-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Emergency Fanuc CNC Parts Delivery: Urgent Fanuc Machining System Components

When a Fanuc-based machining center goes dark in the middle of a production run, nobody in the plant cares whether the root cause is a servo amplifier, a power supply, or a control module. They care that every hour of unplanned downtime is burning cash, missing customer ship dates, and putting hard-won contracts at risk.

As a systems integrator who gets those 2:00 AM phone calls, I can tell you: the difference between a painful incident and a real crisis is almost always whether you have a realistic strategy for emergency Fanuc parts delivery. Not a marketing slogan, but a concrete mix of spare parts planning, supply-chain discipline, and partners who actually deliver when your spindle is at a dead stop.

In this article I will walk through how to think about urgent Fanuc CNC component availability, drawing on proven practices from CNC supply-chain optimization, predictive maintenance, and spare parts management. The focus is practical: what you can do today so the next failure is a controlled event, not a catastrophe.

When A Fanuc Control Fails, The Clock Starts

For modern CNC machining, unplanned downtime is brutal. Research from Messer Cutting Systems on CNC cutting equipment shows that unplanned machine downtime routinely costs thousands of dollars per hour once you factor in lost production, overtime, premium emergency parts, and the ripple effects on delivery schedules. Their data on predictive maintenance programs points to 70–75 percent less unplanned downtime and 10–20 percent higher overall equipment effectiveness when failures are anticipated instead of reacted to.

Fanuc-controlled machining centers, lathes, and grinders tend to sit in critical paths: key engine components, aerospace structures, precision medical parts, and high-value tooling. When a control, axis drive, or spindle amplifier fails, you are not just losing machine time; you are endangering entire production plans downstream.

What turns this technical problem into a business crisis is the lead time on the replacement component. If it takes days to diagnose, another day to argue with the parts supplier, and a week to actually receive the right Fanuc board, the economic damage dwarfs the cost of the component itself.

That is why “emergency Fanuc parts delivery” is not primarily a logistics slogan. It is a disciplined way of designing your supply chain, inventory, and maintenance approach around the reality that some failures will always be urgent and that the cost of being unprepared is far higher than a few extra components on a shelf.

What Emergency Fanuc Parts Delivery Really Means

In practice, emergency Fanuc parts delivery is not just “overnight shipping.” For a plant that runs critical Fanuc-based machines, emergency support has several simultaneous requirements.

First, the correct component must be identified quickly and accurately. Many failures appear similar at the operator panel but trace back to different root causes: drives, power modules, feedback cables, or even upstream power issues. If your technical and diagnostic process is weak, you can easily burn a day waiting for a part that never had a chance to solve the problem.

Second, the component itself needs to be available, tested, and ready to drop in. That is where spare parts management and supplier capabilities matter. Research on spare parts management in mechanical engineering emphasizes classifying parts, maintaining differentiated service levels, and prioritizing high‑criticality components for better availability. When you translate that into a Fanuc context, you are talking about the difference between having a known-good spindle drive on the shelf versus praying the broker you just found can ship something that works.

Third, the physical handling and packaging of that component must preserve its integrity. Articles on transporting high-precision machined parts point out that modern parts often hold micro-level tolerances and can be damaged by vibration, poor orientation, or contamination, even when there is no obvious visible damage. Fanuc drives, power units, and control boards fall squarely into this category of sensitive hardware. The way they are packaged, braced, and transported matters, especially if you are shipping across the country on short notice.

Finally, the logistics path has to be reliable. Timely delivery of CNC machined parts, according to manufacturers with long experience in this space, is not just a shipping problem; it depends on upstream material availability, capacity planning, and information flow. Emergency parts shipments are no different. If your supplier’s internal scheduling, inventory, or freight processes are weak, a promised next‑day delivery can easily slip into a three‑day outage.

Put simply, emergency Fanuc parts delivery is a system, not a single transaction.

Typical Fanuc CNC Components Under Time Pressure

Most Fanuc-based plants see the same kinds of components become “urgent” over and over again. While exact failure modes are highly application‑specific, certain categories show up frequently in real projects.

Axis and spindle amplifiers sit right at the heart of motion control. When they fail, you are often looking at sudden axis faults, overcurrent alarms, or immediate shutdowns. Replacement drives tend to be high-value items that require careful handling and configuration. Their electronics are sensitive to shock, static, and moisture, just like the high-end machined parts that Frigate and others discuss when they talk about transport-related damage in critical industries.

Control modules and CPU boards form the brains of the Fanuc system. When they fault, the entire machine is out of service. These boards typically rely on precise connectors and sometimes on configuration data that must be transferred or restored correctly. Mistakes here can turn a straightforward swap into an extended recovery.

Power supplies and power modules are another common pain point. Fluctuations in line power, heat, and contamination can all contribute to premature failure. If your operation is not prepared with compatible Fanuc power modules, plus the wiring and protective devices they require, a simple power-related fault can escalate into extended downtime.

Operator panels, I/O modules, feedback devices, and communication units also contribute to urgent failures, especially where safety interlocks or fieldbus networks are tightly integrated. In practice, most plants do not try to stock every possible module; instead they identify a set of “line stoppers” and treat those as critical spares.

From a logistics and handling point of view, these Fanuc components are not fundamentally different from high-value machined parts with tight tolerances. The same logic applies: detailed documentation, robust packaging, controlled chain of custody, and careful inspection upon arrival are all essential to avoid introducing new problems while rushing to solve the old one.

Why Fanuc Spare Parts Lead Times Can Be So Unstable

Many managers assume that if they are buying from a well-known CNC brand, spare parts will always be available with predictable lead times. The reality on the plant floor is more complicated, and the same factors that drive delays in CNC machined parts also drive unpredictable Fanuc spare lead times.

Research on CNC machining supply chains shows that delivery delays often stem from mismatches between capacity and demand, unstable raw-material supply, and weak production management systems. Factories that run at more than about eighty percent of capacity for weeks at a time have very little flexibility to prioritize urgent work. When your Fanuc-compatible part vendor is using the same equipment for new builds, repairs, and refurbishments, their internal queues directly impact your downtime.

Material supply is another bottleneck. CNC machining studies emphasize the importance of multi-sourcing materials, maintaining meaningful on-hand stock, and using real-time inventory systems to avoid procurement delays. The same applies to spares and assemblies that support Fanuc systems. If a vendor relies on a single source for critical components or keeps only minimal stock, they cannot suddenly produce a wave of emergency shipments when supply chains tighten.

Production management and scheduling matter as well. Shops that base their schedules on experience alone, without real-time monitoring or electronic scheduling, tend to drift into what one CNC turning provider describes as a cycle of delay, rush, quality issues, and further delays. On the other hand, suppliers that integrate ERP, manufacturing execution, and real-time monitoring can rebalance their queues faster and protect on-time delivery even when priorities change suddenly.

Finally, logistics networks and shipment models are a major lever. Penta Precision’s work on CNC lead times highlights that traditional one‑off purchase orders rarely give the best results. Instead, call‑off, schedule, and Kanban arrangements allow suppliers to build ahead, stock intelligently, and ship within one to two days once a trigger signal arrives. If you insist on treating urgent Fanuc spares as unplanned purchases every time, you will see more volatility than a plant that has structured agreements and stocking plans with its parts partner.

In short, unstable Fanuc spare lead times are usually a symptom of deeper supply-chain and planning weaknesses, on either your side, your supplier’s side, or both.

Building A Fanuc Spares Strategy Before The First Breakdown

If you want emergency Fanuc parts delivery to work when everything is on the line, the preparation has to happen long before anything fails. The best plants treat Fanuc spares as part of their overall spare parts management strategy rather than an afterthought.

A common starting point, drawn from spare parts management best practices, is to classify components by criticality and demand. For Fanuc systems, that usually means identifying which parts will stop the line entirely if they fail, which will degrade capacity or quality, and which are convenient but not critical. High‑criticality components, such as key drives and power units, justify on‑site stock, while lower‑criticality items may be covered by supplier stock or on‑demand sourcing.

From there, you can design a blend of local inventory, vendor-managed inventory, and rapid procurement. Research from Batchforce and Stecker Machine on CNC supply chains and inventory management shows that strong suppliers use integrated ERP, purchase planning, and safety stock to maintain availability while keeping cost under control. Translating that to Fanuc spares, the most resilient strategies usually include:

| Supply approach | Benefits for Fanuc spares | Trade-offs and risks |

|---|---|---|

| On-site stocked critical spares | Fastest possible replacement, no shipping delay, full control over handling | Higher capital tied up, risk of obsolescence if configurations change |

| Vendor-managed or consignment | Reduced capital load, professional inventory control, high availability for standard items | Requires strong trust and data integration, may be weaker for highly customized Fanuc configurations |

| On-demand procurement | Lowest inventory cost, easy to adapt as machines change | Highest lead-time risk, especially under global supply or logistics disruptions |

Predictive maintenance is a force multiplier for this strategy. Messer Cutting Systems has documented that predictive programs can cut unplanned downtime roughly in half and extend equipment life while reducing maintenance cost. When you monitor Fanuc-based machines for vibration, temperature, and electrical anomalies, you can often spot a drive or power module degrading before it fails. That gives you time to pull from stock, order a replacement, or arrange a refurbish without treating every event as a fire drill.

Finally, data discipline is essential. Effective spare parts management literature emphasizes clean part master data, traceability, and clear ownership between maintenance, production, and purchasing. For Fanuc systems, that means accurate records of part numbers, firmware versions, parameter sets, and backward compatibility. Whenever I walk into a plant that stores Fanuc modules without clear labeling or change history, I can predict with good confidence that their next “urgent” order will include at least one back-and-forth about the correct revision.

What A Reliable Emergency Fanuc Parts Partner Looks Like

Choosing the right partner for urgent Fanuc parts is structurally similar to selecting a CNC machining supplier, and many of the same criteria apply.

Capacity and technical capability come first. Studies on avoiding CNC delivery delays recommend selecting providers with meaningful machine fleets, multi-shift operations, and technicians who understand both the mechanical and control sides. For Fanuc spares this translates into organizations that can test, repair, and configure modules under realistic electrical loads, not just ship boxes.

Supply-chain resilience is just as important. CNC providers that maintain multiple qualified material suppliers, keep meaningful stocks of standard materials, and use incoming inspection to recognized standards tend to have fewer delays. Fanuc parts vendors with similar discipline in their own supply chains are better positioned to maintain availability when everyone else is short.

Production management systems are a clear differentiator. Articles on CNC delivery performance highlight that ERP-based scheduling and real-time monitoring can reduce delivery delays significantly. When a parts supplier runs a digital production hub with real-time order tracking, preventive maintenance, and integrated quality metrics, they can treat on-time delivery as a managed outcome rather than a vague promise. Some turning providers even back this up with legally enforceable delay compensation clauses, aligning their financial incentives with your uptime.

Communication style is another practical test. The best CNC component services handling urgent orders put a dedicated project manager on the job, clarify specifications up front, and provide frequent, honest status updates. The same approach works for Fanuc spares: you want a partner who will tell you within hours, not days, whether a part can ship today, tomorrow, or next week, and what alternatives exist.

Quality control cannot be relaxed just because an order is urgent. CNC articles emphasize that rushed work without robust QC simply trades delay risk for defect risk. For Fanuc components, that means insisting on tested, documented parts with clear warranty terms, even in an emergency. Partners who rely heavily on uncontrolled third-party shops to cut costs expose you to quality and reliability risk, as documented in analyses of on-demand CNC manufacturing and its limitations.

Finally, risk sharing and transparency matter. Providers that formalize delay penalties, disclose how much work is done in-house versus outsourced, and explain their process for protecting intellectual property are signaling that they understand the broader supply-chain impact of their performance. In an emergency, those are the partners you want on your side.

Preparing Your Plant For The Next Fanuc Breakdown

Emergency response starts long before an alarm shows up on the screen. Plants that ride out Fanuc failures with minimal drama usually do a few things consistently.

They treat Fanuc spares as part of a structured procurement and inventory strategy, not as miscellaneous maintenance purchases. Research into optimal procurement strategy in the CNC industry stresses thorough supplier assessment, long-term relationships, and systematic risk management. When you extend that thinking to Fanuc, you end up with a curated set of suppliers for new OEM parts, refurbished components, and field service, each with defined roles, escalation paths, and performance metrics.

They use smarter ordering models instead of perpetual spot buys. Penta Precision’s work on lead time reduction shows that call‑off, schedule, and Kanban arrangements can cut practical lead times to a day or two once the framework is in place. There is no reason you cannot apply the same logic to high‑criticality Fanuc modules: place an overall commitment, let your partner hold stock or partially complete units, and pull them as needed.

They leverage on-demand CNC capability where it makes sense. Articles on on-demand CNC machining show that made‑to‑order models are extremely effective for prototypes and small batches, especially when you avoid heavy tooling. In the context of Fanuc systems, this is ideal for custom brackets, mounting plates, sensor fixtures, and simple mechanical adapters that might otherwise hold up a retrofit or repair. It is not a replacement for OEM Fanuc electronics, and it does carry supply-chain and intellectual property considerations, but it can shave days off peripheral mechanical work around a failed control.

They invest in integrated inventory management. Stecker Machine’s experience with ERP‑driven inventory highlights that integrating orders, planning, and purchasing yields shorter lead times and reliable availability. For Fanuc spares, that means tying your CMMS or maintenance system into your procurement and inventory data so that spare usage automatically feeds back into reordering and budget planning.

Most importantly, they practice. Maintenance, production, and engineering teams walk through what will happen when a critical Fanuc axis drive fails on a Friday night: who is called, what information is collected, which suppliers are contacted, and what authority those people have to approve emergency spend. When that scenario has been thought through and rehearsed, the first real incident tends to be surprisingly calm.

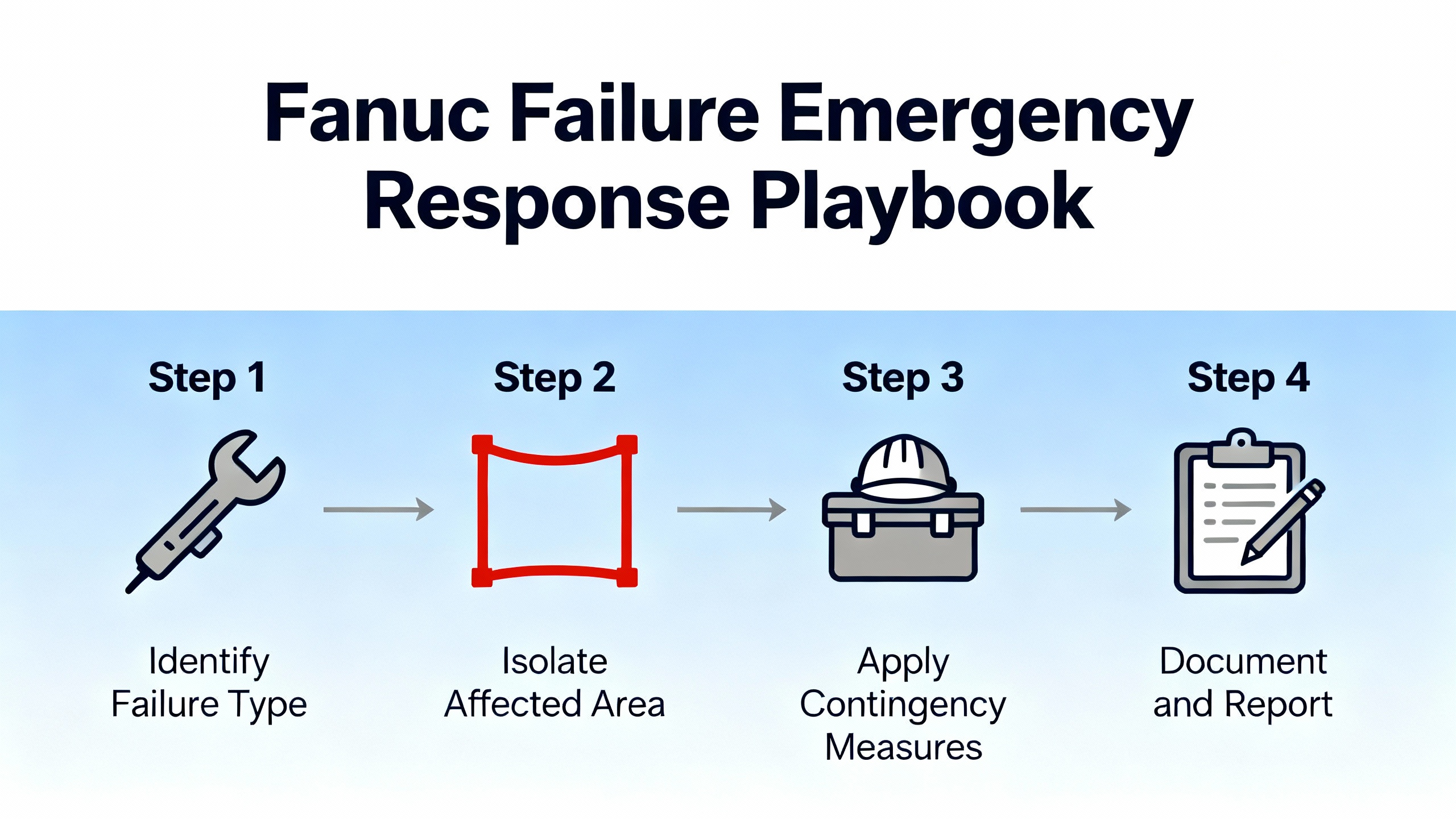

An Emergency Response Playbook For Fanuc Failures

Even with good preparation, the first hour of a Fanuc failure is often chaotic. Having a mental playbook helps.

When a core Fanuc component fails, the technical team’s first task is to stabilize the situation and gather clean information, not to start guessing at part numbers. Capturing alarm codes, operating conditions, and recent changes in configuration or process provides the raw material for accurate diagnosis. Articles on determining CNC delivery dates emphasize that understanding the requirement clearly at the outset is essential; the same is true when the “requirement” is a replacement part.

Next, you triage the failure. Predictive maintenance concepts from Messer Cutting Systems suggest looking at patterns in vibration, power consumption, and operating hours to distinguish between isolated failures and systemic issues. If an amplifier failed because of consistent overheating, simply replacing the module without addressing cooling or contamination will buy you only temporary relief.

Once the likely root cause is identified, you confirm the exact Fanuc part number, option codes, and revision level using documentation and system parameters, not memory. This is where disciplined data management pays off. Many urgent CNC orders fail at this step, with suppliers and customers trading drawings and photos back and forth while the clock keeps ticking.

With that information in hand, you engage your preselected emergency parts partner. The strongest relationships, as described by CNC suppliers who specialize in urgent orders, combine rapid feasibility assessment, reprioritized schedules, and clear communication about what can ship and when. At this point you are not just looking for availability; you are looking for tested parts, known lead times, and a logistics plan that fits your plant’s receiving and installation capabilities.

While the part is in transit, you prepare the machine. That may mean safely de‑energizing, cleaning, and inspecting connectors; documenting wiring; and verifying grounding and environmental conditions. Research on handling high-precision machined parts underscores the value of a documented chain of custody and inspection at each hand‑off. Apply the same rigor to Fanuc components: photograph the failed unit in place, record serial numbers, and document any visible damage.

After installation, you do not declare victory until the machine has been fully tested. That includes verifying axes, spindle behavior, I/O, and safety systems under controlled conditions, not jumping straight into production on the most critical part you run. Plants that skip this verification step often discover, too late, that a secondary issue remains.

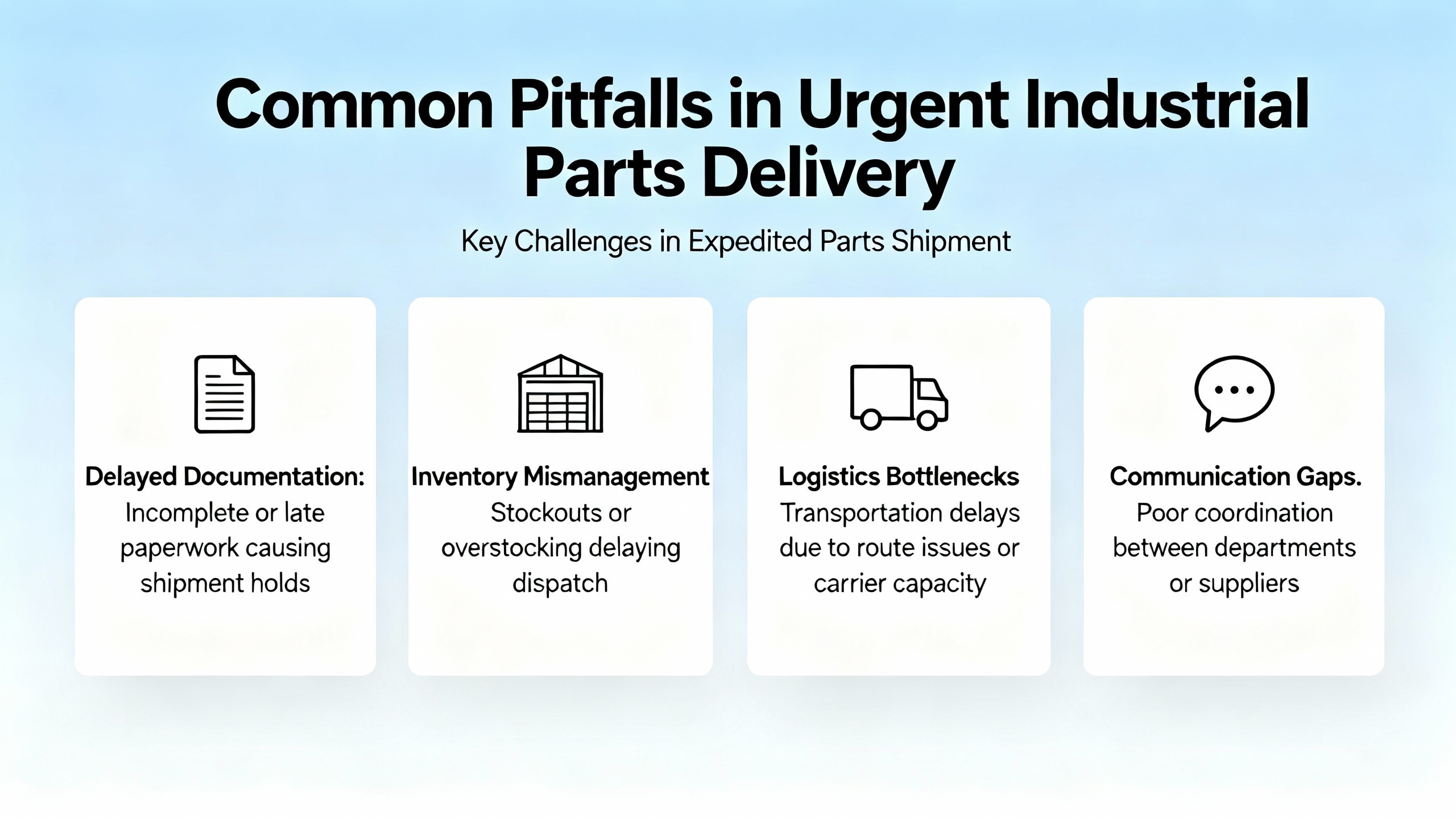

Common Pitfalls In Urgent Fanuc Parts Delivery

In crisis mode, it is easy to make choices that feel fast but cost you more time and money than they save.

A classic pitfall is chasing the lowest upfront price from an unknown broker. CNC sourcing guides warn that poor supplier choices lead to defects, project delays, and added costs, and that advice applies doubly to Fanuc spares. A suspiciously cheap “equivalent” module with vague test history and no meaningful warranty is not a bargain if you have to replace it again after one weekend shift.

Another mistake is relying on suppliers with weak internal processes. Articles on CNC turning services and delivery guarantees show that shops working from rigid, experience-based schedules without data-driven monitoring tend to run into chronic late deliveries and quality issues. When you are betting plant uptime on an overnight shipment, you want a partner whose internal systems can actually support that promise.

Some plants also underestimate intellectual property and data security risks in the rush to share CNC programs, machine parameters, and configuration files. Analyses of on-demand manufacturing highlight that sharing CAD files and designs with unvetted partners opens the door to misuse and leaks. With Fanuc systems, backup files and parameters are as sensitive as mechanical models. They should only be shared under clear confidentiality terms with trusted counterparts.

Finally, there is the temptation to treat every Fanuc failure as a one‑off emergency rather than a signal. Facilities that never circle back to analyze root causes, review supplier performance, and adjust their spares strategy are doomed to repeat the cycle. Continuous improvement, emphasized in multiple CNC supply-chain studies, is just as relevant for Fanuc spares as it is for production processes.

FAQ: Practical Questions On Emergency Fanuc Parts Delivery

How much downtime can better Fanuc spare parts planning really save? Predictive maintenance research on CNC cutting systems shows that data-driven programs can reduce unplanned downtime by up to roughly half and cut unplanned events by around seventy percent. When you combine that with structured spare parts management and reliable suppliers, it is realistic to turn many “emergencies” into planned interventions scheduled during existing downtime windows.

Is it worth stocking expensive Fanuc modules on-site? For components that will stop a critical line instantly, the cost of one or two extra modules on a shelf is almost always lower than the cost of a single extended outage. Studies on spare parts management emphasize prioritizing high‑criticality components for better availability; in most Fanuc installations, that means key axis and spindle amplifiers, power modules, and selected control boards.

Can on-demand CNC machining replace OEM Fanuc spares? On-demand CNC machining is excellent for custom mechanical parts, brackets, and fixtures around your Fanuc system and can sharply reduce lead times for that hardware. However, for the electronic control components themselves, the safest route is still OEM or fully qualified refurbishments from partners who understand Fanuc specifications, safety requirements, and configuration details.

In the end, emergency Fanuc CNC parts delivery is not a miracle service; it is the visible edge of a disciplined system. If you treat Fanuc components as strategic spares, build relationships with capable partners, and back it all with predictive maintenance and clean data, you will not eliminate failures. You will turn them into manageable events that your operation absorbs with confidence instead of panic. That is how a serious plant protects its uptime, its customers, and its reputation.

References

- https://www.ruixing-mfg.com/a-why-timely-delivery-from-cnc-machining-parts-suppliers-is-essential-for-your-business.html

- https://www.acoincncmachining.com/blog/how-does-cnc-component-services-handle-urgent-orders-313503.html

- https://billor.com/strong-supply-chains-cnc-manufacturing-fast-delivery/

- https://www.pentaprecision.co.uk/resources/cnc-machining-lead-times-explained-how-to-get-your-parts-faster

- https://www.creatingway.com/how-to-optimize-the-supply-chain-management-of-cnc-machining-manufacturers-and-improve-product-quality/

- https://www.fictiv.com/articles/top-10-design-tips-for-reducing-cnc-lead-times

- https://kesugroup.com/how-to-avoid-delivery-delays-when-choosing-a-cnc-machining-factory/

- https://www.machinemetrics.com/blog/cnc-setup

- https://www.machining-custom.com/blog/determine-the-delivery-time-for-cnc-machined-parts.html

- https://us.messer-cutting.com/reduce-downtime-predictive-maintenance/

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment