorithms, braking options, and the use of EMC filters, DC chokes, and line reactors to manage harmonics and voltage spikes. These accessories, when correctly sized, help reduce nuisance tripping, protect both drives and motors, and extend overall equipment life.

The common message about these non-Rockwell drives is not that they are “cheap clones,” but that they are mature, well-supported products that can deliver equivalent or better performance than a PowerFlex 525, often at lower purchase cost and without locking you into a single proprietary ecosystem. The tradeoff is that you must invest engineering effort up front to ensure proper electrical sizing, mechanical fit, and network integration.

How To Engineer A PowerFlex 525 Replacement The Right Way

Regardless of which alternative you choose, the process matters at least as much as the brand. Industrial Automation Co., Rexel, and others converge on a similar workflow for drive migration.

Start by documenting the existing installation. That means recording motor nameplate data, including voltage, full-load amps, base frequency, and nominal speed. Do Supply underscores that full-load current is critical for sizing. On the drive side, record supply voltage, enclosure type, any external line reactors or filters, braking resistors, and key parameters that define behavior. Rockwell’s own guidance and SolisPLC tutorials recommend capturing parameters such as motor data, start and speed sources, acceleration and deceleration times, and frequency limits. In a Logix system, also note the drive’s I/O image definition and any custom tags that reference it.

Next, match electrical and mechanical fundamentals. Using the approach described by Industrial Automation Co., verify that candidate drives support the plant’s line voltage and that their continuous and peak current ratings meet the motor’s needs under worst-case loading. Check that their form factor fits your panel or machine, that the cooling concept (convection versus forced air) aligns with your enclosure, and that their IP or NEMA ratings meet the environment where they will be installed. For harsh or washdown areas, it might be more cost-effective to switch to a decentralized drive like Lenze i550 Protec or an IP66-rated Optidrive P2 than to keep rebuilding stainless enclosures around panel drives.

Then, confirm control modes, network protocols, and safety functions. If you are replacing a PowerFlex 525 that is integrated over EtherNet/IP into a CompactLogix or ControlLogix controller, you need to decide whether to preserve EtherNet/IP with a compatible third-party drive, switch to another protocol such as Modbus TCP, or revert to hardwired control. Industrial Automation Co. advises verifying not just that the protocol is supported, but that the drive’s control-word and status-word mapping can be aligned with existing PLC logic or that you are willing to modify the code.

For safety, map your existing risk reduction to the new device. If the 525’s STO inputs are part of a safety chain designed to SIL2 / PLd, your alternative drive must offer equivalent or better functionality, whether that is a built-in STO circuit, external safety relay, or higher-level safety bus. Manuals Plus notes that Lenze i500 with safety modules can reach SIL3 / PLe, which may be attractive when upgrading the entire safety concept.

Before commissioning, Industrial Automation Co. recommends verifying firmware compatibility, documenting any motor-tuning values, and planning for EMC and power-quality measures. Their guidance highlights the importance of EMC filters, DC chokes, and line reactors where drives do not have sufficient built-in impedance, and the use of properly sized braking resistors when dynamic braking is required. Rexel’s Rockwell modernization notes add details about correct grounding practices: direct, low-impedance bonds from drive to motor, shielded VFD cables, and careful termination of shields and grounds to keep high-frequency noise from migrating through the plant.

Commissioning should be deliberate. Bring up the new drive under no-load or light-load conditions, verify rotation, current draw, and fault-free operation, then tune acceleration, deceleration, and speed limits rather than accepting defaults. Industrial Automation Co. and Rockwell examples show that simply increasing ramp times from default values to around five seconds can dramatically improve stability in applications like bottle cappers, eliminating surging and jams.

Finally, treat documentation and parameter backups as part of the deliverable, not an afterthought. Multiple sources, including Industrial Automation Co. and SolisPLC, stress the importance of backing up parameter sets to removable media or a PC, labeling terminals and motor leads, and storing a configuration sheet in the control cabinet. When a drive fails in the future, a well-documented configuration is often the difference between a thirty-minute swap and a multi-hour reconstruction effort.

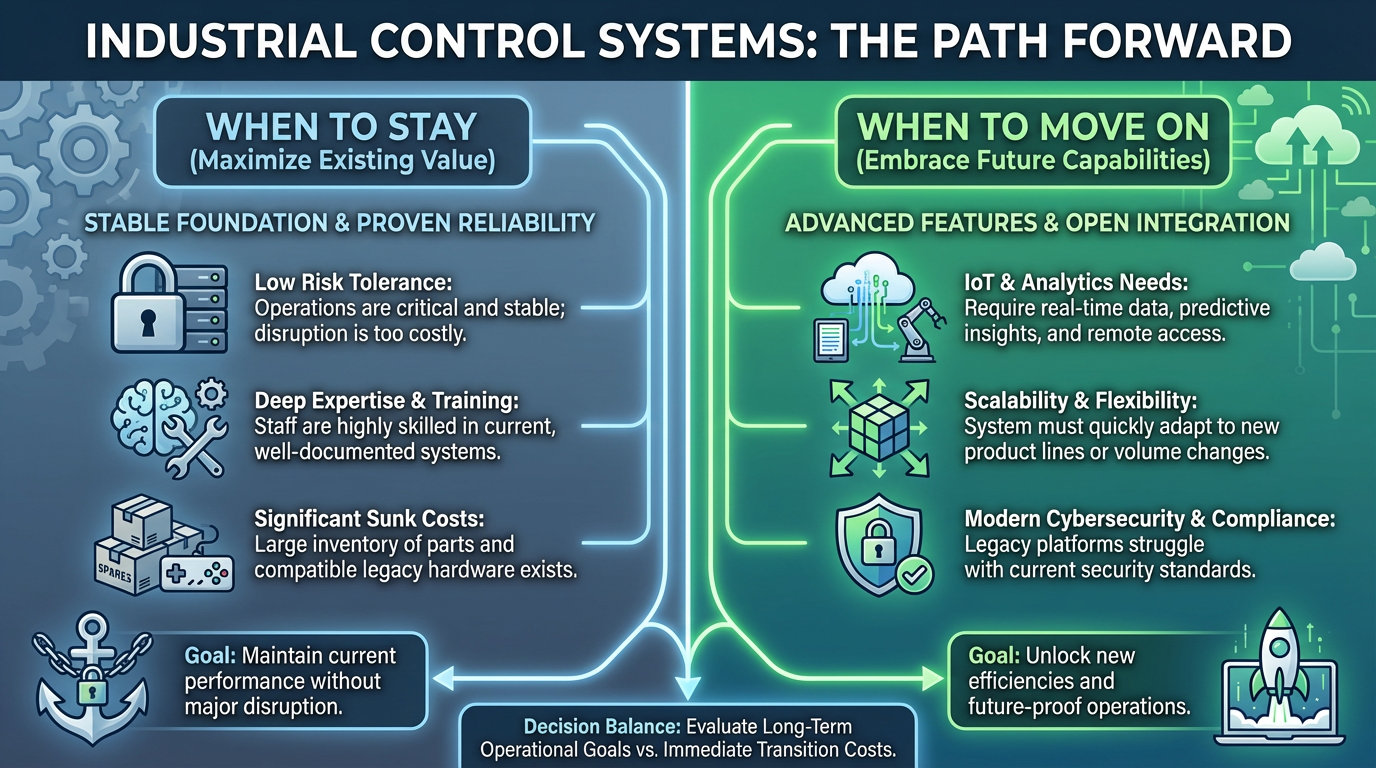

When To Stay With Allen-Bradley And When To Move On

In my experience, the decision comes down to architecture and risk tolerance.

If your plant is built around Allen-Bradley PLCs, EtherNet/IP, and PowerFlex drives, and you have a maintenance team already comfortable with Studio 5000 and Rockwell safety components, staying with PowerFlex 525 or its close relatives usually minimizes friction. The embedded network integration, Safe Torque Off, and removable control cores that Industrial Automation Co. highlights are very real advantages in that environment.

On the other hand, if you are facing significant cost pressure, struggling with lead times, or planning a broader standardization across brands, the alternatives outlined by Manuals Plus and Industrial Automation Co. are worth serious consideration. Invertek Optidrive P2 gives you heavy-duty overload capability, wide power range, and harsh-environment options at attractive prices. Lenze i500 and i550 Protec offer compact cabinet designs and decentralized IP66 solutions with strong safety and communication features, often at a fraction of the cost in the half to thirty horsepower band. ABB’s ACS580 and Hitachi’s SJ‑P1 provide general-purpose, high-performance control with modern networks and power-quality accessories.

None of these options is inherently better or worse than a PowerFlex 525. They are tools with different tradeoffs. The right choice for your project is the one that fits your electrical and mechanical constraints, integrates cleanly with your control and safety architecture, and delivers an acceptable lifecycle cost and risk profile.

Frequently Asked Questions

Can I drop in a non-Allen-Bradley drive without touching the PLC program?

It is rarely that simple. Industrial Automation Co. stresses that different drives represent control words, status bits, and diagnostics differently, even when they share a protocol such as EtherNet/IP or Modbus. When replacing a PowerFlex 525 with a non-Rockwell drive, you should expect to at least review and often modify the PLC program to accommodate new I/O images, parameter structures, and fault handling.

Can I select a replacement based only on horsepower?

Industrial Automation Co. is explicit that horsepower alone is not enough. You must match input voltage, ensure the drive’s continuous and peak current ratings meet or exceed the motor full-load amps, consider overload demands for high-inertia or cyclic loads, and confirm that the control mode (variable torque versus constant torque, sensorless versus closed loop) matches the application. Do Supply adds that sizing based on full-load amps with a margin is far more reliable than simply matching horsepower.

Will third-party drives really save money after engineering time is included?

Manuals Plus notes that many non-Allen-Bradley drives are about twenty to fifty percent cheaper than an equivalent PowerFlex 525, sometimes allowing you to purchase two alternative units for the price of one Allen-Bradley drive. That saving must be weighed against engineering and training time to integrate a new platform. In my experience, for one or two isolated drives in a heavily Rockwell-centric plant, the engineering overhead can outweigh the savings. For larger retrofits or lines where you are already moving away from a single-vendor ecosystem, the cost and availability advantages of alternatives often justify the integration effort.

At the end of the day, choosing a PowerFlex 525 alternative is less about brand loyalty and more about disciplined engineering. If you approach it the way you would any serious control project—grounded in motor data, load behavior, network design, and safety requirements—you can confidently deploy compatible VFDs from Allen-Bradley or other manufacturers and sleep at night knowing the line will start when operations calls at 5:00 AM.

References

- https://www.plctalk.net/forums/threads/opion-poll-best-vfds.111280/

- https://blog.hesconet.com/powerflex-4-end-of-life

- https://www.asteamtechno.com/rockwell-automation-powerflex-vfd-a-complete-guide/?srsltid=AfmBOopVzSDEDmDHha0FsVg_25zwsqpzCD6nO-KG1wKuckSSJEMKE_6d

- https://manuals.plus/m/db060d26b4cebd5b0c7c74c201be3d819210a4dbd1eae37be6c1074c02624801

- https://www.precision-elec.com/powerflex-525-replacement-guide-cost-saving-vfd-alternatives/?srsltid=AfmBOoqCaVXf1QPhpwuFqoUcPli4SzqcHIpVF-zWiBarAlZMmIbX3XNu

- https://www.solisplc.com/tutorials/powerflex-525

- https://amatrol.com/product/ac-motor-drive-troubleshooting-training/

- https://industrialautomationco.com/blogs/news/how-to-set-up-and-program-your-allen-bradley-powerflex-525-vfd-a-complete-engineer-s-guide-4?srsltid=AfmBOoq5MxoPZjIrg_y6Ywo_ZjQqF9h2fCbzcet_gziGRVr2ZQQqdQCM

- https://pages.rexelusa.com/blog/automation/drive-modernization-part-vi-powerflex-40-to-powerflex-525

- https://www.udemy.com/course/variable-frequency-vfd-powerflex-525-plc-programming-rslogix-5000/?srsltid=AfmBOoqbBzT89m8wE8KshVyGd5hYP3L2hgltq9hkEg3pB_oWAqqTXTal

Keep your system in play!

Related Products

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment