-

Manufacturers

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 3300 System

- 3500 System

- 3300 XL 8mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- 177230 Seismic Transmitter

- TK-3 Proximity System

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Siemens 6SL3 210-1KE23 G120 Drive Stock: Current Inventory and Purchase Options

This is my linkedin:

As a seasoned expert in the field of automation spare parts, Sandy has dedicated 15 years to Amikon, an industry-leading company, where she currently serves as Director. With profound product expertise and exceptional sales strategies, she has not only driven the company's continuous expansion in global markets but also established an extensive international client network.

Throughout Amikon's twenty-year journey, Sandy's sharp industry insights and outstanding leadership have made her a central force behind the company's global growth and sustained performance. Committed to delivering high-value solutions, she stands as a key figure bridging technology and markets while empowering industry progress.

When a SINAMICS G120 power module fails on a production line, the question that matters is simple: do you have a compatible replacement on the shelf, and can you drop it in without losing half a shift?

The Siemens 6SL3 210-1KE23 part number is one of those workhorse G120 modules that tends to sit in the middle of critical applications. From a systems integrator’s seat, the real value is not just in the drive itself, but in how you manage its stock, how you buy it, and how fast you can get a replacement online without re-engineering the machine.

This article walks through how the 6SL3 210-1KE23 fits into the SINAMICS G120 family, how to think about “current inventory” in a plant or fleet context, and what practical purchase options and stocking strategies actually work in the field. The perspective is pragmatic and grounded in commonly accepted inventory best practices and Siemens drive documentation, not in guesswork about live distributor stock or speculative lead times.

Where the 6SL3 210-1KE23 Fits in the SINAMICS G120 Family

Siemens positions SINAMICS as a broad drive family that spans simple pump and fan applications through to more complex motion and process duties in manufacturing, infrastructure, and utilities. Within that family, the SINAMICS G120 is the general-purpose, modular AC drive system.

Siemens marketing and portfolio overviews describe G120 as a modular platform built from separate power modules, control units, and operator interfaces. This modularity allows the same basic building blocks to scale from fractional‑horsepower conveyors up to more demanding production machinery. Typical G120 offerings cover power ratings from around 0.55 kW to 250 kW and support common industrial line voltages around 200 V, 400 V, and 690 V, which allows a single platform to fit many regional grids and machine sizes.

The 6SL3 210-1KE23 number identifies a specific hardware variant inside that modular G120 line. Siemens part numbers encode details such as product family, voltage class, power class, and design variant. The decoding tables sit in Siemens catalogs and data sheets, so the precise rating and options for 6SL3 210-1KE23 should always be confirmed against official Siemens documentation or SiePortal. What matters for inventory planning is that this is a defined, repeatable G120 module with a clear set of compatible control units, safety functions, and firmware families.

Modular Hardware and What It Means for Spares

Because G120 is modular, a typical installation will combine:

A power module similar to the 6SL3 210-1KE23, handling the main power electronics.

A control unit, which provides the intelligence: fieldbus interfaces, I/O, control modes, and safety functions.

An operator interface such as a basic or advanced operator panel, or a Smart Access Module.

Siemens and third‑party technical guides emphasize that this separation simplifies both engineering and maintenance. For spares, it also means the most effective strategy is rarely “one full drive per motor.” In practice, plants often standardize on a small set of power module sizes and control units. That lets you stock fewer unique part numbers while still covering most installed drives.

In this context, 6SL3 210-1KE23 should be treated as one of your “standard bricks.” When a line is designed, deciding to repeat that module wherever reasonable pays off later in spares simplicity: your stockroom carries depth in a handful of modules instead of dabbling in dozens.

Typical Applications Using G120 Hardware

According to Siemens application material and integrator guides, the SINAMICS G120 family shows up across a wide range of industries. A technical overview from Siemens and a detailed integrator guide from Naksh Technology describe G120 modules used in:

Manufacturing machinery such as presses, extruders, rolling mills, and general conveyors, where precise speed and torque control protect product quality and mechanical life.

Automotive production, including conveyors and process drives in paint shops and assembly lines, where flexible speed profiles and integrated safety are critical.

Water and wastewater pumping and aeration, where variable‑speed control enables significant energy savings compared with fixed‑speed operation and throttle control.

Food and beverage processes such as mixers, bottling lines, and conveyors, helped by the drive’s fine speed control and easy cleaning in appropriately designed systems.

Textile machinery, where accurate low‑speed torque and smooth acceleration protect delicate fibers and fabric quality.

Logistics and material handling, including warehouse conveyors and automated storage and retrieval systems, benefiting from communication options and scalability.

In all of these, the power module represented by a part number like 6SL3 210-1KE23 is the core hardware link between line power and the motor. That makes it a high‑impact item from an inventory perspective: if it fails and you cannot replace it quickly, your process stops.

Integrated Features That Influence Stock Decisions

Several characteristics of the G120 platform and its tooling affect how painful or painless a replacement will be. These are worth understanding up front, because they influence how aggressive you can be with lean inventory strategies.

Siemens literature and application notes highlight three themes across G120 deployments: integrated safety, energy efficiency, and ease of integration.

G120 drives commonly include safety functions such as Safe Torque Off (STO) and Safe Stop 1 (SS1), implemented directly in the drive. This can reduce external safety relays and wiring, but it also means any replacement module must match or exceed the required safety capabilities and be properly validated.

Energy‑saving features in the SINAMICS family, including G120, are designed to cut power consumption by adjusting motor speed to actual process needs and by offering dedicated energy‑saving modes. Siemens describes these functions as a way to make energy consumption transparent and to help users uncover conservation potential.

On the integration side, G120 drives usually support industrial networks such as PROFINET, PROFIBUS, and EtherNet/IP, along with serial protocols like USS or Modbus RTU. Siemens engineering tools like Startdrive in TIA Portal and the older STARTER software are used to commission and diagnose these drives, and Siemens documentation stresses that consistent engineering environments simplify lifecycle support.

All three factors are relevant to how you manage a specific module like 6SL3 210-1KE23. When you swap hardware, you are not just replacing a power brick; you are touching certified safety chains, energy optimization settings, and fieldbus configurations. That pushes you toward strategies that minimize variation in installed hardware and exploit tooling to make replacements as predictable as possible.

Inventory Best Practice Applied to a G120 Power Module

General inventory management references describe inventory as the policies, processes, and controls used to have the right products, in the right quantity, at the right place and time, while minimizing total cost. Total cost includes not just purchase price, but holding cost, handling cost, obsolescence, and the cost of stockouts.

For a high‑impact drive module, the stockout cost is obvious: lost production, missed shipments, and possible damage to upstream or downstream equipment. Best‑practice texts and Siemens’ own inventory management articles converge on a few principles that apply directly to a part like 6SL3 210-1KE23.

Treat Critical G120 Modules as A‑Class Items

Standard ABC analysis classifies inventory by cost and impact. High‑value or high‑usage items are treated as A‑class and receive tighter controls and more frequent review. Low‑value or slow‑moving items are C‑class and get simpler, lighter‑touch controls.

A G120 power module used on critical lines generally belongs in the A‑class. That does not mean you automatically stock a large number of units, but it does mean you manage it intentionally:

You track exactly where it is installed.

You define a target service level, for example a high probability of being able to cover a failure without waiting for external shipments.

You periodically review demand (actual failures and planned expansions) and lead times.

Balance Service Level and Cost with Explicit Policies

Best‑practice references recommend defining reorder points, economic order quantities, and safety stock levels based on lead time, demand variability, and desired service level. For a drive module, that means quantifying:

How many units you expect to need per year, including both failures and planned projects.

How variable that demand is; some years you might replace none, in others perhaps several.

How long a replenishment order typically takes, including supplier and internal approval delays.

Formal methods such as safety stock calculations and economic order quantity formulae exist, but in many plants the crucial step is simply to move from “gut feel” to a documented policy. Once you declare, for example, that a specific G120 module must never drop below a certain on‑hand quantity unless a replacement order is already in progress, the day‑to‑day decisions become straightforward.

A Siemens blog on inventory strategy underscores that pure just‑in‑time approaches, while powerful, can be fragile under supply disruptions. The article highlights how some manufacturers now blend just‑in‑time flows with targeted buffers for high‑risk items. For critical drives, that usually translates into keeping at least some on‑site or near‑site stock rather than relying entirely on rapid supplier shipments.

Use Data and Cycle Counting for Stock Accuracy

Textbook inventory guidance stresses data accuracy as a prerequisite for any policy to work. That includes disciplined transaction recording, cycle counting, and technology such as barcodes or RFID.

Applied to a G120 spare, this is not complicated. It means that when a 6SL3 210-1KE23 leaves the stockroom and lands in a cabinet, the system must reflect that movement. Inaccurate records create a dangerous illusion of coverage: the ERP system shows one spare on hand, but the shelf is empty when a failure occurs.

Cycle counting, where you regularly count small subsets of inventory instead of doing annual full counts, is well suited to high‑value electronics. You may count your critical drive modules monthly while leaving minor hardware for less frequent checks.

What “Current Inventory” Really Means for a G120 Module

When people ask about “current inventory” for a specific Siemens drive, the focus is often on a simple number: how many are in the building or available from a distributor. In practice, effective coverage comes from several layers of inventory and availability.

A useful way to think about the 6SL3 210-1KE23 is across inventory layers: on‑site, central corporate, and supplier‑side. Each plays a role in availability.

| Inventory layer | Typical location | What it covers | Advantages | Watch‑outs |

|---|---|---|---|---|

| On‑site spares for 6SL3 210-1KE23 | Maintenance or electrical storeroom at the plant | Immediate replacements for drives on critical equipment in that facility | Fastest possible response; no dependence on logistics or external systems when a failure occurs | Holding cost, risk of damage if stored poorly, potential obsolescence if the fleet migrates away from this module |

| Central corporate warehouse | Regional or national distribution center | Shared pool of G120 modules for multiple plants | Better aggregation of demand, potential for tighter control and more professional storage | Slower response than on‑site stock; requires robust internal logistics and clear priorities when multiple plants need the same module |

| Supplier or distributor stock | Authorized Siemens distributors or solution partners | New modules purchased as needed, possibly under frame agreements | Professional component storage, order consolidation, access to the broader Siemens portfolio | Lead‑time risk, competition for limited supplier stock during global disruptions, less visibility if you rely on ad‑hoc ordering |

| Vendor Managed Inventory or consignment | Stock physically at your site but owned or managed by the supplier | High‑criticality items like key G120 modules, replenished based on consumption data | Reduces your working capital while preserving high availability; supplier manages replenishment based on agreed rules | Requires strong trust and data sharing; works best when demand volumes justify the administrative overhead |

In many mature operations, “current inventory” is not just the count in a single storeroom but a coordinated picture across these layers. From a risk standpoint, you want to know not only how many 6SL3 210-1KE23 modules are on the shelf, but also where the next replenishment will come from and how exposed you are if a supplier suddenly extends lead times.

Inventory performance metrics such as fill rate, stockout frequency, and days of inventory on hand can also be applied specifically to critical drives. Even if you do not calculate them formally, it is worth tracking how many drive failures you have handled from stock versus how many caused extended downtime due to lack of a spare.

Purchase Options for Siemens 6SL3 210-1KE23

With inventory layers defined, the next question is where and how to buy 6SL3 210-1KE23 modules. The options below are framed generically, because real‑time distributor inventory and pricing are outside the scope of this article, but the structural choices are common across sites.

Buying Through Siemens and SiePortal

Siemens describes SiePortal as an integrated entry point that unifies its online support, engineering documentation, and Industry Mall purchasing environment. Technical articles on SINAMICS G120 tools point to SiePortal as the place to access function manuals, application notes, and related products.

For a module like 6SL3 210-1KE23, the advantages of going through Siemens’ own channels are predictable documentation and part compatibility. The catalog entry will clearly state the electrical rating, firmware family, and successor or replacement parts if the original variant is superseded. You can also cross‑check safety certifications and supported control units.

The trade‑off is that Siemens channels sometimes operate on more structured lead times than niche brokers. If you are planning a stocking strategy rather than reacting to a failure, that predictability is usually an asset.

Authorized Distributors and System Integrators

Many plants source SINAMICS G120 hardware through local or regional authorized distributors. In some cases, these distributors also provide engineering and commissioning services, effectively acting as system integrators.

Third‑party guides such as the Naksh Technology overview of SINAMICS G120 stress that working with experienced partners can help match the right power modules, control units, and options to your application. From a stocking perspective, a partner who knows your installed base can also suggest a rational consolidation of part numbers and an appropriate mix of spares.

When buying a specific module like 6SL3 210-1KE23, an authorized distributor can often advise on whether Siemens recommends a newer replacement variant, how long they expect to stock the original, and what cross‑compatibility looks like in practice. Those conversations feed directly into obsolescence planning.

Vendor Managed Inventory and Strategic Stocking Agreements

A Siemens inventory management article discusses Vendor Managed Inventory (VMI) as an arrangement where the supplier manages inventory levels at the customer location, using shared forecasts and consumption data. VMI is typically positioned for items with higher demand volatility, while classic just‑in‑time fits more predictable items.

For G120 modules, VMI or consignment agreements sometimes make sense where:

Multiple plants share a common Bill of Materials for drives.

Consumption is lumpy but significant across the fleet.

Capital budgets make it unattractive to buy and hold many high‑value electronics.

In such setups, a supplier might maintain a small pool of 6SL3 210-1KE23 units physically at your site or nearby, replenished automatically based on usage.

The key success factors, as Siemens authors note for VMI in general, are trust, transparency, and performance. If demand or lead times are not visible to both sides, the arrangement can fail just as easily as internal stocking can.

Just‑in‑Time Versus Buffers for Critical Drives

Traditional just‑in‑time thinking leans on short, reliable lead times and tight coordination with suppliers. A Siemens article on JIT and vendor managed inventory points out that this model works best when transport times are short and collaboration is strong.

The same article, reflecting on supply chain disruptions and events like the Fukushima earthquake, argues for a modified just‑in‑time approach: maintain flow for most items, but establish strategic stockpiles or extra capacity for high‑risk components. Toyota’s post‑disruption strategy, for example, required suppliers to hold several months of buffer stock for long‑lead semiconductors.

A G120 module powering a key process step is a textbook candidate for this kind of targeted buffer. In practice that means you may pursue efficient, relatively lean flows for most automation components, while still maintaining a defined on‑site or near‑site stock of 6SL3 210-1KE23 modules rather than relying purely on just‑in‑time deliveries.

Making Replacements Predictable: Tooling and Parameter Management

Once you own a spare module, the next bottleneck is how fast you can turn it into a fully functional drive on the machine. Siemens invests heavily in tools and accessories to make that process repeatable; using them well can justify a leaner physical stock because each replacement is less risky.

SINAMICS Startdrive: Commissioning and Safety Acceptance

Siemens describes SINAMICS Startdrive V20 as a commissioning and diagnostics tool integrated into TIA Portal for SINAMICS drives. According to Siemens product information, Startdrive V20 comes in Basic and Advanced editions in a single download package:

The Basic edition provides commissioning and diagnostic functions for supported SINAMICS devices.

The Advanced edition includes all Basic functionality and adds an integrated safety acceptance test for drive families including SINAMICS S120, S210, G115D, G120, and G220.

No additional installation is required to access Advanced features beyond the common package; enabling them is a matter of applying the appropriate license key.

For a G120 power module like 6SL3 210-1KE23 operating in a safety‑related application, using Startdrive Advanced allows you to formalize and document the safety acceptance test each time you replace or significantly modify a drive. That is good practice in its own right, and it also reduces the risk that a replacement spare introduces subtle safety misconfigurations.

G120 Smart Access Module: Wireless Access, Diagnostics, and Backup

A Siemens partner demonstration of the SINAMICS G120 Smart Access Module describes it as a Wi‑Fi accessory that mounts where the usual operator panel sits and provides a browser‑based interface to the drive. Once installed, the module quickly creates its own Wi‑Fi network; you connect with a phone, tablet, or laptop and point a browser at a fixed private IP address.

The web interface presents dedicated tiles for commissioning, parameter access, jog and hand control, monitoring, diagnostics, and backup/restore. Two capabilities of this module are particularly relevant to stocking and replacements:

You can back up the full parameter set from a configured drive into the Smart Access Module, export it, and store it on removable media.

You can restore that parameter set into a new or repaired drive, standardizing configurations across multiple units.

From a spares strategy standpoint, this means a spare 6SL3 210-1KE23 does not have to be pre‑loaded with every parameter. As long as you maintain reliable, version‑controlled backups of the parameter sets for each application, you can install a fresh module and restore the correct configuration quickly and consistently.

PLC and HMI Templates for Drive Configuration

A tutorial from SolisPLC on G120X and G120XA drives illustrates another pattern that applies conceptually to G120 modules in general. In that example:

An S7‑1200 PLC uses predefined function blocks to read and write drive parameters over PROFINET using a free telegram.

An HMI provides structured screens for monitoring, initial setup, and parameter backup and restore.

The workflow includes factory reset, batch parameter writing for motor data and line voltage, and explicit save, backup, and restore steps.

The details in that tutorial are specific to G120X/XA, but the underlying principle is universal: if you build a standardized commissioning recipe into your PLC and HMI, replacing a drive module becomes a guided process rather than an improvised job. That in turn reduces the perceived need to stock “pre‑configured” drives for each machine, and makes centralized stocking of generic 6SL3 210-1KE23 modules more viable.

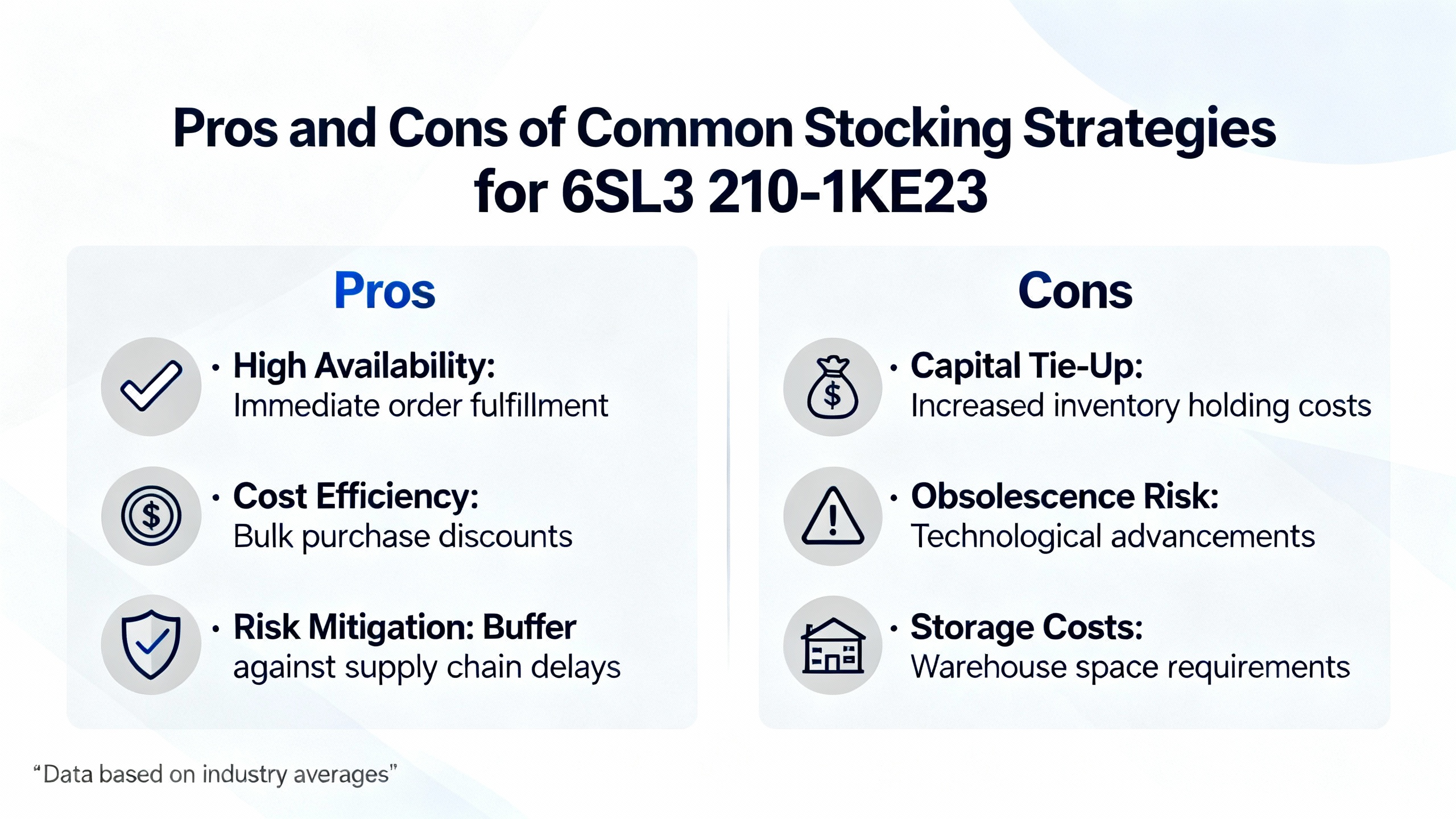

Pros and Cons of Common Stocking Strategies for 6SL3 210-1KE23

Different plants adopt different stocking philosophies. The table below summarizes, in qualitative terms, how common strategies play out for a critical G120 power module.

| Strategy | Description | Pros | Cons / Risks | When it fits |

|---|---|---|---|---|

| High on‑site stock | Maintain multiple 6SL3 210-1KE23 units physically in each plant | Maximizes self‑reliance and minimizes downtime due to part availability | High working capital and storage requirements; potential obsolescence if the installed base changes | Sites with severe downtime cost and limited logistics, or where corporate policy mandates local autonomy |

| Modified just‑in‑time with targeted buffer | Keep a small defined on‑site buffer, rely on fast replenishment for anything beyond | Balances cash use with reliability; follows Siemens recommendations for mixed JIT plus strategic buffers | Requires accurate demand and lead‑time data; vulnerable if supplier lead times suddenly stretch | Plants with reliable distributor relationships and decent logistics infrastructure |

| Vendor Managed Inventory or consignment | Supplier owns or manages a pool of modules on or near your site | Lowers capital footprint while preserving availability; leverages supplier expertise | Needs robust contracts and high trust; complex for low‑volume items | Multi‑plant organizations with strategic supplier partnerships and enough aggregate demand |

| Pure just‑in‑time (no buffer) | No dedicated stock; order on failure | Minimizes holding cost and avoids obsolescence | High risk of long downtime during supply disruptions; fragile under global shocks | Rarely appropriate for critical drives; might be acceptable for non‑critical or duplicated equipment |

The modified just‑in‑time model with explicit buffers is increasingly common, reflecting industry experience from major disruptions. Instead of treating every component the same, you classify items like the 6SL3 210-1KE23 as strategic and deliberately exempt them from the leanest stocking rules.

A Practical Stock Planning Workflow for This Drive

Putting the pieces together, a practical workflow for planning stock of a G120 module such as 6SL3 210-1KE23 looks something like this, expressed in terms of activities rather than equations.

Start by mapping where the module is installed and how critical each application is. A drive on a non‑redundant main process line deserves a different treatment than one on a rarely used auxiliary conveyor.

Classify the module as an A‑class item and estimate annual demand using historical failures and future project plans. Remember to include expected retrofits and expansions where the same module will be used.

Work with procurement and your Siemens partner to understand realistic lead times and volatility. This is where you incorporate lessons from the Siemens inventory management work on JIT versus just‑in‑case approaches.

Choose a stocking model that aligns with your risk appetite: on‑site spares only, shared central stock, VMI, or a blend. Document the expected role of each inventory layer in covering a failure.

Define clear reorder points and review cycles in your ERP or CMMS system. Do not leave reordering at the mercy of ad‑hoc emails; configure system triggers based on minimum on‑hand levels or forecast consumption.

Finally, pair your physical stocking strategy with a commissioning strategy based on Startdrive, Smart Access Module backups, or PLC/HMI recipes. The less uncertainty there is in the replacement process, the less pressure you feel to over‑stock “just in case.”

Short FAQ

Is it safe to rely on pure just‑in‑time supply for a G120 module like 6SL3 210-1KE23?

Industry discussions on inventory after major disruptions caution against pure just‑in‑time for strategic components. Siemens’ own commentary suggests a modified just‑in‑time approach, where flow is maintained but high‑risk parts get targeted buffers. For a drive module that can stop a line, it is prudent to hold at least some buffer stock rather than depend exclusively on rapid supplier deliveries.

How can I reduce commissioning time when swapping this module?

Siemens tools are designed to make replacements repeatable. Using SINAMICS Startdrive in TIA Portal for parameter management and safety acceptance testing, combined with the G120 Smart Access Module or PLC/HMI‑based parameter backup and restore, lets you treat a replacement as a controlled procedure instead of a fresh engineering task. Maintaining up‑to‑date parameter backups for each application is central to this approach.

Should I standardize on a small set of G120 part numbers across the plant?

Siemens documentation emphasizes the modular nature of G120 to enable standardization. Third‑party guides highlight the benefits of choosing a limited range of power module and control unit combinations. From an inventory and maintenance perspective, consolidating onto a small set of part numbers, including 6SL3 210-1KE23 where it fits, reduces the complexity of your stock and allows you to carry deeper, more effective coverage on each variant.

As a systems integrator, I have seen more downtime lost to missing or mismatched drive spares than to the drives themselves. Treat the Siemens 6SL3 210-1KE23 not just as a catalog number, but as a strategic asset in your inventory policy. If you couple disciplined stocking with the right commissioning tools and parameter management, each G120 module becomes a predictable, low‑drama replacement rather than a late‑night scramble.

References

- https://scholarworks.waldenu.edu/cgi/viewcontent.cgi?article=19338&context=dissertations

- https://admisiones.unicah.edu/book-search/CvP1Fh/0OK016/best-practice_in_inventory_management.pdf

- https://pressbooks.usnh.edu/businessopsanalytics/chapter/inventory-management/

- https://afs.gogcg.com/blog/siemens-sinamics-g120-smart-access-module-demo

- https://manuals.plus/m/b3daec52fe605455950caaa1861f3015a6d139552e91ea3b432810f2602655b7

- https://www.nakshtechnology.com/your-go-to-guide-for-sinamics-g120-drives/

- https://www.precision-elec.com/siemens-variable-frequency-drive-guide/?srsltid=AfmBOoqbOebj0uqKx-dFQrCoDQ5VJEQPuzE3nLyOFEl_or8g3iE3Y64c

- https://www.qualitymag.com/articles/98929-siemens-xcelerator-platform

- https://www.solisplc.com/tutorials/siemens-g120x-xa-drive-configuration-with-hmi-template

- https://publikacje.siemens-info.com/pdf/668/G120%20Safety%20Functions.pdf

Keep your system in play!

Related Products

Related articles Browse All

-

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu...

amikong NewsSchneider Electric HMIGTO5310: A Powerful Touchscreen Panel for Industrial Automation2025-08-11 16:24:25Overview of the Schneider Electric HMIGTO5310 The Schneider Electric HMIGTO5310 is a high-performance Magelis GTO touchscreen panel designed for industrial automation and infrastructure applications. With a 10.4" TFT LCD display and 640 x 480 VGA resolution, this HMI delivers crisp, clear visu... -

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ...

BlogImplementing Vision Systems for Industrial Robots: Enhancing Precision and Automation2025-08-12 11:26:54Industrial robots gain powerful new abilities through vision systems. These systems give robots the sense of sight, so they can understand and react to what is around them. So, robots can perform complex tasks with greater accuracy and flexibility. Automation in manufacturing reaches a new level of ... -

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

BlogOptimizing PM Schedules Data-Driven Approaches to Preventative Maintenance2025-08-21 18:08:33Moving away from fixed maintenance schedules is a significant operational shift. Companies now use data to guide their maintenance efforts. This change leads to greater efficiency and equipment reliability. The goal is to perform the right task at the right time, based on real information, not just ...

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shipping Method Return Policy Warranty Policy Payment Terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Amikong News Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

We use cookies and similar technologies on our website and process your personal data (e.g. IP address), for example, to personalize content and ads, to integrate media from third-party providers or to analyze traffic on our website. Data processing may also happen as a result of cookies being set. We share this data with third parties that we name in the privacy settings.

The data processing may take place with your consent or on the basis of a legitimate interest, which you can object to in the privacy settings. You have the right not to consent and to change or revoke your consent at a later time. This revocation takes effect immediately but does not affect data already processed. For more information on the use of your data, please visit our privacy policy.

Below you will find an overview of all services used by this website. You can view detailed information about each service and agree to them individually or exercise your right to object.

You are under 14 years old? Then you cannot consent to optional services. Ask your parents or legal guardians to agree to these services with you.

-

Google Tag Manager

-

Functional cookies

Leave Your Comment