-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Siemens S7-300 Discontinued Modules: A Practical Guide to Legacy System Support

When you walk into a plant today and open a control cabinet, there is still a very good chance you will see a Siemens S7‑300 CPU staring back at you. These systems have quietly run production lines, water plants, and process skids for decades. Now the lifecycle notices are official, communications processors are on the phase‑out clock, and managers are asking the same question: how long can we safely ride this platform, and what is the smartest way forward?

This article takes the perspective I use when advising end users, OEMs, and fellow integrators on S7‑300 legacy support. It is grounded in Siemens lifecycle documentation, independent migration guides, and vendor case studies, and it reflects what actually works when you are responsible for uptime, not just architecture diagrams.

From Workhorse to Legacy: Where S7‑300 Stands Today

The S7‑300 family has been a mid‑range PLC backbone since the mid‑1990s, a successor to the SIMATIC S5 platform. It earned its reputation because it combined modular CPUs, a flexible I/O ecosystem, and good reliability at scale. According to industry analysis from Classic Automation, S7‑300 and the closely tied ET 200M distributed I/O have been deployed in millions of systems across discrete manufacturing, utilities, and energy, and they will remain relevant for maintenance even as production winds down.

However, Siemens has now formally moved S7‑300 into the late lifecycle phases. Public lifecycle information compiled by Patti Engineering shows that Siemens uses a structured five‑phase model for automation products, with P.M400 indicating a phase‑out announcement and P.M410 indicating product cancellation. For S7‑300 and ET 200M, P.M400 took effect on October 1, 2023, and P.M410 is set for October 1, 2025. Classic Automation notes that Siemens guarantees spare parts for S7‑300 and ET 200M at least until October 1, 2033.

In practice, that means new S7‑300 systems should not be used for greenfield projects, and even extensions of existing plants become increasingly difficult after cancellation. At the same time, you have a defined window in which spares, repairs, and structured migrations are still realistic.

Lifecycle and Discontinuation Milestones You Need to Know

Siemens’ lifecycle model, as summarized by Patti Engineering, is the backbone for any S7‑300 strategy discussion. In the active phase, products are marketed, updated, and recommended for new projects. Once a product reaches the phase‑out announcement, Siemens begins the ten‑year spare‑parts clock. During this phase, new units remain available, but no new functionality is added; the focus shifts to stability and security updates.

At product cancellation, new units are no longer sold for projects, and the platform becomes a spare‑parts source only. Firmware and security updates continue within the ten‑year spare obligation, but costs and lead times trend upward. When the spare‑parts obligation ends, users are effectively dependent on secondary markets and third‑party repair vendors. Eventually, at full end of lifecycle, even vendor repairs and formal support are withdrawn.

For S7‑300 and ET 200M, that translates into a clear timing profile. They are known to be in the phase‑out announcement phase now, move into product cancellation in late 2025, and retain Siemens spare‑parts backing through at least 2033. Beyond that date, you are planning purely on secondary sources and whatever stock you choose to hold.

The picture is similar for some S7‑300 communication modules. Siemens has published a dedicated phase‑out announcement for SIMATIC S7‑300 communications processors, listing CP 342‑5, CP 343‑5, CP 343‑1 Lean, CP 343‑1, CP 343‑1 Advanced, and the Compact Switch Module CSM 377. As of October 1, 2023, ordering as new remains possible with delivery guaranteed up to the type‑discontinuation point, but type discontinuation is planned for October 1, 2025. Siemens identifies S7‑1500 communication modules such as CM 1542‑5, CM 1542‑1, and CP 1543‑1 as successors in the modern platform.

The key takeaway for plant owners is simple. S7‑300 is a legacy technology with defined sunset dates, but it is not a dead platform yet. You have time, but that time needs to be used deliberately.

What Discontinued Modules Mean for Your Plant

Discontinuation itself does not stop a single motor. The immediate impact is on risk and cost.

First, spare‑part risk rises. Classic Automation points out that once product cancellation takes effect, plant expansions and new installations using S7‑300 or ET 200M will effectively no longer be feasible, because the supply of new units is constrained and reserved for one‑to‑one replacements. Prices rise, lead times stretch, and you start competing with every other plant that waited too long.

Second, unplanned downtime risk goes up. Industrial Automation Co. notes that many U.S. factories still run legacy hardware such as Siemens S7‑300 PLCs, and that once OEM support wanes and parts become scarce, a single failed module can halt an entire line and force expensive emergency responses. That is particularly true where a specific communication processor or special module becomes a single point of failure.

Third, modernization becomes harder the longer you wait. As Siemens and integrators invest in SIMATIC S7‑1500 and associated I/O systems, the toolchain, training, and expertise for S7‑300 shrink. Siemens documentation emphasizes that its products and solutions are only one component of a broader cybersecurity concept, and that protecting industrial systems requires up‑to‑date security measures. Running legacy PLCs indefinitely without a plan conflicts with that reality.

At the same time, full retrofits are not always realistic in the short term. Industrial Automation Co. stresses that a practical alternative to complete rewrites is the “control system refresh” approach: swapping obsolete components for modern equivalents that match form factor, connectors, and protocols, while reusing existing wiring, I/O, and logic. For many plants, the best path is a staged one, where you sustain, refresh, and migrate in phases.

Strategy 1: Sustain and Stabilize Existing S7‑300 Installations

If your S7‑300‑based machinery is stable and critical, keeping it running reliably for the next decade can be a valid strategy, as long as it is deliberate rather than passive.

Experienced practitioners participating in migration discussions on community platforms have made a simple, pragmatic recommendation: if an S7‑300 system is running reliably and there is no major redesign on the table, it is reasonable to continue maintaining it with Step 7 Classic and plan migration when you are already opening the panel for a larger hardware change. I share that view, provided you address three areas: hardware spares, programming constraints, and configuration hygiene.

On the hardware side, Classic Automation demonstrates one viable path. They stock, test, and repair S7‑300 CPUs, I/O modules, ET 200M interface units, and related communication or technology modules on dedicated Siemens test systems, backing repairs with a multi‑year warranty. Siemens itself promises spares until at least 2033. In practice, that suggests you should identify the modules that would stop production if they failed and secure at least one tested spare for each now, while supply is stable. Critical items often include CPUs, interface modules for ET 200M, key communication processors, and the I/O cards tied to safety or bottleneck processes.

On the programming side, you need to understand the limits of your existing CPU. A real‑world memory help question involving a CPU 315‑2DP illustrates why. In that case, an upgraded process required additional function blocks and data blocks, and the new program was larger than the original one. The CPU initially ran without a memory card, and the expanded program could not be downloaded because internal RAM was insufficient. Adding a 512 KB EPROM memory card and copying the existing program from RAM to ROM freed some RAM, but the user still faced a bottleneck when trying to load a significantly larger program.

The same thread highlighted a second issue: process image size. After adding a new ET 200 remote I/O station, new I/O channels were assigned at addresses around 340. The system only scanned I/O up to around address 295, so the new channels were not processed, even though they worked correctly when reassigned to lower addresses. The CPU configuration in use did not expose a setting to increase the process image area, unlike some newer models.

These examples show why a pure “run it until it fails” philosophy is dangerous. When you plan functional changes or expansions on S7‑300, you must verify CPU memory headroom and process image limits, and adjust design scope accordingly. Sometimes the right move is to trim legacy code, modularize data, or even introduce a small additional controller for new functionality rather than overloading an aging CPU.

Configuration hygiene is the third leg of the stool. Siemens product information regarding replacements of S7‑300 SM 321 and SM 322 modules in ET 200M stations controlled by S7‑400 CPUs highlights a subtle but critical behavior. In certain combinations of older and newer module variants behind IM 153 PROFIBUS DP interface modules, a field replacement could trigger I/O access errors, preventing the DP master from exchanging data with the replacement module. Siemens’ interim solution was clear. When replacing those modules, you must adapt the hardware configuration to explicitly use the new module types, then download the updated configuration, rather than relying on a like‑for‑like swap alone.

In day‑to‑day language, that means you cannot treat late‑lifecycle S7‑300 I/O as simple spare parts. You need documented hardware configurations, a robust procedure for updating and downloading them, and a plan for verifying compatibility of CPU and interface module revisions when you perform replacements.

Strategy 2: Direct-Fit Replacements Around S7‑300

Where risk, cost, or corporate standards make pure life‑extension unattractive, one compelling option is to modernize using direct‑fit replacement hardware that behaves like an S7‑300 system but is supplied by vendors focused on legacy support.

Industrial Automation Co. outlines a concept they call a control system refresh. Rather than ripping out control panels and rewriting ladder logic, they focus on sourcing compatible, drop‑in replacement drives and PLCs that mirror the legacy system’s voltage range, communication standards, and control behavior. In a real panel refresh example they describe, existing wiring paths and terminal blocks were reused while outdated drives and PLCs were replaced, resulting in a cleaner design, higher reliability, and no downtime for reprogramming.

For S7‑300‑centric applications, several vendors have built product lines around this idea.

VIPA positions its 300S+ control system as a direct, functionally equivalent alternative to Siemens S7‑300. According to VIPA’s own materials, 300S+ supports one‑to‑one exchange of S7‑300 I/O modules, with only small PLC changes required during migration. It uses the same programming language and very similar hardware setup, which means the engineering effort is far lower than a full platform change. Compared with S7‑300, they highlight faster processing performance and enhanced communication capabilities, including Ethernet, PROFINET, and common fieldbus protocols. The system is modular and scalable, and it is presented as a cost‑effective, future‑oriented upgrade path for users who want to preserve existing programs and know‑how.

Unimat Automation takes a similar but broader approach. Their coverage spans aging Siemens S7‑300 and S7‑200 PLCs as well as newer S7‑1200 and S7‑200 SMART systems. For the discontinued S7‑300 and S7‑200 series, Unimat offers dedicated replacement modules that match Siemens in size, electrical interfaces, DIN‑rail mounting, and bus interfaces. They describe their S7‑300‑compatible modules as one hundred percent hardware‑compatible and one hundred percent software‑compatible; existing STEP 7 projects are directly recognized, configured, programmed, and diagnosed without code changes, enabling genuine plug‑and‑play swaps. For S7‑1200 and S7‑200 SMART, their modules mirror Siemens form factors and can be engineered using TIA Portal or STEP 7‑Micro/WIN SMART, which allows near‑seamless project porting.

The benefits claimed by Unimat include zero‑risk replacements with no wiring or software modifications, preservation of existing control logic, HMI, and networks, and significantly lower procurement and maintenance costs than original Siemens modules. They recommend a disciplined implementation process: precisely identifying Siemens module models, consulting an authorized distributor for one‑to‑one replacements, running small‑scale validation tests for critical lines, then proceeding with installation and building a new spare‑parts inventory around the alternative modules.

From the integrator’s viewpoint, these compatible replacement strategies have clear pros and cons. On the positive side, they can dramatically reduce downtime, avoid wholesale program rewrites, and control costs at a time when official spare‑part prices are rising. On the caution side, you are stepping outside Siemens’ ecosystem. That brings questions of long‑term vendor viability, corporate qualification of non‑OEM parts, and alignment with your overall cybersecurity and support strategy. The right answer depends on how critical the process is, how strict your compliance requirements are, and how far you are from a major platform migration.

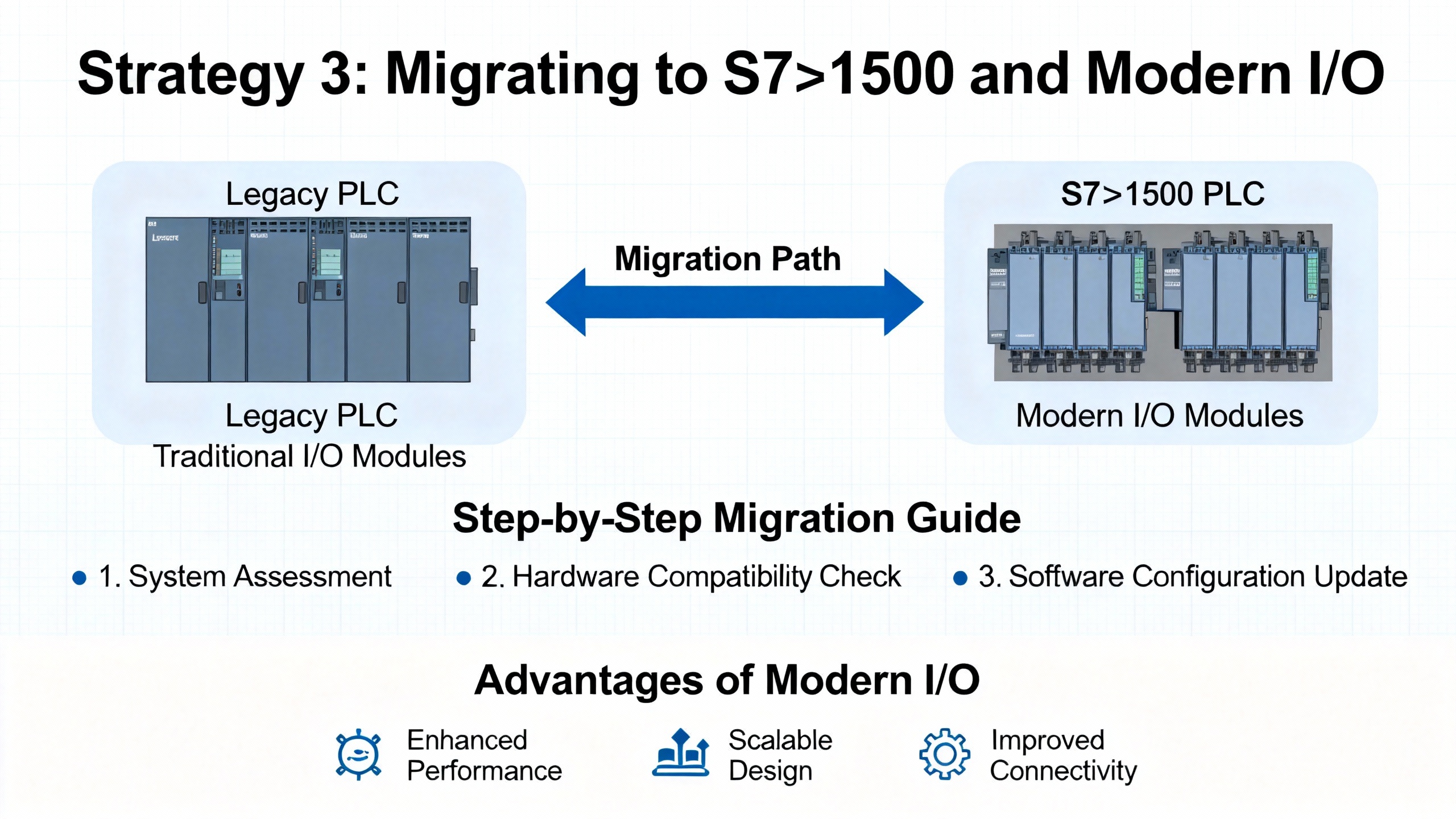

Strategy 3: Migrating to S7‑1500 and Modern I/O

Eventually, every S7‑300 owner has to address the migration question. Siemens is unambiguous about the successor landscape. For factory automation, SIMATIC S7‑1500 combined with ET 200MP or ET 200SP I/O is the recommended replacement. For high‑availability process automation, ET 200SP HA is the designated path.

A technical guide on migrating from S7‑300 and S7‑400 to S7‑1500 with TIA Portal highlights why this is more than a simple part swap. S7‑1500 CPUs offer substantially higher performance, more memory, integrated PROFINET and PROFIBUS interfaces, advanced web server diagnostics, and support for up to 192 simultaneous communication connections. They also bring richer protocol support, including OPC UA and time‑sensitive networking features, which ease integration with higher‑level MES and SCADA systems.

From a migration perspective, there are two pillars: hardware and software.

On the software side, Siemens provides tools to bring STEP 7 V5.x projects into TIA Portal. The TIA Portal environment includes a project migration capability that imports Simatic Manager projects, and, for S7‑300 and S7‑400 programs, a dedicated feature to adapt them to S7‑1200 and S7‑1500 targets. A community discussion on upgrading from Siemens S7 Classic to TIA emphasizes some important practical points. Before migrating, you should archive the Step 7 Classic project using Simatic Manager’s facilities and run a full consistency check and compile. Projects with inconsistencies do not import cleanly, and that step is often overlooked. Firmware and hardware compatibility is critical: older S7‑300 and S7‑400 firmware versions may not be fully supported, and users have sometimes had to upgrade to newer STEP 7 versions because TIA could not properly handle older hardware.

Once in TIA Portal, the project frequently needs debugging, especially for complex logic. Practitioners recommend thorough simulation and testing before deploying to production. Where automated migration is not satisfactory, a practical method is to keep both Step 7 Classic and TIA Portal open, analyze existing program blocks, and manually recreate or optimize the logic in TIA using newer S7‑1200 and S7‑1500 instructions.

Certain legacy functions do not map one‑to‑one. The S7‑1500 platform replaces many special function modules with technological objects and technology modules. For example, positioning and motion modules map into technological objects such as PositioningAxis, counting modules map to dedicated counting and position input modules, and PID technology modules are replaced with PID technological objects. The migration guidance notes that while tools exist, selectively rewriting complex sections often delivers cleaner architectures and better maintainability than pure automatic conversion.

On the hardware side, TIA Portal primarily supports hardware that was active as of late 2007. Some specialized S7‑300 variants and older panels fall outside its supported scope. When migration fails because of unsupported modules, the recommended approach is either to attempt hardware migration first and, if that still fails, to perform a software‑only migration and manually rebuild the hardware configuration with newer physical modules. That often implies replacing outdated S7‑300 CPUs and I/O cards with modern S7‑1500 and compatible I/O in the field while preserving as much of the original control logic as is technically and economically reasonable.

Effective migration planning, as laid out in the technical guide, follows a staged process beginning with a full plant assessment, followed by analysis, strategy development, detailed planning, execution, and post‑migration support, with explicit fallback plans where hot or warm migration is required. In my experience, successful projects also make use of Siemens’ TIA Selection Tool, which Siemens promotes as a quick, easy, smart way to configure SIMATIC‑based automation systems and to derive optimized hardware configurations for planned projects.

The modernization benefits are tangible. Reduced cycle times, improved diagnostics, better cybersecurity postures, and easier IT integration all accumulate over the life of a line. The tradeoff is upfront capital and engineering effort. That is why it often makes sense to align S7‑300 migration with other major events such as line rebuilds, capacity expansions, or regulatory‑driven upgrades.

Bridging S7‑300 with Other Platforms

In many brownfield plants, S7‑300 is not the only controller in the cabinet. You may be integrating it with S7‑400, third‑party PLCs, or new S7‑1500 cells. In these cases, bridging strategies can extend useful life and reduce migration pressure.

A practical example comes from a forum discussion on attempting to switch from an S7‑300 CPU to an S7‑400 CPU. Experienced engineers explained that S7‑300 and S7‑400 PLCs are physically different platforms. S7‑400 modules are roughly twice the height of S7‑300 equivalents and require a modular backplane, whereas S7‑300 uses support racks and bus connectors. As a result, you cannot simply drop an S7‑400 CPU into an S7‑300 rack.

However, they pointed out several ways to integrate S7‑300 I/O with an S7‑400‑based system. It is possible to configure an S7‑300 CPU as a PROFIBUS‑DP slave, effectively turning it into a smart remote I/O and data provider. Alternatively, you can replace the S7‑300 CPU with an IM153‑2 PROFIBUS slave interface module so that the S7‑300 I/O racks become distributed I/O stations on a PROFIBUS network. Data exchange between S7‑300 and S7‑400 can also be handled over Ethernet using CP343‑1 for S7‑300 and CP443‑1 for S7‑400, or via PROFINET connections, with the caveat that there are limitations on the amount of data that can be exchanged and that using S7‑300 communication processors as slaves can be challenging.

These bridging patterns apply equally when tying S7‑300 into a mixed environment that includes S7‑1500 or third‑party PLCs. When executed deliberately, they allow you to re‑use existing field wiring and I/O while moving higher‑level control, visualization, or sequencing to modern hardware.

Cybersecurity and Legacy S7‑300 Systems

Siemens is explicit in its discontinuation and phase‑out communications that technical products alone do not secure industrial environments. In their phase‑out notices for S7‑300 CPUs and communications processors, Siemens stresses the need for a holistic, state‑of‑the‑art IT security concept across infrastructures, systems, machines, and networks, and states that SIMATIC products and solutions are only one building block in that wider strategy.

They emphasize that software updates for active products include assessment and remediation of newly identified vulnerabilities or guidance on mitigation. However, there are inherent limits, particularly when third‑party components are involved or when maintenance has been discontinued and vulnerability information is no longer provided by suppliers.

Recommended measures from Siemens include staying alert for new security information, ensuring the latest firmware is installed, and using dedicated security components such as industrial security appliances to reinforce access control. For S7‑300 legacy systems that are not going to be replaced immediately, this implies a few pragmatic steps. Segment the control network, minimize unnecessary services and open ports, maintain firmware at supported levels while they remain available, and treat any direct internet connectivity from PLC networks as a serious red flag.

In many plants, the reality is that legacy PLCs sit at the edge of a growing industrial internet of things. Running those PLCs safely in that context requires network‑level controls and procedures that recognize their inherent limitations.

How to Decide: Sustain, Refresh, or Migrate

When I sit down with a plant that is heavily invested in S7‑300 and facing module discontinuations, the decision framework usually comes down to three intertwined questions.

First, how long must the existing machines run in their current form? If the answer is measured in a few years and the process is relatively stable, a sustain strategy backed by a structured spare‑parts plan, configuration cleanup, and minimal risk‑based upgrades may be sufficient. Siemens’ spare‑parts commitment through at least 2033 supports that path, especially when combined with reputable third‑party repair houses.

Second, what is your tolerance for unplanned downtime and last‑minute redesign? If the plant runs near capacity and every hour counts, relying solely on dwindling OEM spares is risky. In such cases, it can make sense to refresh control hardware around the S7‑300 platform using direct‑fit replacements from vendors such as VIPA or Unimat Automation or, at minimum, to build parallel test rigs for those alternatives so that you have a proven fallback if Siemens supply tightens faster than expected.

Third, where are you headed strategically with controls and data? If your long‑term roadmap includes tighter MES integration, advanced diagnostics, or digital transformation initiatives, at some point you will want the capabilities of S7‑1500, modern I/O families, and TIA Portal. Planning that migration early, aligning it with lifecycle milestones such as P.M410 and the ten‑year spare horizon, and using Siemens’ migration guides and selection tools can save you both money and operational headaches.

There is no one‑size‑fits‑all answer. What matters is that you turn discontinuation notices into a concrete lifecycle plan rather than a future problem.

FAQ: Common Questions About S7‑300 Discontinued Modules

Can I still buy new S7‑300 modules after October 1, 2025?

Siemens lifecycle information indicates that product cancellation around October 1, 2025, marks the end of selling S7‑300 and ET 200M as new units for projects. After that date, they become available only as spare parts for existing installations, and availability is constrained. Communications processors such as CP 342‑5 and CP 343‑1 are explicitly scheduled for type discontinuation on that same date. Siemens and independent suppliers like Classic Automation expect spare‑parts availability to continue for several years afterward, but you should not plan on ordering new S7‑300 hardware for expansions once cancellation has occurred.

Do I have to reprogram everything to migrate away from S7‑300?

Not necessarily. If your goal is to move off discontinued Siemens modules while preserving control logic and wiring, vendors such as VIPA and Unimat Automation offer S7‑300‑compatible PLCs and I/O that are designed for one‑to‑one replacement with minimal or no program changes. If you are migrating to Siemens S7‑1500, TIA Portal can import STEP 7 Classic projects and adapt them to the new platform, although you should expect to perform manual rework for special function blocks and complex logic. Industrial Automation Co.’s case studies show that in many situations you can treat upgrades as targeted refreshes rather than rewriting everything from scratch.

Is it safe to keep running S7‑300 systems until spare‑parts obligations end?

It can be, provided you actively manage the risks. Siemens has committed to spare‑parts availability for S7‑300 and ET 200M through at least October 1, 2033, and industrial service firms continue to test and repair these modules. Community practitioners note that S7‑300 systems that are running reliably today can often be maintained safely using Step 7 Classic until a major upgrade or hardware replacement is planned. However, you should not assume that spare‑parts and security updates will be seamless indefinitely. A sound strategy includes stocking critical spares, reviewing program size and I/O limits before making changes, aligning with Siemens’ cybersecurity recommendations, and placing a migration roadmap on the table well before vendor support winds down.

In the end, S7‑300 has earned its reputation as a durable workhorse. With a clear understanding of lifecycle milestones, realistic spare‑parts planning, and a pragmatic mix of sustain, refresh, and migrate strategies, you can respect that legacy while steering your plant toward a future you can rely on.

References

- https://www.academia.edu/4364142/Simatic_Configuring_Hardware_and_Communication_Connections_STEP_7

- https://do-server1.sfs.uwm.edu/exe/162S3780W3/slide/778S59W/siemens_sn__29500-standard.pdf

- https://www.plctalk.net/forums/threads/after-upgrade-from-s7-300-to-s7-1500-the-faster-cycle-times-have-an-affect-of-the-old-program.144857/

- https://www.classicautomation.com/blog/siemens-s7-300-and-et-200m-phase-out.html?srsltid=AfmBOopyoG3smQ9pRqaFUtOvayspEqfMlXSZGlh32gVbeXseRVwR2KYe

- https://www.linkedin.com/pulse/technical-guide-migrating-from-simatic-s7-300s7-400-mohamed-sayed-yeejc

- https://community.oxmaint.com/discussion-forum/how-to-upgrade-siemens-s7-classic-software-to-tia-v12-v18-import-legacy-programs-to-s7-1200-1500-platform

- https://industrialautomationco.com/blogs/news/smart-replacements-how-to-upgrade-legacy-systems-without-reprogramming-everything?srsltid=AfmBOop1jAS-ewgyeLNmKXbhX_xatyfKyttIbNZBAmPf9GmFIxLeCCyI

- https://www.pattiengineering.com/blog/siemens-lifecycle-and-upgrade-planning/

- https://www.unimatautomation.com/blogs/news-and-press/how-to-find-reliable-replacement-modules-for-aging-siemens-systems

- https://vipausa.com/categories/products/siemens-s7-300-plc-replacement-modules.html?srsltid=AfmBOoqwwHW_HBx2uhRW9US9in3SULsZXS40J5WpYINm7jEeyTqvTuhC

Keep your system in play!

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment