-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Refurbished PLC Warranty Terms: What Buyers Need to Know

In most plants I work with, nobody loses sleep over the catalog price of a PLC module. They lose sleep over the cost of an unplanned shutdown. Refurbished PLCs, HMIs, and drives have become a standard way to keep legacy systems running and control costs, but they also introduce a new kind of risk: you are relying on a third party to stand behind hardware that has already lived one life.

That risk is managed—or mishandled—in the warranty.

Across industrial and marine automation, reputable refurbishers emphasize rigorous testing and strong warranties. Industrial Automation Co. reports that well-refurbished hardware can save about thirty to seventy percent versus new OEM parts while still carrying a two‑year warranty, which they describe as roughly double the common industry standard for refurbished components. Aeliya Marine Tech frames similar savings but stresses the importance of documented tests and clear return terms. At the same time, other suppliers offer three‑month warranties, or “as‑is” sales with no coverage at all.

If you are an engineer, maintenance manager, or project lead, you do not need a law degree to navigate this. You do need to understand what refurbished PLC warranties typically look like, what they actually cover, and how to compare offers in a way that aligns with your production risk.

This article walks through that, from the perspective of someone who has had to keep real lines running with refurbished hardware in the mix.

What “Refurbished” Really Means For PLCs

In industrial automation, refurbished is not just a polite word for used. Multiple specialist suppliers make the same distinction.

Industrial Automation Co. defines “used” parts as modules pulled from service and sold as‑is: no testing, no warranty, unknown remaining life. By contrast, refurbished PLCs, HMIs, and VFDs are professionally cleaned, inspected, repaired to OEM specifications, and fully tested under operational load before shipment. Aeliya Marine Tech describes similar processes that include replacing defective components, cleaning, updating firmware, calibrating analog channels, and functional testing under realistic operating conditions, all with the aim of meeting original performance and safety standards.

Qualitrol describes its remanufactured PLC parts as “like‑new” and emphasizes that its technicians are certified to electronics rework standards, using OEM components or approved equivalents. Their remanufactured PLCs are backed by a two‑year warranty and typically cost about half of the manufacturer’s suggested retail price.

The important point is that a proper refurbishment process reduces technical risk, and the warranty is one way the refurbisher signals confidence in that process. When you see a module labeled simply “used,” sold with no warranty or testing documentation, you are not just gambling on the hardware; you are accepting that any failure is entirely your problem.

Who Actually Backs The Warranty?

With new PLC hardware, the OEM often provides a factory warranty. With refurbished hardware, that is rarely the case.

Apogee, an audio equipment manufacturer, provides a clear example. Its factory warranty applies only to new products purchased from authorized dealers. Refurbished or previously owned units sold by dealers are treated as out of factory warranty; any coverage is entirely at the dealer’s discretion. Only refurbished units sold directly by Apogee’s own web store carry the factory warranty.

The same pattern shows up in industrial automation. Suppliers such as PLC Exchange, PLC2Day, PLC Ltd, PLC Parts Solution, and Qualitrol explicitly state that warranties on refurbished or “new/open box” items are issued by them, not by the original manufacturer. AutomationDirect’s general warranty terms also distinguish between products they brand and third‑party items they resell, where coverage can fall back to the original manufacturer’s own policy.

For you as a buyer, this means the real questions are simple. Who will you call when a refurbished PLC fails? What exactly have they promised to do? And for how long?

The answer is almost always “the refurbisher, under their limited warranty,” not the PLC OEM.

A useful way to think about it is summarized in the following example comparison.

| Hardware source type | Who backs the warranty | Typical duration examples |

|---|---|---|

| New PLCs from OEM or major distributor | OEM or authorized distributor | Around 12 months is common, sometimes more, per Qviro |

| OEM‑refurbished units (where available) | OEM | Often similar to new; Qviro notes cases of one‑year cover |

| Independent refurbished PLC suppliers | The refurbisher (their own limited warranty) | Three months to two years in real policies |

| Pure “used” or “as‑is” secondary market | Nobody | No warranty; all risk is on the buyer |

Once you accept that your counterpart is the refurbisher, their warranty language stops being fine print and becomes a central part of your risk model.

How Long Do Refurbished PLC Warranties Last?

Actual terms vary widely, but there is enough published data to sketch real-world patterns.

PLC Exchange states that all “factory sealed” and “new/open box” products they sell include a free one‑year warranty. The warranty is issued directly by PLC Exchange, not the original manufacturer, and starts on the date the carrier confirms delivery or, if that is not available, three business days after the order date. The “warranty period” is defined as three hundred sixty‑five calendar days from that start.

PLC2Day offers a standard three‑month return‑to‑base warranty on reconditioned, service exchange, new, and repaired products, counted from the date of delivery. Within the first fourteen days, if a product fails, they will replace it with an equivalent part or fully refund the purchase, including carriage, if no equivalent is available.

Industrial Automation Co. markets a twenty‑four‑month warranty on most refurbished components and notes that this is roughly double what they see as the typical industry standard for refurb. Similarly, Qualitrol backs its remanufactured PLCs with a two‑year warranty, positioning that term as a key differentiator and signaling confidence in the remanufacturing process.

Outside industrial automation, broader electronics data line up with this spread. CellularProfessor’s guide to refurbished device warranties describes refurbished warranties clustering between ninety days and one year, while Qviro notes that industrial automation warranties often center around twelve months, with paid extensions available.

A typical pattern for refurbished PLCs and related automation hardware therefore looks like this.

| Example source or pattern | Product type described | Warranty duration described |

|---|---|---|

| PLC2Day | Reconditioned, service exchange, repaired | Three months from delivery, with first fourteen days DOA replacement or refund window |

| PLC Exchange | Factory sealed and new/open box industrial parts | One year from delivery confirmation or deemed delivery date |

| Industrial Automation Co. | Refurbished PLCs, HMIs, VFDs | Twenty‑four months, described as about double typical refurb standard |

| Qualitrol | Remanufactured PLC parts | Two‑year warranty on PLCs |

| General refurbished electronics (CellularProfessor) | Consumer devices | Roughly ninety days to one year |

Take two things from this. First, warranty term is not a commodity; it is a design decision by each supplier. Second, long terms are not unheard of in refurb; multi‑year coverage exists today for PLCs when the refurbisher is confident in their process.

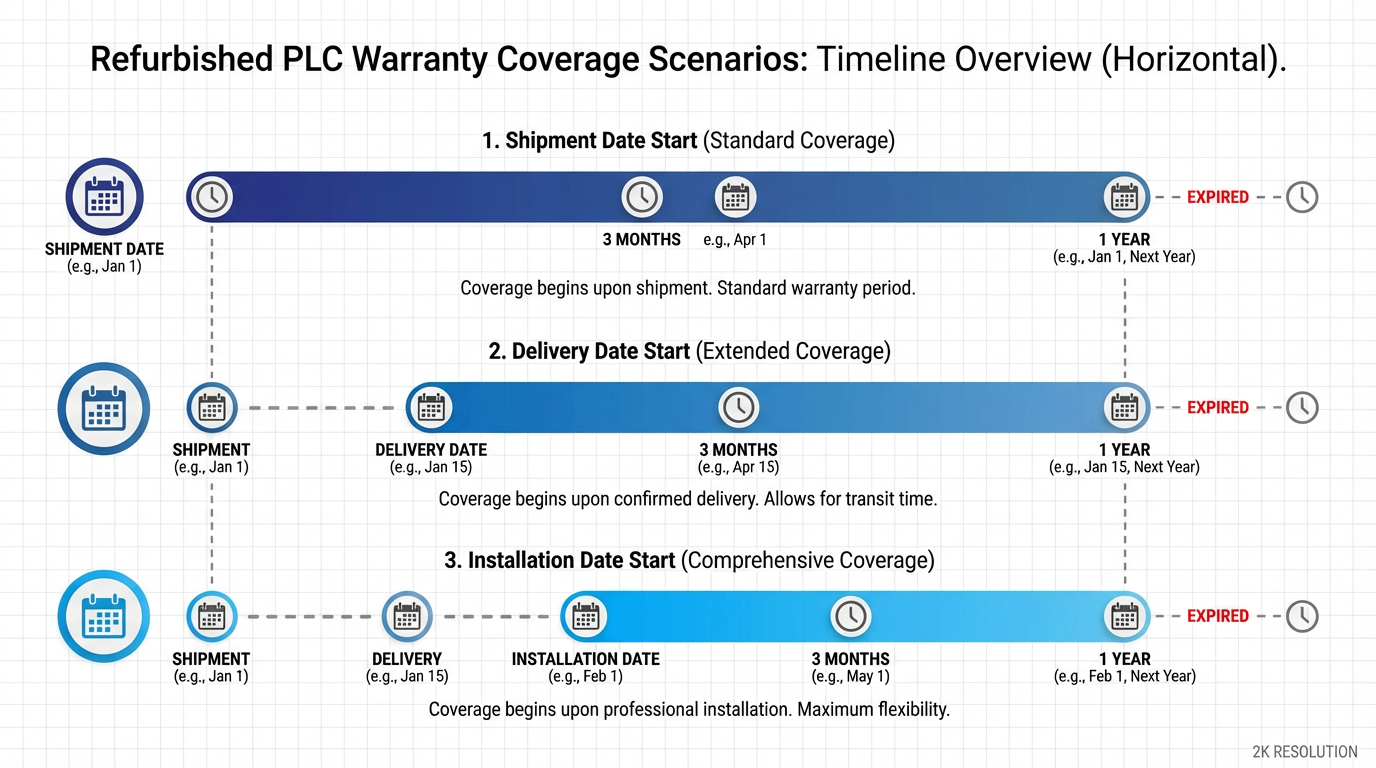

The start date matters just as much as the duration.

As PLC Exchange and PLC2Day show, some suppliers start the clock at delivery confirmation, others at shipment, others at installation. Qviro highlights start date as one of the five key clauses to review for any industrial automation warranty precisely because a few weeks’ difference can decide whether a borderline failure is covered.

What Is Usually Covered, And What Is Not

Most refurbished PLC warranties follow the same basic pattern as AutomationDirect’s limited warranty and similar industrial terms. Products are warranted to be free from defects in material and workmanship for a defined period. The customer’s exclusive remedy is repair, replacement, or refund of the purchase price, at the supplier’s discretion.

Coverage generally includes manufacturing defects and failures that appear under normal, specified use. PLC Exchange’s policy, for example, specifies that the warranty covers defects they classify as manufacturer defects, with the product evaluated after return. PLC2Day similarly guarantees that supplied and repaired products will be in working condition unless otherwise stated, and that their liability is limited to repair, replacement, or refund.

Exclusions are where things get serious. Across PLC Parts Solution, PLC2Day, PLC Exchange, PLC Ltd, AutomationDirect, and broader industrial and IT refurb sources like Zortex and Qviro, the same themes are repeated.

Improper installation or misuse is excluded. PLC Parts Solution notes that failure to follow manufacturer installation instructions and specifications voids coverage. They explicitly exclude damage from neglect, accidents, or unauthorized modifications. PLC Ltd excludes issues resulting from failure to follow manuals, unsuitable environments, and non‑compliance with safety standards. Zortex points out that refurbished IT warranties routinely exclude damage caused by incorrect use, incompatible materials, and poor installation.

Environmental and physical abuse are also excluded. PLC Parts Solution lists transport damage such as scratches, dents, or impacts; moisture or corrosive exposure; poor ventilation and overheating; and excessive mechanical vibration as grounds for denial. PLC Ltd excludes unsuitable or corrosive environments, liquid ingress, and physical damage from transport or storage, as well as force‑majeure events like fire and flooding.

Electrical abuse is another common exclusion. PLC Parts Solution states that unstable or incorrect power supply, operation beyond rated voltage, current, or speed, inadequate grounding, and malfunctions caused by electrical interference are outside warranty scope. PLC Ltd similarly excludes damage from lightning and other electrical disturbances.

Unauthorized repair or tampering usually voids the warranty outright. PLC Parts Solution specifies that tampering and unauthorized removal or replacement of internal components or boards void coverage. PLC Ltd notes that missing or altered serial markings, or the use of non‑genuine or non‑compliant parts, are grounds for denial. AutomationDirect’s general guidance also excludes failures due to unauthorized modifications.

Virtually every policy disclaims consequential damages. PLC Exchange’s policy states that warranty coverage does not extend to damage to personnel or other equipment, loss of profit, loss of time, or other indirect damages due to defective products. PLC2Day, PLC Ltd, and AutomationDirect all cap liability at the purchase price of the product and exclude indirect, incidental, or consequential losses. In other words, your lost production, emergency labor, and temporary power solutions are almost never covered.

When you read a warranty, therefore, focus less on the marketing statement at the top and more on what the supplier will not do if a refurbished PLC fails in the field.

Common Warranty Structures For Refurbished PLCs

Although language differs, refurbished PLC warranties tend to fall into recognizable structures.

One structure is a short dead‑on‑arrival window layered on top of a longer limited warranty. PLC2Day’s policy is a good example. For the first fourteen days after delivery, any failed product is replaced with an equivalent part, or fully refunded, including carriage, if no equivalent exists. After that window, the normal three‑month return‑to‑base warranty applies, where PLC2Day will attempt to repair the existing part or replace it, and only if that is impossible do they refund the original purchase price.

PLC Exchange defines two main outcomes for a valid warranty claim: replacement or return. Under “warranty replacement,” PLC Exchange replaces the product with a similar make or model of equal or lesser value, agreed upon with the customer. If no such product is available or the customer does not approve the replacement, they convert the case to a refund. Under “warranty return,” the original purchase price is refunded, typically excluding shipping. Both outcomes require that the item be returned for evaluation first.

Most policies are explicitly return‑to‑base. Customers must initiate a claim, obtain authorization, and send the product back to the supplier’s facility for evaluation. PLC Exchange, for example, requires customers to fill out a warranty request form, ship the item to their return address in Charlotte, and then wait five to ten business days after delivery for evaluation. PLC2Day and PLC Parts Solution similarly use return‑to‑base models, and PLC Ltd requires a Return Material Authorization and specific ship‑to instructions before accepting returned PLCs.

Some suppliers also have a defined inspection fee for no‑fault findings. PLC Ltd states that if a returned unit is found not to have a defect qualifying for replacement under the warranty, they will charge a flat inspection fee plus shipping and packaging costs. PLC2Day likewise reserves the right to charge testing fees and penalties for units found not faulty or damaged after delivery.

From a project perspective, this translates into three practical questions.

How quickly can you get a replacement or repair under this warranty structure? Who pays for shipping in each direction? And what happens if the supplier concludes the PLC is “no fault found” or damaged by conditions they consider outside spec?

The Warranty Clauses That Matter Most

Qviro’s industrial automation warranty guide calls out five clauses that engineers should always review. Those same five show up repeatedly in refurbished PLC warranties and are worth treating as a checklist.

When the Warranty Starts

Start date can be shipment date, delivery confirmation, or sometimes installation date. PLC Exchange explicitly starts the clock at carrier delivery confirmation or three business days after order if there is no confirmation. PLC2Day starts at delivery. Qviro highlights that many buyers mistakenly assume coverage starts at payment, which is not always the case.

In practice, this matters for spares on the shelf. If you buy a refurbished PLC as a spare and it sits untouched for six months before installation, a twelve‑month warranty starting at delivery gives you six months of in‑service coverage; a three‑month warranty might expire before you ever power it up. For high‑value spares that may sit for a while, it is worth negotiating either a longer term or an installation‑based start date.

Conditions That Void Coverage

Conditions that void the warranty are usually scattered throughout the exclusions. PLC Parts Solution lists improper installation, unauthorized modifications, electrical abuse, environmental extremes, and unauthorized repairs as all grounds for voiding coverage. PLC Ltd adds improper use, vandalism, unsuitable environments, missing serial numbers, and non‑genuine parts.

For teams that do in‑house board‑level repairs or frequently repurpose enclosures and fans, these conditions can be more than theoretical.

If you routinely swap fans or rework boards on site, you should assume that most refurbishers will consider that tampering and may deny later claims. Make sure your technicians understand that warranty and in‑house repair are often mutually exclusive choices.

What Is Covered In Practice

Coverage is more than just “parts and labor.” Qviro suggests checking whether the warranty includes shipping, on‑site support, remote diagnostics, and software updates. PLC suppliers echo this implicitly. PLC Exchange requires that warranty claims start with a return to their facility; PLC2Day limits liability to repair, replacement, or refund; PLC Ltd states that costs of removing, installing, or troubleshooting the customer’s electrical systems are not covered.

In many refurb scenarios, coverage is strictly for the module itself, at the refurbisher’s facility. Field engineering time, travel, panel work, and software engineering remain on your budget. That is acceptable if you plan for it; it becomes a nasty surprise only when teams have assumed “full coverage” based on a headline.

Duration And Extensions

Duration is where suppliers deliberately differentiate themselves. PLC2Day offers three months; PLC Exchange offers one year; Industrial Automation Co. and Qualitrol offer two years on refurbished PLCs; more general refurbished device guides such as CellularProfessor note ninety‑day warranties at the low end and one‑year terms as common.

Extended warranties are possible in some cases. Qviro describes extended warranties of one to three years for industrial automation equipment, sometimes taking total coverage up to around five years on high‑value assets. Zortex describes extended support and third‑party maintenance as tools to cover refurbished IT gear after initial coverage expires.

For a refurbished PLC running a critical line where downtime costs thousands of dollars per hour, paying for an extended warranty or choosing a supplier that offers a longer baseline term can be a rational insurance decision. For a training rig or low‑throughput test stand, a three‑month warranty might be sufficient.

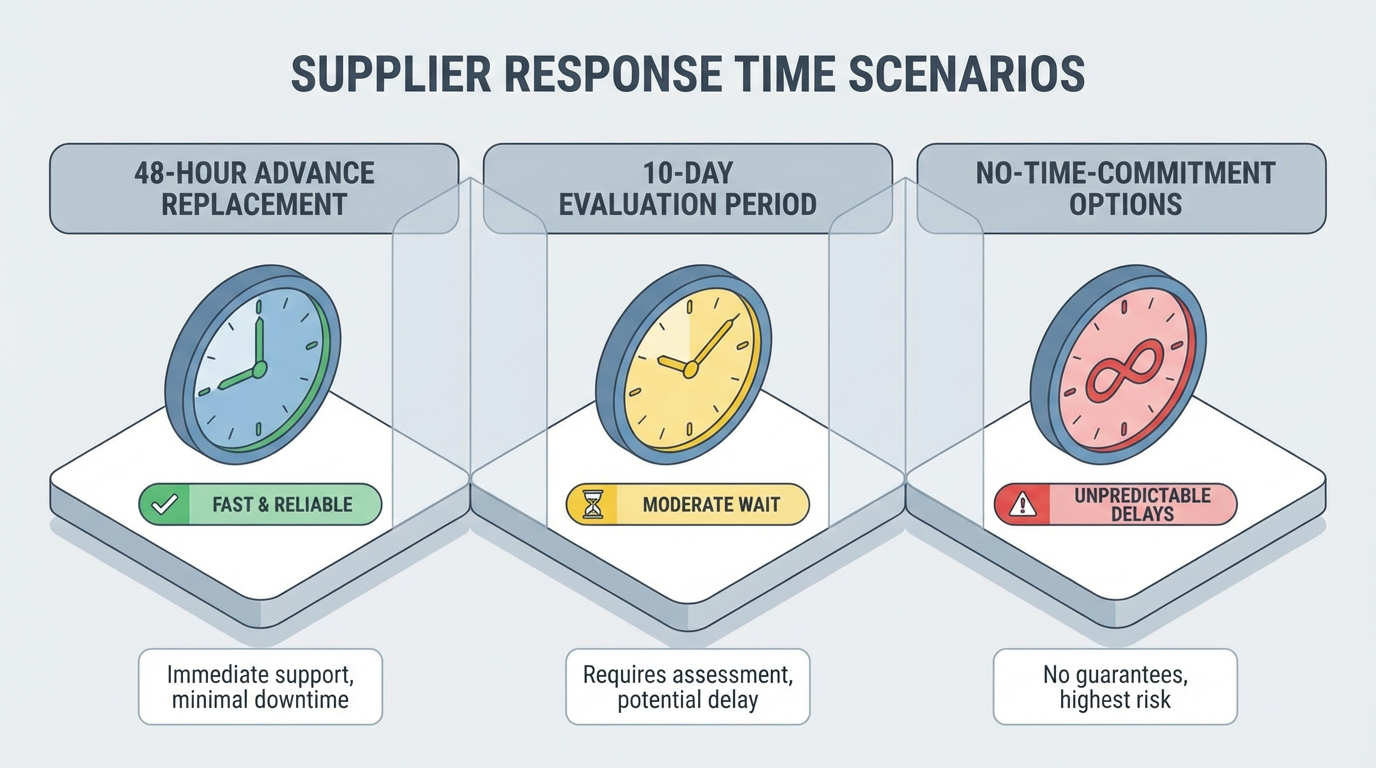

Expected Support Response Times

Warranty language often says little about response time, but Qviro emphasizes that it is just as important as coverage scope. If your supplier has ten business days to evaluate a returned PLC, and you have only one such PLC in the plant, your risk profile looks very different than if they offer advance replacement within forty‑eight hours.

Some suppliers implicitly show their stance. PLC Ltd notes that once an RMA is issued, they generally ship an equivalent replacement PLC within forty‑eight to seventy‑two hours. Zortex describes cases where OEM‑backed refurbished IT equipment benefited from four‑hour on‑site response for critical failures. On the other hand, many refurbishers explicitly state that shipping is ground, and that expedited freight is at the customer’s expense.

If uptime is critical, insist on knowing expected response times in writing.

That includes how quickly they will issue an RMA, how long evaluation will take, and whether advance replacement is available when you cannot wait for evaluation.

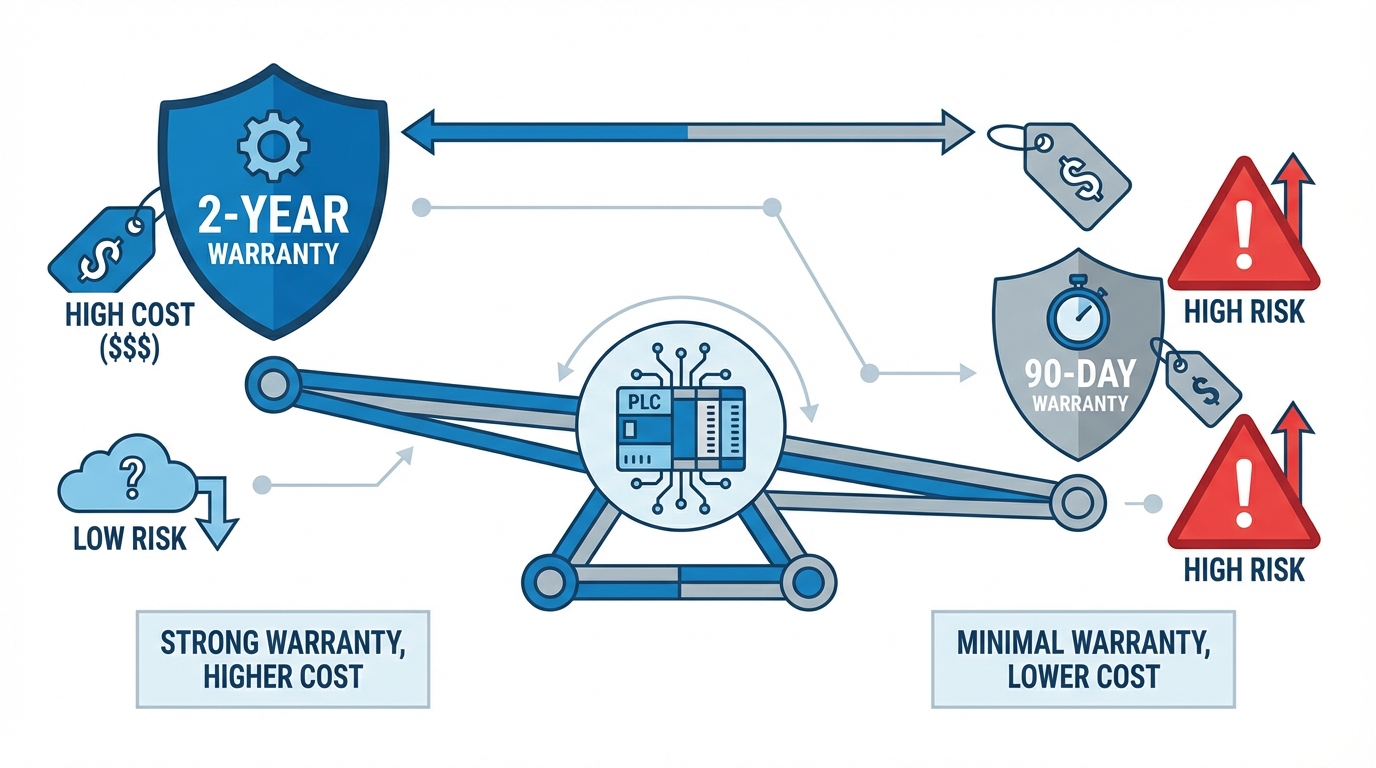

Pros And Cons Of Strong Refurbished PLC Warranties

A strong warranty does not magically make a bad refurb process safe, but it does change your risk posture.

From the positive side, clear, multi‑month or multi‑year warranties reduce financial exposure to early‑life failures. Industrial Automation Co. and Qualitrol both use two‑year terms on remanufactured PLCs as proof of confidence, and that confidence has value to you; it means the refurbisher expects the failure rate in that window to be manageable. Longer warranties also make it easier to justify refurbished hardware to financial stakeholders who are wary of non‑OEM parts.

A strong warranty can also support lifecycle strategies. Aeliya Marine Tech, for example, recommends six‑ to twelve‑month coverage as a sensible baseline and emphasizes advance replacement options. That kind of structure helps you use refurbished hardware not only as emergency replacements but also as planned spares, knowing that if a failure appears during commissioning or early operation, there is a defined path to relief.

The limitations are real, however. Even robust warranties usually exclude your biggest costs: downtime, production losses, and engineering labor. PLC2Day, PLC Exchange, PLC Ltd, and AutomationDirect all cap liability at the purchase price of the product and exclude consequential damages. Return‑to‑base structures mean you may still need to purchase additional spares or pay for expedited replacements in a real outage. And some strong‑sounding warranties come with dense exclusions and narrow interpretations of “manufacturer defect,” which can lead to disputes.

The tradeoff is often easiest to see in a simple comparison.

| Aspect | Strong refurb warranty (for example, two‑year term) | Minimal refurb warranty (for example, ninety days or “as‑is”) |

|---|---|---|

| Upfront price | Often slightly higher | Often lower |

| Early‑life defect risk | Largely shifted to supplier | Fully on buyer |

| Coverage of downtime costs | Typically none in both cases | None |

| Required spares strategy | Can sometimes run with fewer spares if advance replacement exists | Must carry more local spares or accept longer outages |

| Supplier confidence signal | High; supplier willing to absorb two‑year defect risk | Low; supplier avoids long‑term obligations |

Your job is to decide where on that spectrum each application should sit.

Evaluating Suppliers And Terms In Practice

When I review a refurbished PLC quote with a plant team, we focus less on which logo is on the module and more on which supplier we trust to stand behind it. The research backs that instinct.

Aeliya Marine Tech advises prioritizing specialist industrial automation refurbishers over generic resellers, looking for documented refurbishment procedures, unit‑specific test certificates, and clear DOA and return terms. Industrial Automation Co. emphasizes rigorous functional testing under real operating conditions as a prerequisite for any warranty. They recommend that buyers examine test reports that cover power integrity, I/O verification, communications, and environmental stress.

Traceability matters. Serial‑numbered test reports and inspection logs, as highlighted by Industrial Automation Co. and Aeliya Marine Tech, give you something concrete to tie a failure back to. They also make internal auditors more comfortable with refurbished hardware, because you can show that each PLC passed a controlled process.

Zortex and CellularProfessor both stress due diligence on the seller’s reputation and clarity of written warranty terms in the broader IT and electronics markets. They recommend checking customer reviews, asking for the formal warranty document, and understanding the claim process end‑to‑end before purchase. The same logic applies to PLC suppliers. If a refurbisher cannot provide their warranty policy in writing, or if they rely on vague phrases like “standard coverage” without details, that is a warning sign.

Finally, pay attention to how the supplier handles non‑covered cases. PLC Ltd’s inspection‑fee policy, and PLC2Day’s right to levy testing fees for non‑faulty returns, are not inherently unreasonable; suppliers cannot absorb unlimited diagnostic work. But you should know these terms up front and factor them into your risk calculations, especially if your team is likely to send in borderline cases.

Red Flags In Refurbished PLC Warranty Offers

Certain patterns should immediately prompt a deeper review or a different supplier.

The most obvious red flag is an “as‑is” sale or a refurbished PLC with no written warranty at all. Both Zortex and CellularProfessor caution that grey‑market or unregulated sellers often offer such deals, and that they are high‑risk in any production environment, because every failure translates directly into full replacement cost and downtime.

Another red flag is a warranty that sounds generous but is undermined by vague or sweeping exclusions. If “manufacturer defect” is never defined, or if exclusions are so broad that almost any real‑world failure could be blamed on installation, environment, or misuse, treat the warranty as weak until proven otherwise.

Vague or missing claim procedures are a third warning. PLC Exchange, PLC2Day, PLC Parts Solution, and PLC Ltd all provide explicit instructions for initiating a claim, returning hardware, and what happens next. In contrast, if a supplier cannot say how to file a claim, where to send a failed PLC, or how long evaluation will take, you should assume friction and delay until proven otherwise.

Finally, pay attention to sourcing transparency. Industrial Automation Co. notes that reputable refurbishers obtain parts from verified channels and maintain traceability. If a seller cannot say where their PLCs come from or how they were tested, no warranty language can fully compensate for that unknown.

Frequently Asked Questions

Can Refurbished PLCs Have Warranties As Long As New Ones?

In some cases, yes. Industrial Automation Co. and Qualitrol both offer two‑year warranties on refurbished or remanufactured PLCs, which is comparable to, or even longer than, many new equipment warranties in automation, where Qviro notes twelve‑month terms as common. More broadly, Qviro points out that even refurbished industrial robots from major OEMs can carry one‑year warranties similar to new units. The key is supplier capability and confidence, not the fact that the PLC is refurbished.

Does Using Refurbished PLCs Void My OEM System Warranty?

Industrial Automation Co. explicitly addresses the myth that refurbished parts automatically void system warranties. They note that refurbished components are often used outside OEM service agreements, particularly after official support ends, and that quality can be verified through documentation, test reports, and the refurbisher’s own warranty. Whether your specific OEM warranty or service contract allows third‑party hardware is a contractual question, so you should review those documents with your legal or procurement team. In practice, many plants use refurbished PLCs on legacy systems no longer covered by OEM agreements at all.

Is An Extended Warranty Worth It On Refurbished PLC Hardware?

Extended warranties and support contracts are essentially financial tools. Qviro and Zortex describe extended coverage as most valuable for high‑value, high‑usage, or hard‑to‑access equipment, where a major failure after the basic warranty could trigger large repair bills and downtime. For a refurbished PLC running a critical process line or an isolated remote station, paying for extra years of coverage can make sense, especially if it includes meaningful response times and advance replacement. For low‑risk applications, such as training benches or non‑critical test rigs, the cost of extension may not be justified. Weigh the extra warranty cost against realistic downtime and repair scenarios for that specific asset.

Closing Thoughts

Refurbished PLCs are no longer a fringe tactic; they are a mainstream way to keep legacy systems running, control capital spend, and avoid long lead times. The warranty is where your supplier puts their confidence in writing. If you treat that document as a core engineering input—reading the start dates, exclusions, claim process, and response commitments with the same rigor you apply to I/O counts and firmware versions—you can use refurbished hardware as a reliable part of your automation strategy, not a gamble.

References

- https://plcexchange.net/warranty-information/?srsltid=AfmBOop--tUqzsi2D2Kqf0mY6pfw8PqBeZeWM719vZFLUBdY85ALfzyA

- https://knowledge.apogeedigital.com/what-is-the-warranty-period-on-refurbished-units-bought-from-authorized-dealers

- https://www.ohtlstringingequipment.com/refurbished-tensioner-checklist-n.html

- https://www.plc2day.com/warranty

- https://www.plchardware.com/terms.aspx?srsltid=AfmBOoq9n7leCZY6tPQBU-gHL2ADKMU8b-rPueWiDJmKs0WP0R612GEu

- https://cellularprofessor.com/complete-guide-to-refurbished-device-warranties/

- https://blog.dipli.com/en/what-warranties-for-reconditioning-devices

- https://www.ebay.com/itm/195957964827

- https://plc-world.com/pages/warranty?srsltid=AfmBOoo78XqgW3MINGGvQnwsxQTjSGR_y9dHksj20O0Iyvy8YA440m-I

- https://www.plcltd.com/pages/plc-ltd-limited-warranty

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment