-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Warranty Terms for Pre-Owned Servo Drives: A Veteran Integrator's Guide

Why Warranty on a Used Servo Drive Is More Than a Checkbox

In a modern plant, servo systems sit right on the critical path. Drives control the torque, speed, and position that keep robots, CNC axes, packaging lines, and conveyors synchronized. When a drive dies, production stops. One servo repair provider notes that a failed servo system can instantly create thousands of dollars in lost output, especially in high-throughput manufacturing. That is the context in which you should read every line of a warranty on a pre-owned drive.

As a systems integrator, I see three common motivations for buying used drives. One is keeping an older line running when the original part is obsolete. Another is shaving capital cost on a low-risk application. The third is emergency replacement when a critical drive fails and lead times on new units are measured in weeks. In all three cases, the warranty terms determine whether that used drive is a safe bridge or a hidden liability. Price is visible on the quote. Warranty quality is buried in the small print.

What “Warranty” Really Means in Industrial Motion

A warranty in this context is not a friendly slogan; it is a legal commitment. One integrated servo motor supplier explains it plainly as a promise that the product will perform as advertised and be free from defects for a specified period. Most serious industrial suppliers limit that promise to defects in materials and workmanship. They do not guarantee that the product will survive abuse, misapplication, or poor maintenance.

Servo-related manufacturers use different language, but the pattern is consistent. A gearbox and geared-motor manufacturer such as STOBER Drives describes its warranty as coverage for defects in material and workmanship, with the remedy at STOBER’s option being repair or replacement of the defective product. A servo manufacturer like MKS Servo offers a one-year warranty from the purchase date at an authorized dealer, again focused on defects and again with conditions attached. An integrated servo supplier described by Sarah Lee provides a standard two-year warranty on its motors, covering defects and explicitly including parts, labor, and shipping when a covered failure occurs.

The critical implication is that warranty is not insurance on everything that can go wrong with a servo drive over its life. It is a narrow commitment around how the product was built, not how it has been used or abused. That distinction becomes even more important when the hardware is on its second or third owner.

Duration and Start Date: Looking Beyond the Big Number

The first number everyone looks at is the warranty length. On new integrated servo motors, Sarah Lee notes that many manufacturers offer one to three years of coverage, with some high-end models pushing out to five years or more. Her own company standardizes on two years across its integrated servo line. Teknic’s Hudson servo motors carry a three-year warranty that starts when the motor enters service, with up to six extra months allowed for storage before installation. That “in-service start plus storage grace” is a good example of a manufacturer aligning warranty reality with real project timelines, where motors may sit on a shelf before commissioning.

Mechanical components tied to servo applications can stretch further. STOBER Drives publishes warranty periods up to five years for certain ServoFit products in single-shift service, with shorter periods for multi-shift operation. Their MGS products are covered for three years in single-shift duty and eighteen months in multiple shifts, while ComTrac products sit at two years or twelve months depending on duty cycle. Normal wear items such as oil seals and bearings have shorter durations. The headline lesson is that “five-year warranty” in a brochure may translate to a shorter period if you run around the clock.

On the pre-owned side, the picture looks very different. Motor Systems Inc. points out that legacy servo drives sold online are often ten to twenty years old, and they back their own reconditioned drives with a one-year guarantee after thorough inspection, component replacement, and testing on factory-issued fixtures. A used Keyence servo motor listed on a marketplace like eBay may also advertise a one-year warranty, but that is a seller promise with unknown depth, not an OEM-backed commitment. Duration alone does not tell you much. You need to know who is standing behind that number and what they are really promising to do when things go wrong.

Coverage, Remedies, and Hidden Costs

Once you get past the duration, you need to understand what the warranty actually covers and what remedy you can expect. Sarah Lee’s integrated servo motor example is generous by industrial standards: a two-year warranty covering all defects in materials and workmanship, with repair or replacement at no charge including parts, labor, and shipping. That kind of cradle-to-grave coverage minimizes surprise costs when a legitimate defect surfaces.

By contrast, STOBER Drives’ terms illustrate a more traditional industrial pattern. Their sole warranty remedy is, at the company’s option, repair or replacement of defective product, shipped F.O.B. their facility, with freight prepaid by the manufacturer. Customers must notify STOBER in writing within the warranty period and within five days after discovery of the defect, provide satisfactory evidence, and comply with inspection and usage requirements. The company disclaims all other express or implied warranties, including merchantability and fitness for a particular purpose, and explicitly limits liability to that repair-or-replace option. There is no promise to cover your downtime, overtime labor, or missed orders.

MKS Servo adds another nuance with its Dead on Arrival concept. Their products are not considered DOA once installed. DOA status applies only when a product fails during pre-installation testing and is flagged within seven days of purchase via a dedicated DOA form. If a returned servo does not meet DOA conditions, it shifts into the standard RMA workflow under the one-year warranty, with the usual requirements for completed RMA forms, proof of purchase, and serial numbers. For out-of-warranty products, MKS charges test and maintenance fees plus parts, and repaired units do not carry a new warranty term; they keep whatever remained, if anything, of the original.

STOBER also charges non-warranty inspection fees at tiered levels for returned units, ranging from a modest evaluation fee for visual inspection up to more significant charges for detailed root-cause analysis involving disassembly and laboratory work. After repair, their policy states that the original unit’s warranty continues, and no new warranty is issued on the repaired unit. That is a crucial detail when you consider sending a borderline, pre-owned drive back to an OEM or component manufacturer. You may pay to have it opened and evaluated only to discover that there is no coverage and the unit is effectively scrap.

For pre-owned servo drives, these examples highlight why you cannot treat “one-year warranty” as a commodity attribute. You must understand what remedy is actually being offered, which costs are covered, what procedural hoops you must jump through, and whether any fresh warranty clock will start after a repair.

Exclusions, Misuse, and When a Warranty Disappears

Exclusions are where many warranty claims go to die. Manufacturers are explicit about what they will not cover, and pre-owned hardware is far more likely to have lived in those gray areas.

MKS Servo gives a representative list. Free warranty service does not apply when defects arise from natural disasters, normal wear and tear, inappropriate usage or installation, water immersion, gear abrasion or stripping, or motor or PCB burning. Warranty is void if products are disassembled or repaired by unauthorized personnel, if the PASS sticker (warranty label) is altered or missing, if the serial number or power output is modified, or if the product is self-modified or used with non-MKS components. Second-hand products are explicitly excluded from coverage, and only products sold by authorized agents qualify.

STOBER Drives takes a similar stance. Their warranty excludes normal wear and tear, routine replacement parts, misuse, misapplication, negligence, improper maintenance, improper installation, unauthorized modification or repair, incompatible systems or vibration problems, and loads exceeding the published capacity. They also state that third-party components installed in STOBER products carry only the third party’s original warranty, not STOBER’s.

Now overlay those exclusions on real-world servo drive failure modes. A widely cited servo drive maintenance guide lists overheating from blocked airflow or failed fans, contamination with dust, oil mist, or moisture, power surges and brownouts, capacitor aging, loose or oxidized connectors, and software or parameter errors as common causes of failure. Very little of that looks like “defect in materials and workmanship.” Most of it looks like environment, maintenance, and application. If a drive spends ten years in a hot, dusty cabinet with fans clogged and filters missing, a capacitor failure is more likely to be viewed as normal wear under harsh conditions than as a warrantable defect.

With pre-owned drives, you usually have no visibility into that history. You do not know how many years of twenty-four hour service they have endured, how often they were overdrove on current, or whether they spent time in a washdown area without proper sealing. That is why, in practice, exclusion language matters more for pre-owned than for new equipment. The probability that the next failure will be traceable to environment and misuse, not OEM defect, is simply higher.

Transferability and the Second-Hand Problem

Perhaps the most important question for pre-owned buyers is whether any OEM warranty is still valid at all. Several published policies suggest the answer is often no.

STOBER Drives defines the Customer as the distributor, resale dealer, original equipment manufacturer, or first end-user purchasing STOBER products, and states that the warranty is expressly intended only for this Customer and is non-transferable. Third parties cannot assert warranty claims against STOBER. That means that if you buy a gearbox or geared motor that is only a year old from another plant, you are a third party with no direct warranty rights under those terms, even if there is nominal time left on the clock.

MKS Servo is even more explicit in the servo space. Their warranty applies only to products sold by authorized agents, and second-hand products are excluded. Once a servo passes through an unauthorized resale channel, the MKS warranty is effectively gone, regardless of age.

These examples do not prove that every servo or drive manufacturer follows the same model. They do show that you cannot assume OEM coverage follows the hardware. On the contrary, you should treat OEM warranty as attached to the original transaction and the original customer unless the policy clearly says otherwise. For pre-owned drives, practically speaking, your only enforceable warranty is whatever the current seller is prepared to put in writing.

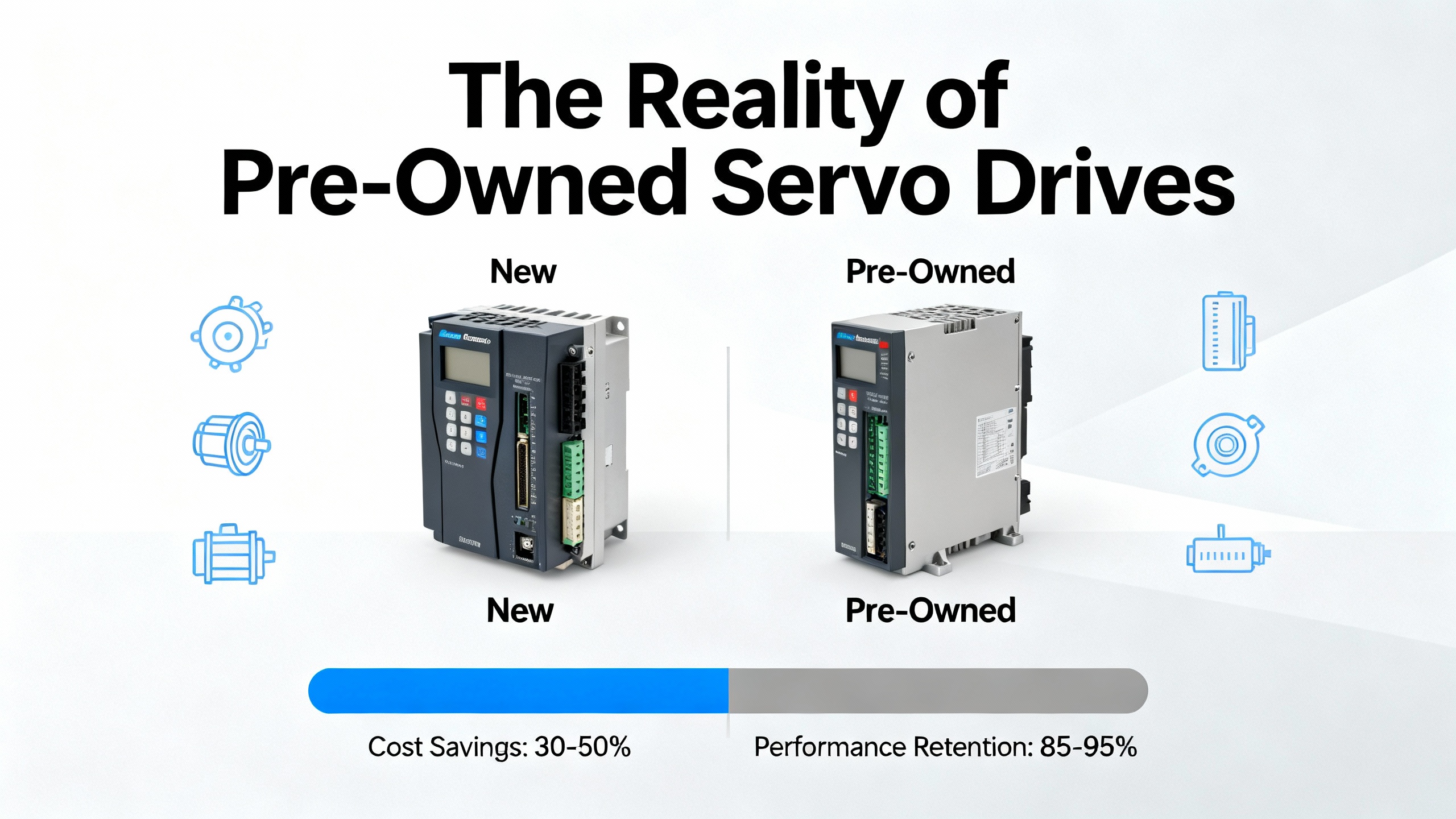

The Reality of Pre-Owned Servo Drives

Used drives sold through auctions and general marketplaces carry specific risks that are well documented by service providers who clean up the mess afterward. Motor Systems Inc. reports that legacy servo drives offered online are often ten to twenty years old and typically have seen little or no preventive maintenance. At the same time, a servo drive maintenance guide puts normal drive lifespan in the eight to fifteen year range under proper conditions, with better environments and maintenance pushing toward the high end of that range. If you are staring at a twenty-year-old drive, you are well past that nominal envelope.

Motor Systems notes failed capacitors as a very common problem in internet-purchased drives. Those failures are often accompanied by damaged circuit boards, and the repair costs can be significant. Once you factor in the cost of repairing the “bargain” and the production downtime while the machine is out of service, the total cost of that used drive can exceed the price of a professionally reconditioned unit. Their conclusion is that a single unexpected repair on an online-purchased drive can quickly turn a low price into a poor overall investment.

From my side of the fence, these observations line up with what we see in plants. The cheap auction drive often arrives with no verifiable maintenance history, no recent testing report, and only the vaguest of warranties from the seller. You may get lucky, but you are betting your line on that luck.

Professionally Reconditioned Drives with Written Guarantees

There is a very different class of “used” drive: the professionally reconditioned unit backed by a structured process and a formal guarantee. Motor Systems Inc. describes an in-house inventory of reconditioned servo drives that have undergone thorough inspections by factory-trained technicians. These drives are retrofitted with new components and tested on factory-issued test fixtures to verify reliability and performance under demanding conditions. MSI backs those units with a one-year guarantee.

Other repair and supply specialists show similar patterns. Neutronic Technologies, for example, specializes in repair, maintenance, and supply of servo motors, drives, and complete motion control systems. Their workshop handles both mechanical and electronic work under one roof, rewinds stator windings, replaces bearings, calibrates encoders, and tests under simulated loads. They emphasize preventive maintenance, scheduled inspections, and rapid parts supply. Service quality is underpinned by ISO 9001 quality management systems, SafeContractor accreditation, and recognition as a finalist in industry awards for service excellence. While their published description focuses on repair quality rather than warranty duration, they clearly position repaired and refurbished units as tested and guaranteed for safe long-term use.

Perfection Servo tells a similar story in the wider industrial repair space. They highlight decades of experience and position their services as “expert repairs that offer bottom-line protection.” Combined, these examples illustrate what you should expect from a reputable reconditioning partner: component-level refurbishment, documented testing, quality certifications, and a clearly stated guarantee.

When you compare a one-year guarantee from a specialist that tears a drive down, replaces aging components, and validates performance to a one-year “warranty” from an anonymous online seller, you are looking at very different risk profiles. The text may sound similar, but the underlying probability of early failure is not.

OEM Policies and Repairs Still Matter

Even when you are dealing with pre-owned drives, OEM policies for motors, gearboxes, and associated components remain relevant. Teknic’s Hudson servo motors, for example, are UL and CE certified and are subjected to extensive testing, including stress screening beyond published specifications, before shipment. They carry a three-year warranty that starts when the motor enters service, with an additional allowance for up to six months of storage before installation. That kind of long, clearly defined coverage on new motors reduces the incentive to take risks on unknown second-hand units for critical axes.

Sarah Lee’s integrated servo supplier underscores that, in the broader market, typical warranty periods for integrated servo motors range from one to three years, with some high-end models extending to five years or more. Her company standardizes on two-year coverage backed by comprehensive support, including an easy claim process and proactive technical assistance. This shows how new product warranties can be used as competitive differentiation and risk management tools, not just legal boilerplate.

On the mechanical side, STOBER’s terms illustrate another important principle: repairs do not always create a new warranty period. After their products are repaired, the original unit’s warranty continues, and no new warranty is issued on the repaired unit. They also apply structured non-warranty inspection fees if a returned item is not found to be covered. For pre-owned drives and gear, that means you should not assume an OEM repair will restart the clock. Often, you are merely preserving whatever time remained for the original customer, and if you are a second-hand buyer, you may not even have that.

Key Warranty Clauses to Check Before You Buy a Used Drive

When a client puts a pre-owned drive on my desk and asks whether it is a safe purchase, I focus on a small set of questions about the warranty document.

One question is how long the coverage really lasts, starting from which date, and under which duty assumptions. Examples from the market show how different this can be. Integrated servo motors from the supplier described by Sarah Lee typically carry two-year coverage, and she notes that competitors often range from one to three years, with some high-end products at five years or more. Teknic’s Hudson servo motors provide three-year coverage starting at service entry plus up to six months storage. STOBER Drives publishes multi-year warranties for gearboxes and geared motors, varying from two to five years depending on product family and whether the application runs single or multiple shifts. Motor Systems Inc. offers a one-year guarantee on reconditioned servo drives, after replacing critical components and testing, while a used Keyence servo motor sold on a marketplace is also advertised with a one-year warranty from the seller. MKS Servo offers a one-year warranty on servos purchased from authorized dealers but excludes second-hand products entirely. These examples show that you must align warranty length with product age, expected remaining life, and the rigor of any reconditioning that has been done.

Another question is what the warranty actually covers in terms of costs. Sarah Lee’s integrated servo motors are covered for defects in materials and workmanship, with parts, labor, and shipping included when the company repairs or replaces a defective unit during the two-year period. STOBER’s terms, by contrast, focus on repair or replacement of the defective product shipped from their facility, with freight prepaid, but explicitly exclude consequential damages or broader liability. MKS requires that customers submit DOA or RMA forms, return products in original packaging with proof of purchase and serial numbers, and accept that out-of-warranty work will incur test, maintenance, and parts fees, with no new warranty on repaired out-of-warranty products. For pre-owned drives, you need the seller to state clearly whether their warranty covers only parts, or also bench labor, field labor, and freight in both directions.

A third question is what exclusions and voiding conditions apply. The lists from MKS and STOBER make it clear that normal wear, misuse, improper installation, unauthorized repairs, and operation outside published specifications can all disqualify a claim. Given what servo drive failure analyses tell us about overheating, contamination, power quality issues, and parameter mistakes, you should assume many failures on older drives will be argued as non-warrantable unless the seller has explicitly committed otherwise.

A fourth question concerns who is actually allowed to make a claim. STOBER restricts warranty rights to the original Customer and declares the warranty non-transferable. MKS restricts coverage to products sold by authorized agents and excludes second-hand products. In practical terms, if you are buying a used drive or gearbox from a broker, you should work on the assumption that any OEM warranty is gone and that all you have is the seller’s own warranty.

Finally, there is the question of how the claim process works and what friction you will encounter. MKS requires DOA forms within seven days for pre-installation failures and detailed RMA documentation afterward. STOBER expects written notice within the warranty period and within five days of discovering a defect, along with sufficient evidence and compliance with inspection procedures. Both companies charge structured fees for non-warranty evaluations and hold returned products for limited periods before treating them as abandoned. For a used drive, you need to know whether the seller will shield you from those OEM processes by handling claims on your behalf or whether you will be navigating them directly without full documentation.

To illustrate how varied warranty regimes can be, it is useful to look at a concise comparison.

| Scenario or product type | Example from published terms | Observed warranty characteristics relevant to pre-owned buyers |

|---|---|---|

| New integrated servo motor | Integrated servo supplier described by Sarah Lee | Market range typically one to three years, with some high-end offerings up to five years; this supplier uses a two-year term with parts, labor, and shipping included for covered defects. |

| New servo motor family for OEM use | Teknic Hudson servo motors | Three-year warranty that starts when the motor enters service, with up to six months allowed for storage before installation. |

| Reconditioned servo drive | Motor Systems Inc. reconditioned drives | One-year guarantee following component replacement and testing on factory-issued fixtures, aimed at legacy and obsolete drives. |

| Precision gearboxes and geared motors | STOBER Drives ServoFit, MGS, ComTrac, and geared motor product lines | Warranty durations ranging from two to five years in single-shift duty and shorter periods in multi-shift duty; coverage limited to original Customer and non-transferable. |

| Servos with DOA and second-hand restrictions | MKS Servo servos | One-year warranty from purchase at an authorized dealer; limited DOA exchange within seven days before installation; second-hand products excluded. |

| Used servo motor sold via general marketplace | Example listing for a used Keyence servo motor on an auction-style platform | Advertised as tested with a one-year warranty from the seller; underlying product age, reconditioning process, and warranty scope are unspecified. |

| High-end integrated servo offerings in the wider market | Summary observation from Sarah Lee’s integrated servo warranty article | Some high-end integrated servo motors offer warranties of up to five years or more, often used as competitive differentiators. |

These examples are not an exhaustive catalog, but they highlight just how wide the spread is between different new, reconditioned, and second-hand offers. They also underline why you must read the actual terms rather than relying on the word “warranty” by itself.

Using Warranty Terms to Drive a Sound Business Decision

A warranty is not a substitute for engineering judgment. It is one lever in a broader risk calculation that should include the age of the hardware, the criticality of the axis, the environment, and your maintenance practices.

A servo drive maintenance guide points out that drives typically last eight to fifteen years under normal conditions, with cleaner environments and good preventive practices pushing toward the upper end. At the same time, Motor Systems Inc. observes that many drives sold online are ten to twenty years old and have received little preventive maintenance. Combine those two facts, and it becomes clear that a twenty-year-old drive with a one-year seller warranty is not equivalent to a five-year-old drive with a one-year guarantee from a reconditioning house that has replaced capacitors and stress-tested the unit.

Neutronic Technologies’ example shows how professional repair and supply operations build a different value proposition. They use vibration and thermal analysis, insulation testing, encoder calibration, and simulated loads to validate performance. They also emphasize 24/7 emergency response and ISO 9001 quality systems. While that does not eliminate the possibility of failure, it materially reduces risk compared with a unit of unknown origin pulled from an auction pallet.

As a practical approach, I encourage plant teams to start by quantifying the cost of downtime on the machine the drive will support. If an hour of lost production costs more than the price difference between a reconditioned drive with a documented one-year guarantee and a random used drive with vague assurances, the economic choice is often obvious. For non-critical test stands or training rigs, you may accept more risk. For a bottleneck line, it rarely makes sense to gamble.

FAQ: Common Questions on Pre-Owned Servo Drive Warranties

If I buy a used servo drive, can the original OEM warranty still protect me?

Sometimes, but you should not assume it. STOBER Drives explicitly restricts its warranty to the original Customer and marks it as non-transferable. MKS Servo limits its warranty to products sold by authorized agents and excludes second-hand products. Unless an OEM’s written policy clearly allows warranty transfer, the safer assumption is that OEM coverage ends with the first sale, and your protection on used drives comes solely from the current seller.

Is a one-year seller warranty enough on an older drive?

It depends on the underlying condition of the drive and how that warranty is backed. Motor Systems Inc. reports that many online drives are ten to twenty years old, with common issues like failed capacitors and damaged boards, and that repairs plus downtime can easily outweigh the initial bargain price. A one-year guarantee from a specialist who has replaced aging components and tested the unit is more meaningful than the same duration from a seller who has simply powered it up. Age relative to the typical eight to fifteen year life window for servo drives also matters. A one-year warranty on a five-year-old reconditioned drive is a different proposition than a one-year warranty on a twenty-year-old unit with no refurbishment.

How should I document a used-drive purchase for warranty purposes?

Look at how serious suppliers handle documentation and mirror those expectations. MKS Servo requires completed DOA or RMA forms, original packaging, purchase invoices showing serial numbers, and clear identification of the problem. STOBER expects written notification within tight time windows and evidence of the defect. For pre-owned drives, you should insist that the seller provides serial numbers, prior repair records if available, and a written warranty statement that spells out coverage, duration, and process. Store those documents where your maintenance and purchasing teams can retrieve them quickly when a failure occurs.

Closing Thoughts

Pre-owned servo drives can absolutely be part of a reliable, cost-effective control strategy, but only when you combine rigorous technical evaluation with equally rigorous scrutiny of the warranty behind them. When you read terms from companies like Teknic, STOBER, Motor Systems Inc., MKS Servo, and serious repair houses such as Neutronic Technologies, you see how much thought reputable players put into aligning warranty with real-world reliability. If you apply that same discipline as a buyer, you will treat warranties not as marketing badges, but as engineered risk controls that either support your project or quietly undermine it.

References

- https://static.nhtsa.gov/odi/tsbs/2021/MC-10187277-9999.pdf

- https://mks-servo.com/After-Service

- https://www.perfectionservo.com/

- https://theservogroup.com/

- https://www.ebay.com/itm/166767593311

- https://www.mitchell-electronics.com/7-requirements-for-an-in-house-servo-motor-repair-environment/

- https://neutronictechnologies.com/keeping-industry-moving-your-trusted-partner-in-servo-motor-repair-drive-diagnostics-system-maintenance-supply/?srsltid=AfmBOoo5IleUk1kt1EpK2KcIoN9D200IB9Ouv77vp1U_NvExIcBn5Duk

- https://www.rotationstage.com/blog/what-is-the-warranty-period-of-an-integrated-servo-motor-873173.html

- https://servoproductsco.com/html/service_centers.html

- https://www.stober.com/terms-of-sale/

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment