-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Lifetime Technical Support for PLC Systems: What It Includes

This is my linkedin:

As a seasoned expert in the field of automation spare parts, Sandy has dedicated 15 years to Amikon, an industry-leading company, where she currently serves as Director. With profound product expertise and exceptional sales strategies, she has not only driven the company's continuous expansion in global markets but also established an extensive international client network.

Throughout Amikon's twenty-year journey, Sandy's sharp industry insights and outstanding leadership have made her a central force behind the company's global growth and sustained performance. Committed to delivering high-value solutions, she stands as a key figure bridging technology and markets while empowering industry progress.

When you build a plant around programmable logic controllers (PLCs), you are not buying a five‑year gadget. You are building a control platform that will quietly run your production lines for a decade or two, sometimes much longer. MRO Electric notes that PLCs often operate 10 to 20 years under normal conditions and there are real‑world examples of units still running reliably after more than 30 years. Engineers on Eng‑Tips describe a Square D PLC that has been opening and closing a drawbridge since the early 1980s, with original hardware still in place.

That kind of longevity is an asset, but it is also a risk. The longer a PLC system runs, the more it accumulates changes, workarounds, and dependencies on specific people. Lifetime technical support for PLC systems is about managing that entire arc intentionally, from the first commissioning to the day you finally de‑energize the last I/O module and cut over to a new platform.

In this article, I will walk through what “lifetime” support really covers, which elements matter most, and how to evaluate whether your support arrangement is set up to keep your plant fast, safe, and maintainable for the long haul.

What “Lifetime Technical Support” Really Means for PLC Systems

The term “lifetime” can be slippery in marketing copy. In an industrial controls context, it almost never means “forever.” It means “for the practical life of the control system,” which is dictated by hardware wear, environmental stress, vendor obsolescence, and technology change.

Kurita America points out that electronic controls usually age faster than the mechanical equipment they drive. Filters, vessels, or process tanks might have a very long life, but HMIs, PLC chassis, power supplies, and network gear will reach end of support much sooner. MRO Electric stresses that many PLC replacement projects are driven by obsolescence and vendor support policies rather than by outright hardware failure.

So lifetime PLC support is not a promise to keep the exact same CPU and I/O cards running indefinitely. It is a commitment to keep your automation functional, safe, and supportable across generations of hardware and software. That includes proactive maintenance on the current platform and a structured path to the next one.

According to AutomationDirect, PLCs scan inputs, execute the user program, and update outputs continuously in a tight loop. Telstar and Patrion emphasize that they sit at the heart or “central nervous system” of modern plants and the PLC market is growing into the tens of billions of dollars, with steady annual growth projected through 2030. That scale is one reason lifetime support matters: you are not dealing with disposable electronics; you are managing core infrastructure.

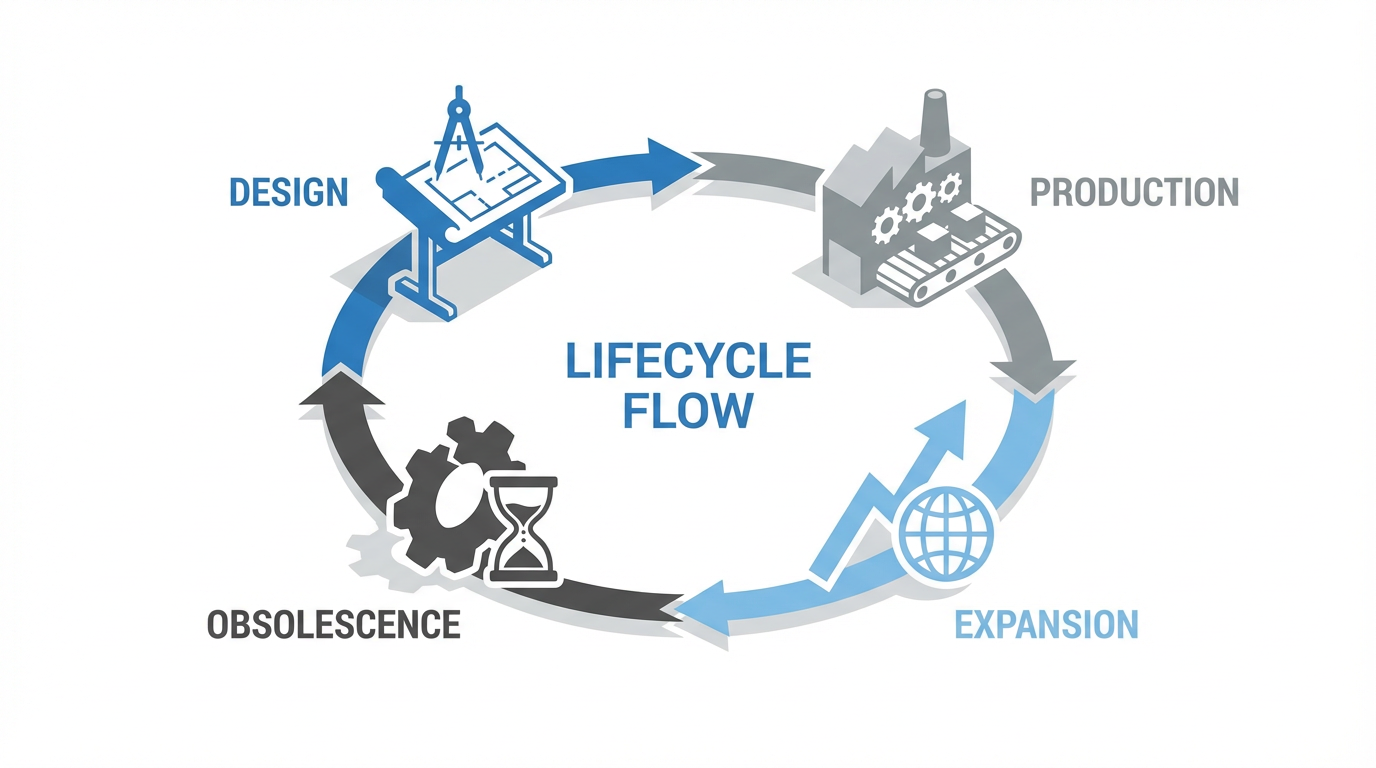

Thinking about lifetime support in lifecycle stages helps.

| Lifecycle stage | What strong PLC lifetime support focuses on |

|---|---|

| Design and commissioning | Correct sizing and selection, clean panel design, standards compliance, testing |

| Stable production | Preventive maintenance, backups, monitoring, documentation, cybersecurity |

| Expansion and process changes | Logic updates, hardware additions, integration with new equipment and systems |

| Late life and obsolescence | Spares strategy, migration planning, staged upgrades, compatibility and training |

A real lifetime support relationship stays engaged through each of these stages rather than just reacting when something breaks.

The Foundations: What You Are Really Supporting

Before diving into contract terms, it is worth being clear about what “PLC technical support” actually covers. A mature support program treats the system as more than just a rack of cards.

The PLC hardware stack

Empowered Automation describes a PLC as a rugged industrial computer: CPU, memory, power supply, and I/O modules tied to real‑world devices. Cloud‑Studio and Automation Electric & Controls highlight how modern PLCs are modular, scalable, and designed for harsh conditions with dust, vibration, and temperature swings. Eng‑Tips and MRO Electric both note that while CPUs can run for decades, I/O modules and field wiring are usually the first points of failure, especially in stressful environments.

Lifetime support therefore has to include:

Continuous awareness of which specific PLC families, firmware versions, and I/O types are installed.

A plan to inspect, clean, and test modules and terminations regularly, as eWorkOrders and LinkedIn’s long‑term maintenance guidance emphasize.

A strategy for spares so a failed module does not turn into days of downtime while you hunt for obsolete parts.

The software and logic

AutomationDirect and Patrion explain that relay logic once had to be rewired physically, whereas PLC behavior is now driven by software in standard IEC 61131‑3 languages like ladder, function block, and structured text. RL Consulting stresses that in custom systems, the program is tailored to the facility’s unique processes, which makes maintenance and documentation even more critical.

From a lifetime support perspective, software includes:

The main control program and all associated routines.

Configuration of communications, safety, and diagnostics.

Version history and change management records.

Backup copies stored securely and tested periodically.

RL Consulting and eWorkOrders both emphasize regular program reviews, verification that logic still matches the current process, and structured backup routines so a corrupted file or hardware failure does not stop production.

The connected OT network

Modern PLCs rarely operate in isolation. Cloud‑Studio and Industrial Automation Co. highlight that PLCs speak Ethernet‑based protocols and tie into HMIs, SCADA, MES, and even cloud analytics platforms. TXOne Networks underscores how this connectivity dramatically increases the cybersecurity attack surface.

Lifetime support therefore has to recognize that you are supporting a control network, not just a controller. That includes switches, routers, firewalls, managed remote access, and the security policies and monitoring tools that surround the PLC.

The people and processes around the PLC

NTT Training points out that without in‑house PLC understanding, companies face long waits and high bills whenever a controller misbehaves. RL Consulting’s clients value clear documentation, operator‑friendly interfaces, training, and responsive service. PEC’s view of industrial technical support is similar: specialized expertise that lets plant staff focus on production instead of fighting infrastructure all day.

Any credible lifetime support model should explicitly address people.

That includes who owns first‑line troubleshooting, how knowledge is transferred, how documentation is kept current, and how support interacts with your maintenance planning tools, such as a computerized maintenance management system, which eWorkOrders highlights in its guidance.

What Lifetime PLC Technical Support Should Include

Different vendors package their services in different ways, but based on the patterns highlighted by RL Consulting, eWorkOrders, TXOne, MRO Electric, Kurita America, and others, there is a core set of capabilities that lifetime PLC support should provide.

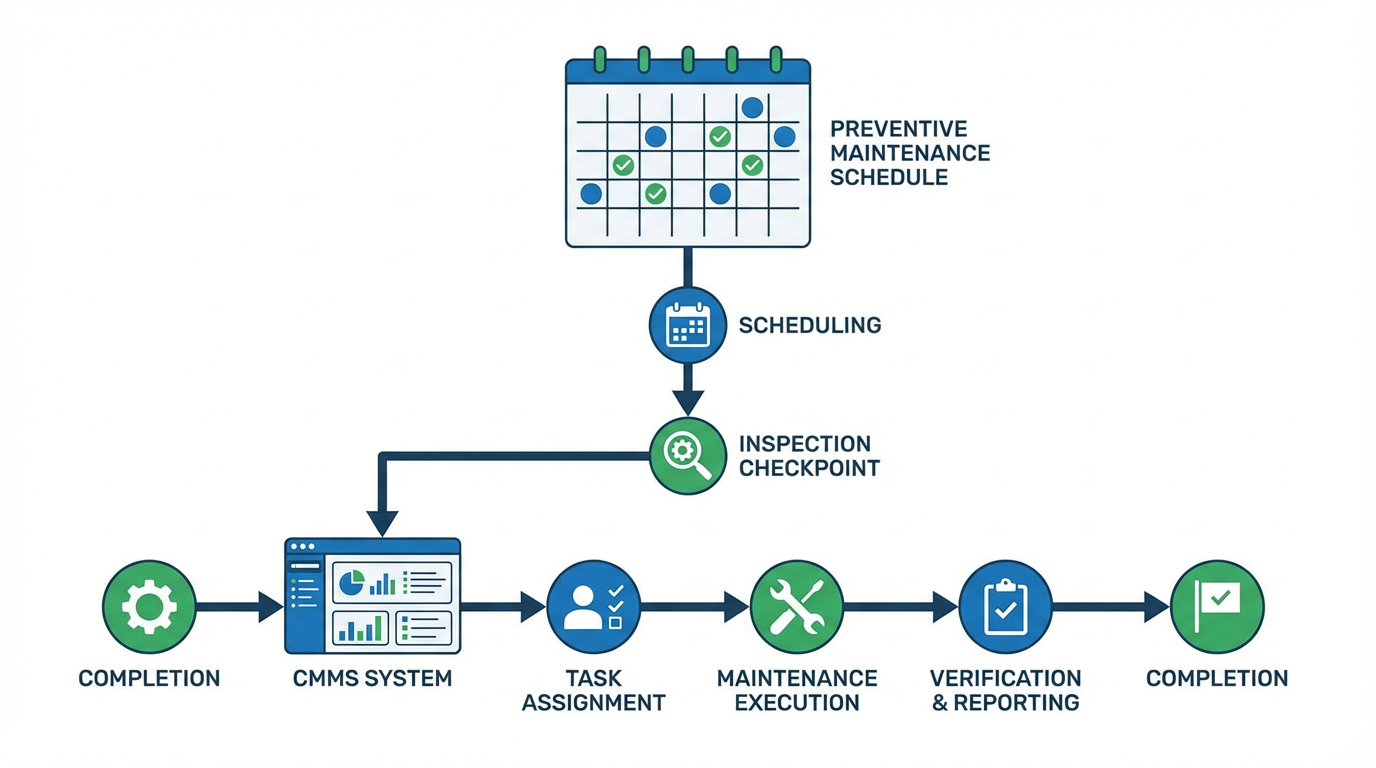

Preventive and predictive maintenance

Almost every authoritative source stresses proactive maintenance. eWorkOrders calls PLC maintenance “essential” to prevent failures, downtime, and costly problems, and lays out a detailed checklist: backing up programs, inspecting connections, checking LEDs and sensors, verifying environmental conditions, and auditing for electromagnetic and radio‑frequency interference. RL Consulting adds periodic inspections of control panels, wiring, and power quality, along with validation of safety systems.

Telstar and Empowered Automation describe how modern PLCs log data and support predictive maintenance, using thresholds and trends to flag issues before they become failures. Automation Electric & Controls notes that newer PLCs even expose predictive analytics that help avoid breakdowns in connected machines.

In practical terms, lifetime support should include a defined inspection and maintenance schedule tuned to your environment. RL Consulting recommends quarterly inspections and annual full reviews in heavy industries like steel or pulp and paper. eWorkOrders suggests more frequent tasks such as dust removal and filter cleaning in harsh or high‑vibration settings, with program backups often done twice per year. Your support provider should help you design and execute that schedule, ideally integrated into your CMMS.

Incident response when something breaks

Automation Electric & Controls describes PLCs as extremely reliable compared with relay systems, but no system is failure‑proof. PEC’s discussion of industrial technical support makes an important point: a single malfunction can stop key operations, so minimizing downtime is central.

For PLC lifetime support, that means clear escalation paths when a line is down, access to people who know your system design, and the ability to diagnose and restore logic and hardware quickly. RL Consulting highlights responsive service at startup and during unexpected issues, supported by good documentation and backups. Eng‑Tips engineers warn that the biggest risk with very old PLCs is often not the hardware but the lack of current program and configuration documentation, which turns a failure into a rebuild project.

A mature support arrangement should make those “bad days” less chaotic by ensuring configuration files, drawings, and known‑good logic are ready to deploy, and by giving you access to experienced engineers who can interpret them under pressure.

Cybersecurity and secure remote access

TXOne’s guide to PLC cybersecurity is blunt: many PLCs were designed before modern security threats and are now exposed on converged networks. Historic attacks like Stuxnet and TRITON targeted specific PLC platforms and safety systems, with potentially catastrophic consequences. The guidance from TXOne and RL Consulting is consistent: industrial control systems need OT‑aware security, not generic office IT controls.

Lifetime PLC support should therefore include:

Design and upkeep of proper network segmentation so control networks are insulated from the general corporate network.

Deployment of OT‑centric firewalls, intrusion detection, and intrusion prevention systems with virtual patching for devices that cannot be taken down often.

Access control based on strong authentication, role‑based privileges, and multi‑factor authentication for administrative actions.

Continuous monitoring for anomalies, with clear procedures for investigation and response.

RL Consulting references ISA/IEC 62443 as the guiding standard for industrial cybersecurity, alongside NFPA 79 for electrical safety. TXOne recommends zero‑trust principles, strong password hygiene, and secure remote access using encrypted tunnels rather than ad hoc connections. Over the life of a PLC system, these controls must evolve as threats and network architectures change, and lifetime support should explicitly include that evolution.

Obsolescence management and upgrade path

MRO Electric and Kurita both stress that technology advancement and vendor product cycles frequently end a PLC’s useful life before the hardware fails. Eng‑Tips contributors describe how some PLC families outlast their manufacturers or are kept alive by long vendor support cycles, but warn that the cost and complexity of replacement skyrocket when documentation and backups are missing.

Lifetime technical support should include structured obsolescence management, not just emergency replacement. That means:

Tracking vendor life‑cycle notices, end‑of‑sale and end‑of‑support dates for your specific CPUs, communication modules, and I/O.

Developing a spares and replacement strategy early enough that you can still buy supported hardware.

Planning migrations in stages, replacing or upgrading control panels, HMIs, and PLCs while the process keeps running.

Kurita emphasizes that upgrades are often more practical and cost‑effective than full equipment replacement, especially when the provider understands the original system design. RL Consulting calls this “future readiness” and recommends using maintenance reviews to spot components and software approaching obsolescence so you can plan retrofits instead of reacting to sudden failures.

Training, documentation, and knowledge transfer

Both NTT Training and RL Consulting argue that training is not optional if you want long‑term stability. NTT notes that relying entirely on external contractors for PLC troubleshooting raises costs and delays repairs, whereas trained in‑house staff can respond immediately to many issues. RL Consulting’s clients value clear as‑built drawings, updated programming notes, and hands‑on training so operators and technicians can handle first‑line troubleshooting.

Lifetime support should specify how documentation will be created and maintained and what training is included. That might involve:

Standardized code and naming conventions aligned with IEC 61131‑3.

Up‑to‑date wiring diagrams and panel layouts built to UL 508A and NFPA 79 requirements, as Kurita stresses.

Operator and maintenance training focused on the actual system installed in your plant rather than generic lab setups.

Structured backup and change‑management procedures that your in‑house team understands and follows.

When documentation and training are treated as first‑class deliverables within lifetime support, you avoid the slow erosion of knowledge that makes a decade‑old PLC system feel like a black box nobody wants to touch.

What this looks like in practice

Bringing these elements together, a well‑designed lifetime support program for PLC systems often resembles the pattern in this table.

| Support domain | What “lifetime PLC support” should look like |

|---|---|

| Maintenance | Scheduled inspections, cleaning, calibration, and program checks tied to CMMS |

| Incident response | Fast access to engineers, known‑good backups, clear procedures for failures |

| Cybersecurity | Segmented networks, OT‑aware firewalls, monitoring, and access control |

| Obsolescence management | Lifecycle tracking, spares strategy, staged migrations and upgrade planning |

| Documentation and training | Living documentation, operator and technician training, change‑management process |

The exact mix and depth will vary by plant size and industry, but the underlying themes are consistent across sources from eWorkOrders, RL Consulting, TXOne, Kurita, and others.

Pros and Cons of Lifetime PLC Technical Support Agreements

From a plant manager’s perspective, lifetime support looks attractive, but it is worth weighing the trade‑offs with clear eyes.

On the positive side, you gain continuity. Instead of repeatedly shopping projects to low‑bid contractors, you work with a partner that knows your installed base, your standards, and your production realities. RL Consulting describes clients that value this long‑term relationship because it brings consistent system design, faster commissioning, and smoother maintenance. A lifetime support framework also aligns incentives toward reliability and total cost of ownership rather than short‑term project margins. When the same partner is responsible for maintaining what they install, they are more likely to design around clean panels, proper grounding, and clear code, as Kurita and AutomationDirect recommend.

Budget predictability is another benefit. MRO Electric’s discussion of lifecycle planning suggests that proactive upgrades and standardized platforms reduce surprise expenses. A lifetime support agreement that includes lifecycle reviews, spares planning, and modernization roadmaps helps you avoid sudden, all‑at‑once replacement shocks when a vendor declares a product line obsolete.

There are downsides. The most obvious is long‑term cost and potential vendor lock‑in. If the support scope is poorly defined or the provider underperforms, it can be hard to change course quickly. You also risk a false sense of security if the words “lifetime support” lead leadership to assume they no longer need internal PLC skills or a disciplined maintenance culture. NTT and eWorkOrders both make it clear that internal capabilities and preventive maintenance remain essential even with strong external support.

Finally, an overly generic lifetime support package can misalign with your actual risk profile. A lightly used test system and a critical continuous process plant deserve different inspection intervals, spares policies, and cybersecurity controls. If the agreement does not flex for those realities, you may pay for coverage you do not need in some areas and remain exposed in others.

The answer is not to avoid lifetime support but to scope it carefully and treat it as a partnership, not insurance.

Making Lifetime Support Work in Your Plant

In my experience working with plants in pulp and paper, steel, automotive, food, and water treatment, the sites that truly benefit from lifetime PLC support do a few practical things from the start.

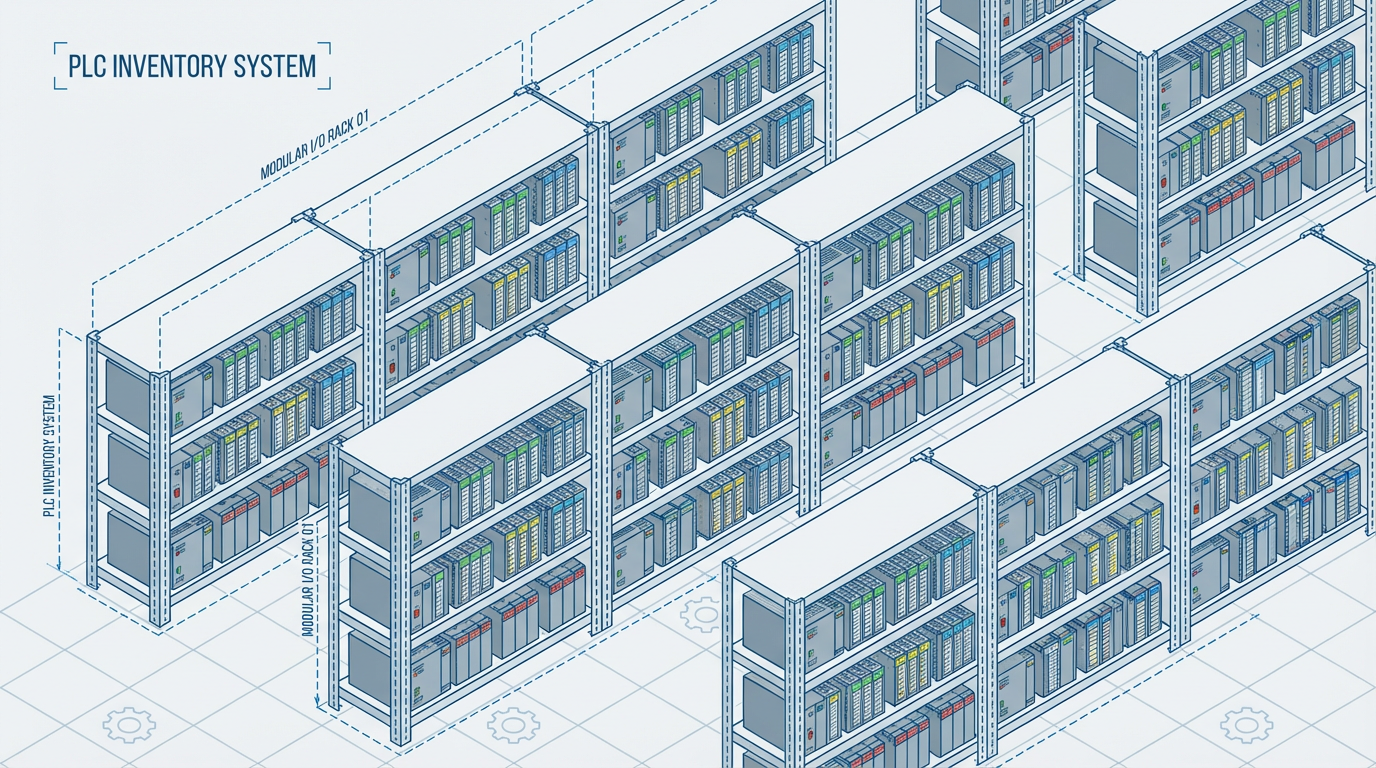

First, they know what they own. Patrion and AutomationDirect suggest starting any PLC project by mapping field devices and I/O. For lifetime support, that idea extends to a living inventory of CPUs, firmware versions, I/O modules, network devices, and critical field instruments, with location and function clearly documented. Eng‑Tips engineers warn how painful replacements become when old programs and configurations cannot be found; a good inventory and document set is the antidote.

Second, they standardize intentionally. MRO Electric recommends standardizing PLC hardware and software platforms across a facility to simplify spares, training, and maintenance. RL Consulting echoes this in its focus on reliable, future‑ready system design. Standard PLC families, common programming conventions, and consistent panel construction make lifetime support far more effective because every new project strengthens the same knowledge base.

Third, they align maintenance schedules with real conditions. eWorkOrders points out that maintenance frequency should reflect application and environment. A clean, temperature‑controlled room with low vibration does not need the same inspection cadence as a hot, dusty area with heavy mechanical stress. RL Consulting’s quarterly and annual review pattern for heavy industries is a good reference point, but the right schedule must be tuned to your plant, with support engineers and your maintenance planners looking at actual error histories and failure trends.

Fourth, they integrate security and remote access from the beginning. TXOne warns that retrofitting security onto a wide‑open OT network is hard and risky. Lifetime PLC support should therefore include network and security design early in the relationship: segmentation, firewall placement, remote access patterns, and monitoring. RL Consulting’s use of ISA/IEC 62443 as a design guide is a practical starting point.

Fifth, they treat training as an ongoing process, not a one‑time class at commissioning. NTT and RL Consulting both argue for building internal PLC literacy so operators and maintenance staff can spot issues early. Lifetime support should specify refresher training plans, coaching during maintenance visits, and structured involvement of your internal team in logic reviews and upgrades. Over time, your people become more capable partners rather than passive consumers of support.

Finally, they plan for the next generation of controls before the current one fails. Kurita and MRO Electric both emphasize proactive planning for control system upgrades. That might mean piloting a new PLC family on a small line, then gradually migrating critical systems, or adding remote I/O and updated HMIs while keeping the original CPU in place temporarily. Lifetime support is the natural home for that planning because it blends intimate knowledge of your current system with awareness of vendor roadmaps and industry standards.

Short FAQ on Lifetime PLC Technical Support

How long do PLCs actually last, and what does that mean for “lifetime” support?

MRO Electric suggests a typical PLC operational lifespan in the range of 10 to 20 years under normal conditions, with some units running over 30 years when they are kept clean and cool and maintained well. Eng‑Tips engineers report similar experiences, noting that I/O modules and field devices usually fail before CPUs. Lifetime support, in practice, means covering that full span plus the migration work into whatever platform replaces the original PLC, rather than a literal promise to support hardware indefinitely.

Do I still need in‑house PLC skills if I have lifetime technical support?

Every credible source that discusses training says yes. NTT stresses that without internal PLC understanding, you become dependent on expensive external experts and may wait longer for critical fixes. RL Consulting’s clients value training and documentation because it lets their teams handle first‑line troubleshooting and routine checks. Lifetime support should complement, not replace, in‑house competence.

Can legacy PLCs still be covered under a lifetime support model?

They can, but the nature of support changes as hardware moves into late life. Eng‑Tips warns that with very old PLCs, the main risk is often missing documentation and obsolete parts. Kurita notes that upgrade projects can be cost‑effective even when mechanical systems remain sound. A realistic lifetime support plan for legacy PLCs will include a strong focus on backups, documentation reconstruction where needed, spare parts strategy, and staged migration to newer hardware while the plant keeps running.

How does cybersecurity fit into lifetime PLC support?

TXOne argues that PLC cybersecurity is now as critical as physical reliability because attacks can cause shutdowns and safety incidents. RL Consulting folds cybersecurity into its maintenance standards using ISA/IEC 62443. Over the life of a PLC system, networks will change, remote access needs will evolve, and threats will grow more sophisticated. Lifetime support should therefore include ongoing security assessments, network segmentation, OT‑aware monitoring, and updates to access control policies alongside traditional maintenance.

Closing

Over the years, I have seen PLC systems quietly serve as the backbone of plants long after the original project team has moved on. The sites that sleep best are the ones that treat lifetime PLC support not as a line item, but as a long‑term partnership that blends maintenance, security, documentation, and modernization into one continuous process. If you design your support that way from day one, your PLCs can do what they do best: run, day after day, without drama, while you keep your attention on production and improvement instead of firefighting.

References

- https://www.patrion.net/en/blog/what-is-plc-and-its-use-cases

- https://www.esc7.net/apps/news/article/1749725

- https://www.plctalk.net/forums/threads/life-span-of-a-plc.103625/

- https://www.empoweredautomation.com/automation-plc-explained-functions-and-benefits

- https://www.seifert.com/are-plcs-necessary-in-todays-automation-environment

- https://support.automationdirect.com/docs/whatisaplc.html

- https://automationelectric.com/6-most-important-reasons-for-using-plc-controllers/

- https://www.cloud.studio/plc-features-and-benefits/?srsltid=AfmBOorgjnOgZSMLDe6Ao6CYnWwr5dXGOk6hd7aN_C73X4icF0gRYl-2

- https://www.kuritaamerica.com/the-splash/is-your-control-system-built-to-last

- https://theeducationhub.org.nz/practices-of-effective-professional-learning-communities/

Keep your system in play!

Related Products

-

Manufacturer: Motorola VME

-

Manufacturer: Motorola VME

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment