-

Manufacturers

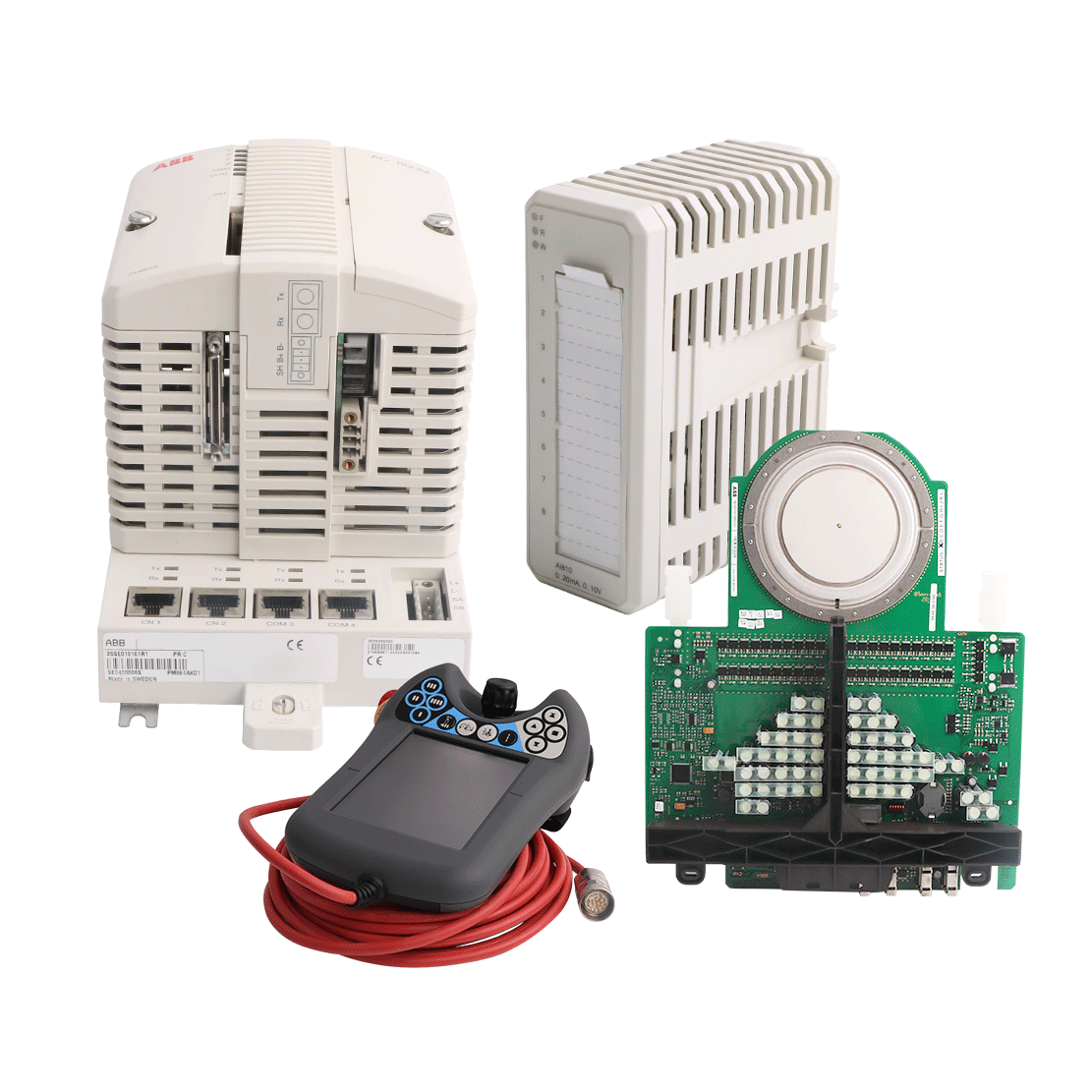

- ABB Advant OCS and Advant-800xA

- ABB Bailey

- ABB Drives

- ABB H&B Contronic

- ABB H&B Freelance 2000

- ABB Master

- ABB MOD 300, MOD 30ML & MODCELL

- ABB Procontic

- ABB Procontrol

- ABB Synpol D

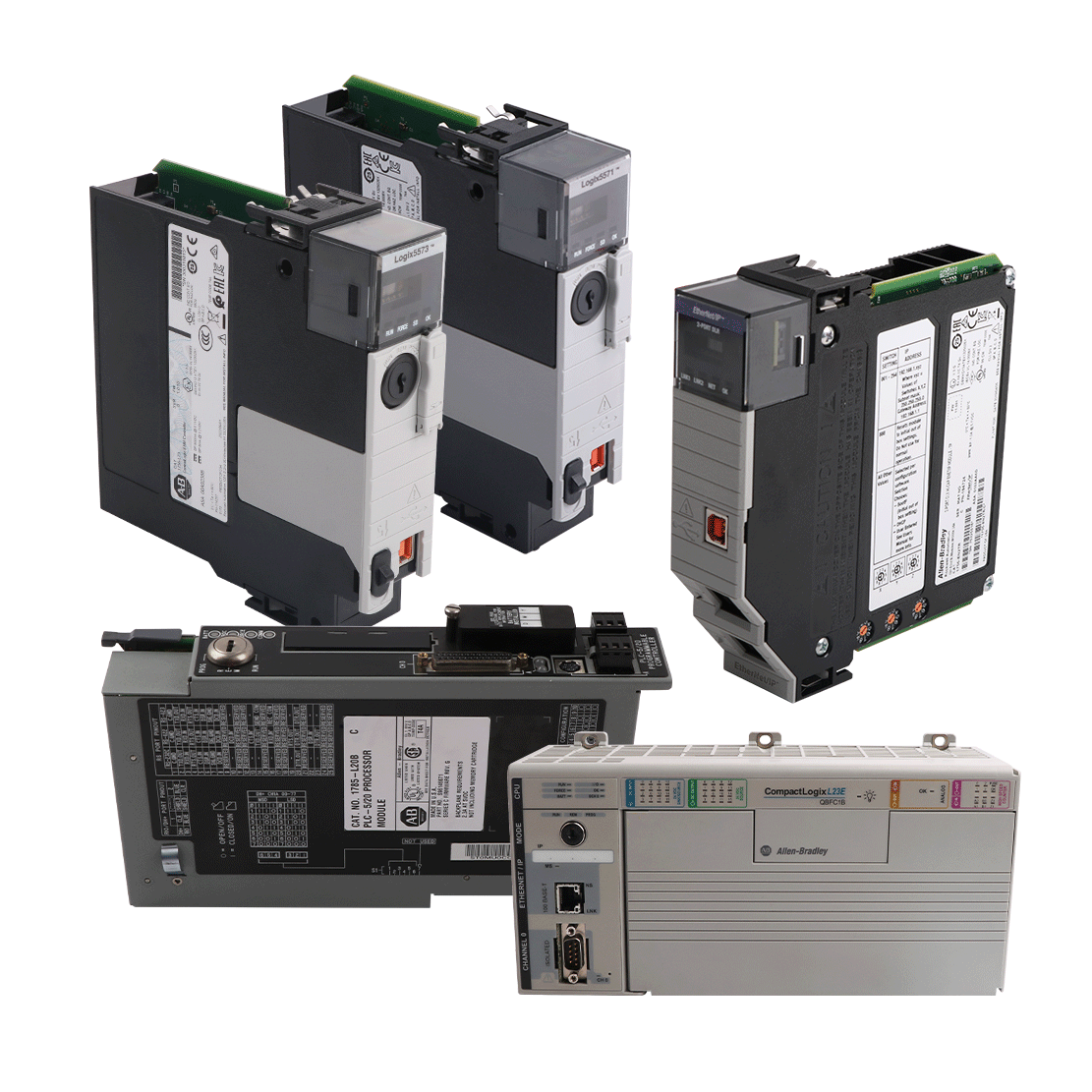

- Allen-Bradley SLC 500

- Allen-Bradley PLC-5

- Allen-Bradley ControlLogix

- Allen-Bradley CompactLogix

- Allen-Bradley MicroLogix

- Allen-Bradley PanelView

- Allen-Bradley Kinetix Servo Drive

- Allen-Bradley PowerFlex

- Allen-Bradley Smart Speed Controllers

- 21500 TDXnet Transient

- 3300 System

- 3500 System

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 177230 Seismic Transmitter

- TK-3 Proximity System

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- GE 90-70 Series PLC

- GE PACSystems RX7i

- GE PACSystems RX3i

- GE QuickPanel

- GE VersaMax

- GE Genius I/O

- GE Mark VIe

- GE Series One

- GE Multilin

- 800 Series I/O

- Modicon 984

- Modicon Premium

- Modicon Micro

- Modicon Quantum

- Telemecanique TSX Compact

- Altivar Process

- Categories

- Service

- News

- Contact us

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

-

-

Get Parts Quote

Bently Nevada

Comprehensive plantwide condition monitoring and protection systems.

We are Bently Nevada Supplier. We offer a plant-wide protection hardware, sensor, probes products that help you achieve the highest level of asset reliability possible.

All Manufacturers

-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for “”.

- Bently Nevada

-

ABBAccutracAcopianAC TechAction InstrumentsAdamAdaptecAdvanced Input DevicesAdvanced Micro ControlsAEGAISAlcatelAllen-BradleyAllied Telesis3MAlstomAMCIAntex ElectronicsApparatebau HundsbachArray ElectronicAseaASTECAutomation DirectAydin ControlsB&RBalluffBanner EngineeringBarco SedoBartecBECKBeierBeijer ElectronicsBently NevadaBerthelBiviatorBlack BoxBlockBofors ElectronikBoschBraunBürkertBURLECanaryCarroll TouchCEAG3COMConracControlonCooper BussmannCooper Crouse-HindsCopes VulcanCromptonCrouzetControl TechniquesCTI-Control Technology IncCustom Servo MotorsCutler-HammerDanfossDaniel WoodheadDEC - Digital Equipment CorpDelta Computer SystemsDelta ElectronicsDevolDGD Gardner DenverDIA ElectronicDIGIDigitalDigitronicsDuragDynaparEATONEBELTEberleEchelonE. Dold & Söhne - DOLDEES Elelkra ElektronikEILeka TechnikElecktro-AutomatikElectronics Development Corp – EDCEletec ElektronicElliot AutomationElographicsEmersone-motionEndress HauserEntrelec SchieleEPIC DataERMAERO ElectronicEtherComESDESS StörcontrollerETSI - Electronic Technology SystemsEurothermFanucFarnellFEASFestoFinder VaritecFischer PorterForney EngineeringFOTEKFuji ElectricGalil Motion ControlGeneral ElectricGildemeisterGordosGrapha ElectronicGrayhillGrenzebach ElectronicsHartingHawaHedin TexHEIDENHAINHelmholzHerren ElectronicsHex Valve – RichardsHIMAHirschmannHitachiHitexHK SystemsHoneywellHorner - FACTSHüller HilleibaIBHsoftecIBMidecIDSIFM ElectronicINATINIVENIntelInvensysIPF ElectronicJAQUETJetter AGKentKEPCOKettnerKieback & PeterKlockner MoellerKnielKöster SystemtechnikKoyoKrauss MaffeiKuhnkeLambdaLandis GyrLauerL&N - Leeds & NorthrupLenzeLeukhardt SystemsLG GoldSecLiebherrLittlefuseLumbergLutzeMagnecraftMannesmannMatric LtdMatsushitaMDB SystemsMean WellMeasurement SystemsMeasurexMEDARMicro Innovation AGMicron Control TransformersMitsubishiMolexMoogMSC TuttlingenMTL Insturments GroupMTSMurr ElektronikMyers Power ProductsNAISNandi PowertronicsNECNetstalNeumannNiobrara R&DNobel ElektronikOmega EngineeringOmronOpto 22Orbitran SystemsPANALARMPenril Datability NetworksPepperl + FuchsPesterPhilipsPhoenix ContactPilzPlasmaPlüth EnergietechnikPotter & BrumfieldRamsey EngineeringRed LionReis RoboticsReliance ElectricRexrothRinck ElectronicRIS - RochesterRMPRobust Data CommRonanRWTSAE ElektronikSAIASATT ControlSauterSchad SinTecSchaffnerShawmut - Gould/FerrazSchieleSchildknechtSchiller ElectricSchleicherSchleuniger AGSchlicht + KüchenmeisterSchlumbergerSchneider ElectricSchrack TechnikSCM PC-CardSelectronSensyconSEWSigma Information SystemsSixnetSOHARDSorcusSpectrum ControlsSprecher + SchuhSPS TechnologiesSquare DStahlStandard MicrosystemsSTI - Scientific Technologies, Inc.StrombergStruthers-DunnSUTRON ElectronicSYNATEC ElectronicSyslogicSysMikTaylorTecnint HTETelemecaniqueTillquestTimontaToshibaTransition NetworksTR ElectronicUhlmannUnicompUniOPUnited SciencesVAHLEVan DornVibro-MeterVIPAVisoluxWachendorff AdvantechWagoWalcherWeberWeidmullerWenglorWestronicsWielandWöhrleWolfWoodwardWürth ElektronikYokogawaZebra TechnologiesZiehl-AbeggZollnerXycomEprobachmannSaftronicsSiemensKEBOpti MateAristaSankiDaiei KogyoshaBrooks CTI-CryogenicsMKSMatrixMotortronicsMetso AuttomationProSoftNikki DensoK-TEKMotorola VMEForce Computers IncBerger LahrICS TriplexSharp PLCYASKAWASCA SchuckerGrossenbacherHachMeltalBremerMolex WoodheadAlfa LavalSiemens RobiconPerkinsProfaceSupconCarlo GavazziDEASSTHollysysSOLIDSTATE CONTROLSETEKOPTEKKUKAWHEDCOindramatMiscellaneous ManufacturersTEKTRONIXRorzeDEIFSIPOSTICS TRIPLEXSHINKAWAANYBUSHVAGERMAN POWERKONTRONENTEKTELSYSTEMKOLLMORGENLAZERPRECISION DIGITALLUBRIQUIPINCNOKIASIEI-GefranMSA AUER MUTKEBAANRITSUDALSALoad SharerSICKBradSCHENCKSTAIGER MOHILOENTERASYSUSB-LGTRSBIOQUELLSCHMERSALCORECOKEYENCEBIZERBABAUERBAUERCONTROLPACIFIC SCIENTIFICAPPLIED MATERIALSNMBNIWeishauptWeinviewCISCOPARKERLenovoKONECRANESTURBULHMSHOFFMANHUTTINGERTDK-LambdaRESOLVERKnickATLASGAMXTDKCAMERONNSKTamagawaGIDDINGS & LEWISBENDERSABOWOODHEADFRICK YORKSHENLERBALDORLam ResearchNTN BEARINGETAWEST INSTRUMENTSTDK-LambdaSMCFireyeDAHUATESCHACROSSERFLUKESanyo DenkiBruel & KjaerEPSONHIOKIMettler ToledoRAYTEKEPCOSDFISEMIKRONHuaweiINDUSTRONICASI-HVEBARTEC POLARISAMATGD BolognaPrecise AutomationRADISYSZEISSReveal ImagingSaiernicoASEMASEMAdvantechANSALDOELproMARCONIEBMPAPSTROTORKKONGSBERGSOCAPELTAIYOSUNYorkKURODAADLINKNotifierHBMInfineonLNICSaipwellJIANGYIN ZHONGHEW.E.ST. ElektronikEXPODEEP SEA ELECTRONICSBECKHOFFBOMBARDIER TRANSPORTATIONDragerZENTRO ELEKTRONIKATOSTRSystemtechnikJDS UniphaseADEPTREOPanametricsXenusSIGMATEK DIASS.C.E ElettronicaEKFETELSTOBER POSIDYNHANSHINDDKEITZENBERGERLTI MOTIONXP PowerPanasonicMatroxSBS TechnologiesWARTSILAMURPHYMADOKAArcnet DanpexLittelfuseTACANHurcoSAMGONGALPHALuxcoNautibusPAWO SystemsHaver&boeckerVAISALAConsiliumSERIPLEXMTUALPHIOPTIMATION INCNTRONNIDECTMEIC GLOBALBAUMERSANYO-DENKISeicaISE ReiterSealICP ELECTRONICSAxiomtekBautzSonosysVaconNematronWatt DriveSieb & MeyerDanaher MotionDEMAGDigifasDivusBühlerRMV ELECTRONICSOno SokkiOrbotechPLATING ELECTRONICNORD NORDACDematicCircuit LineBergesAIENSNBAUMULLERSZMCHATILLONACS GROUPADVANTESTSekidenkoDOLDTURCKAPI ControlsASAHI KEIKIQUALIFLOWASMLASTROCOGNEXContecESTICFishmanIAITeleFrankInternixAUMAPROVIBTECHK-TRONLemforderIXYSALERTONMOXA

- Select

-

21500 TDXnet Transient3300 System3500 System330400 and 330425 Accelerometer190501 Velomitor CT Transducer200150, 200155 and 200157 Accelerometers990 and 991 Transmitter31000 and 32000 Proximity Probe Housing Assemblie21000, 24701, and 164818 ProbeHousing Assemblies177230 Seismic TransmitterTK-3 Proximity System330500 and 330525 Piezo-Velocity Sensor7200 Proximity Transducer SystemsIEPE Accelerometer Series170180 FieldMonitor External Transducer I/O Module330525 Series330750 and 330752 High Temperature Velomitor1900 Vibration Monitor3701 Machinery Dynamics Monitor24765 and 135613 Case Expansion1701 FieldMonitor Proximitor Input Monitor2300 Vibration Monitors9200 and 74712 Seismoprobe Velocity Transducers3300 XL 8mm Proximity Transducer3300 XL Proximity Transducer3300 XL 11mm Proximity Transducer3300 XL NSV Proximity Transducer1900/65 General Purpose Equipment Monitor

-

- Advant Controller 31 Advant Controller 110/160 Advant Controller 250 Master MOD 300 AC500 AC800F AC800M S100 I/O S200 I/O S400 I/O S800 I/O AC800F-Freelance S900 I/O 800PEC

- ACS 100 ACS 150 ACS 200 ACS 310 ACS 400 ACS 55 ACS 600 ACS 850 Stromberg ACS 140 ACS 160 ACS 300 ACS 355 ACS 500 ACS 550 ACS 800 DCS 800 Accessories ACS 580 ACS 1000 ACS880 MotiFlex e180 ACS 380

-

-

-

- MICROMASTER 1st Generation MICROMASTER 2nd Generation MICROMASTER 3rd Generation MICROMASTER 410/420/430/440 MICROMASTER Junior

- S5-090/095/100 S5-010 S5-101 S5-105 S5-110 S5-115 S5-130/150 S5-135/155 S5-210 S5 Memory S5 Simatic Net S5 Intelligent Processors S5 HMI S5 Batteries CPU100 CPU103 S5-150U CPU101 CPU110 S5-095U S5-135U (exc. PS) S5-155U (excl PS) CPU102 Moby S5-100U S5-150S rack

- C7 ET 200B ET 200C ET 200eco ET 200 ISP ET 200L ET 200M ET 200pro ET 200R ET 200S ET 200X M7-300 M7-400 S7 Simatic Net S7-1200 S7-200 S7-300 S7-400 S7-Batteries S7 HMI S7-Memory Simatic Box PC Simatic DP Simatic PG/Programming Simatic SC ET 200ISP ET 200SP S7-HMI Simatic Panel PC/Box PC Moby S7-1500 SITOP ET 200AL Simatic S7

All Categories

-

990 Vibration TransmitterManufacturer: Bently Nevada

990 Vibration TransmitterManufacturer: Bently Nevada -

3300 XL 11 mm Proximity ProbesManufacturer: Bently Nevada

3300 XL 11 mm Proximity ProbesManufacturer: Bently Nevada -

3300 XL 11 mm Extension CableManufacturer: Bently Nevada

3300 XL 11 mm Extension CableManufacturer: Bently Nevada -

3300 XL 11 mm Proximity ProbesManufacturer: Bently Nevada

3300 XL 11 mm Proximity ProbesManufacturer: Bently Nevada -

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada -

3300 XL 11 mm Proximity ProbesManufacturer: Bently Nevada

3300 XL 11 mm Proximity ProbesManufacturer: Bently Nevada -

3300 XL 8 mm ProbeManufacturer: Bently Nevada

3300 XL 8 mm ProbeManufacturer: Bently Nevada -

Interconnect CableManufacturer: Bently Nevada

Interconnect CableManufacturer: Bently Nevada -

3300 XL 8 mm ProbeManufacturer: Bently Nevada

3300 XL 8 mm ProbeManufacturer: Bently Nevada -

Proximity System Test KitManufacturer: Bently Nevada

Proximity System Test KitManufacturer: Bently Nevada -

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada -

990 Vibration TransmitterManufacturer: Bently Nevada

990 Vibration TransmitterManufacturer: Bently Nevada -

3300 XL Standard Extension CableManufacturer: Bently Nevada

3300 XL Standard Extension CableManufacturer: Bently Nevada -

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada -

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada -

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada -

Velomitor Piezo-velocity SensorManufacturer: Bently Nevada

Velomitor Piezo-velocity SensorManufacturer: Bently Nevada -

3300 XL 11 mm Proximitor SensorManufacturer: Bently Nevada

3300 XL 11 mm Proximitor SensorManufacturer: Bently Nevada -

3300 XL 11 mm Proximity ProbesManufacturer: Bently Nevada

3300 XL 11 mm Proximity ProbesManufacturer: Bently Nevada -

190501 Velomitor CT TransducerManufacturer: Bently Nevada

190501 Velomitor CT TransducerManufacturer: Bently Nevada -

990 Vibration TransmitterManufacturer: Bently Nevada

990 Vibration TransmitterManufacturer: Bently Nevada -

3300 XL 8 mm Reverse Mount ProbesManufacturer: Bently Nevada

3300 XL 8 mm Reverse Mount ProbesManufacturer: Bently Nevada -

3300 XL 8 mm Reverse Mount ProbesManufacturer: Bently Nevada

3300 XL 8 mm Reverse Mount ProbesManufacturer: Bently Nevada -

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada -

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada

3300 XL 8 mm Proximity ProbesManufacturer: Bently Nevada

Ensure Machinery Reliability with Bently Nevada Spare Parts

Maintaining the health of your critical rotating machinery depends on the integrity of your monitoring systems. This page offers a complete inventory of Bently Nevada components, essential for ensuring your Turbine Supervisory Instrumentation (TSI) operates flawlessly. Access to the correct TSI spare parts is the key to preventing costly, unplanned downtime and maintaining operational safety. We provide a full spectrum of new and obsolete Bently Nevada parts to keep your most valuable assets protected and productive.

Precision Monitoring with Foundational Sensors

The accuracy of any machinery protection system starts with its sensors. Our inventory includes a vast selection of TSI sensors engineered for precision and resilience in demanding industrial settings. A cornerstone of any TSI system is the Bently Nevada 3300 XL 8mm Proximity Sensor (330101-00-10-05-02-00). This non-contacting transducer leverages eddy current technology to deliver exceptionally accurate measurements of shaft vibration and axial position. The quality of this data is fundamental to all machinery health analysis. Using genuine Bently Nevada sensors guarantees that your monitoring modules receive clean, reliable signals, which is non-negotiable for effective asset protection.

Core Protection and Advanced Diagnostic Modules

The Bently Nevada 3500 system is the global standard for machinery protection, and we stock the critical I/O modules required to maintain its peak performance. A key component available here is the 3500/42M Proximitor/Seismic Monitor (3500/42M-01-00-00). This powerful four-channel module processes signals from both proximity and seismic sensors, providing continuous protection by comparing real-time data against configured setpoints.

For deeper diagnostic insights, the 3500/25 Enhanced Keyphasor Module (3500/25-01-02-00) is indispensable. A Keyphasor sensor provides a once-per-turn timing reference that is crucial for synchronous data analysis. This module conditions the signal, enabling your analysts to accurately diagnose complex faults such as imbalance and misalignment. Beyond these, we stock specialized modules, including various gas turbine cards, to support the unique requirements of specific machine applications.

Seamless System Integration and Communication

Connecting machinery protection data with plant-wide control systems requires robust and reliable communication hardware. The 3500/92 Communication Gateway (3500/92-01-01-00) is designed specifically for this task. The 3500 monitoring system is a trusted solution for continuous online surveillance and protection of critical rotating machinery. It tracks key parameters such as vibration, position, and temperature to detect early signs of equipment issues, reduce unplanned downtime, and support reliable, long-term operation across industrial facilities.

Browse our extensive inventory to find the exact Bently Nevada component for your needs. Whether you are performing routine maintenance, planning a system upgrade, or responding to an urgent outage, having access to high-quality spares is critical. Our stock covers new, and hard-to-find parts for systems including the 3300, 3500, and more. If you cannot locate a specific component or require assistance with compatibility, our expert team is ready to help you source the right solution quickly.

FAQs

-

What is Bently Nevada used for?+Its products are used to monitor the mechanical condition of rotating equipment in a wide variety of industries including oil and gas production, hydroelectric, wind, hydrocarbon processing, electric power generation, pulp and paper, mining, water and wastewater treatment.

-

What kind of sensors does Bently Nevada offer?+With nine million sensors installed worldwide, Bently Nevada condition monitoring solutions include a portfolio of sensors such as hydro sensors, pressure sensors, proximity sensors, velocity sensors, torque sensors and temperature sensors, transmitters, and accelerometers and wireless condition monitoring sensors

-

How does a vibration sensor work?+Vibration sensors can utilize displacement sensors or accelerometers to detect the magnitude (displacement, velocity, acceleration) and period (frequency) of vibrations. Accelerometers can measure both periodic acceleration acting on an object and constant (DC) acceleration such as gravitational acceleration.

-

How does a proximity sensor work?+A proximity sensor often emits an electromagnetic field or a beam of electromagnetic radiation (infrared, for instance), and looks for changes in the field or return signal. The object being sensed is often referred to as the proximity sensor's target. Different proximity sensor targets demand different sensors.

-

What are the benefits of condition monitoring?+Reduces unnecessary maintenance costs: Protects assets. More efficient maintenance: Schedules maintenance only when necessary. Avoids unplanned downtime: Prevents unexpected failures. Provides 'always-on' monitoring: Continuous asset monitoring.

-

What information is needed to ensure part compatibility?+To guarantee a perfect match, please provide our team with the complete part number from your component. If possible, include details about the system it belongs to. Our specialists will cross-reference all specifications for you.

-

Can I find obsolete or hard-to-find Bently Nevada parts here?+Yes. Our inventory is specifically curated to include not only current-production components but also a wide range of legacy and obsolete TSI spare parts, ensuring support for Bently Nevada systems of all generations.

-

What if I cannot identify the part number on my component?+If the part number is unreadable, send our team clear photographs of the component, making sure to capture any visible labels, tags, or distinguishing marks. Our experts can use our extensive database to identify the correct replacement part for you.

Bently Nevada

Comprehensive plantwide condition monitoring and protection systems.

We are Bently Nevada Supplier. We offer a plant-wide protection hardware, sensor, probes products that help you achieve the highest level of asset reliability possible.

- 21500 TDXnet Transient

- 3300 System

- 3500 System

- 330400 and 330425 Accelerometer

- 190501 Velomitor CT Transducer

- 200150, 200155 and 200157 Accelerometers

- 990 and 991 Transmitter

- 31000 and 32000 Proximity Probe Housing Assemblie

- 21000, 24701, and 164818 ProbeHousing Assemblies

- 177230 Seismic Transmitter

- TK-3 Proximity System

- 330500 and 330525 Piezo-Velocity Sensor

- 7200 Proximity Transducer Systems

- IEPE Accelerometer Series

- 170180 FieldMonitor External Transducer I/O Module

- 330525 Series

- 330750 and 330752 High Temperature Velomitor

- 1900 Vibration Monitor

- 3701 Machinery Dynamics Monitor

- 24765 and 135613 Case Expansion

- 1701 FieldMonitor Proximitor Input Monitor

- 2300 Vibration Monitors

- 9200 and 74712 Seismoprobe Velocity Transducers

- 3300 XL 8mm Proximity Transducer

- 3300 XL Proximity Transducer

- 3300 XL 11mm Proximity Transducer

- 3300 XL NSV Proximity Transducer

- 1900/65 General Purpose Equipment Monitor

990 Vibration Transmitter

05 0-5 mils pp (0-125 μm pp)

50 5.0 meters (16.4 feet)

01 35 mm DIN rail clips

05CSA Division 2, ATEX Zone 0

ATEXZone 2 and includes

ABSmaritime approval

3300 XL 11 mm Proximity Probes

330701 3300 XL 11 mm Probe

1/2-20 UNFthread, without armor

Minimum length:30 mm

10 1.0 meter (3.3 feet)

02 Miniature coaxial ClickLocconnector

standard cable

05 Multiple Approvals

3300 XL 11 mm Extension Cable

040 4.0 meters (13.1 feet)

02 Standard cable with connectorprotector

00 Not required

3300 XL 11 mm Proximity Probes

330709 3300 XL 11 mm Probe

M16 x 1.5 thread,without armor

Minimum length:130 mm

10 1.0 meter (3.3 feet)

02 Miniature coaxial ClickLocconnector

standard cable

00 Not required

3300 XL 8 mm Proximity Probes

330103 3300 XL 8 mm Probe

M10 x 1 thread,without armor

Minimum case length: 110 mm

10 1.0 meter (3.3 feet)

02 Miniature coaxial ClickLocconnector

standard cable

00 Not required

3300 XL 11 mm Proximity Probes

330709 3300 XL 11 mm Probe

M16 x 1.5 thread,without armor

Minimum length: 30 mm

10 1.0 meter (3.3 feet)

02 Miniature coaxial ClickLocconnector

standard cable

00 Not required

3300 XL 8 mm Probe

330104 3300 XL 8 mm Probe

M10 x 1 thread,with armor

Minimum unthreaded length: 80 mm

Minimum case length: 140 mm

05 0.5 meter (1.6 feet)

01Miniature coaxial ClickLocconnector

with connectorprotector, standard cable

00 Not required

Interconnect Cable

Conductors:3 twisted pairs (6 conductors)

Wire Gauge:24 AWG stranded copper

Shielding:Dual-layer:

Individual foil per pair

Overall tinned copper braid (95% coverage)

Impedance:100 Ω ±10% (1 kHz)

Capacitance:≤30 pF/ft (pair-to-pair)

Max Voltage:300 V AC/DC (continuous)

Resistance:≤25 Ω/1000 ft (per conductor)

3300 XL 8 mm Probe

330104 3300 XL 8 mm Probe

M10 x 1 thread,with armor

Minimum unthreaded length:10 mm

Minimum case length: 80 mm

50 5.0 meters (16.4 feet)

01Miniature coaxial ClickLocconnector

with connectorprotector, standard cable

05 CSA, ATEX, IECEx Approvals

Proximity System Test Kit

177313-02-02-00

PROXIMITY SYSTEM TEST KIT

TK-3E

1 AMP

95-250 VAC

50/60 HZ

90 PSI (6.2 BAR)

3300 XL 8 mm Proximity Probes

330104 3300 XL 8 mm Probe

M10 x 1 thread,with armor

Minimum case length: 50 mm

20 2.0 meters (6.6 feet)

02 Miniature coaxial ClickLocconnector

standard cable

05 CSA, ATEX, IECEx Approvals

990 Vibration Transmitter

05 0-5 mils pp (0-125 μm pp)

70 7.0 meters (23.0 feet)

03 DIN clips and screws

05CSA Division 2, ATEX Zone 0

ATEXZone 2 and includes

ABSmaritime approval

3300 XL Standard Extension Cable

3300 XL Standard Extension Cable

085 8.5 meters (27.9 feet)

03 Armored cable with connectorprotector

00 Not required

3300 XL 8 mm Proximity Probes

330104 3300 XL 8 mm Probe

M10 x 1 thread,with armor

Minimum unthreaded length: 20 mm

Minimum case length: 80 mm

05 0.5 meter (1.6 feet)

01Miniature coaxial ClickLocconnector

with connectorprotector, standard cable

00 Not required

3300 XL 8 mm Proximity Probes

330104 3300 XL 8 mm Probe

M10 x 1 thread,with armor

Minimum unthreaded length: 70 mm

Minimum case length: 140 mm

05 0.5 meter (1.6 feet)

01Miniature coaxial ClickLocconnector

with connectorprotector, standard cable

00 Not required

3300 XL 8 mm Proximity Probes

330104 3300 XL 8 mm Probe

M10 x 1 thread,with armor

Minimum unthreaded length: 20 mm

Minimum case length: 90 mm

05 0.5 meter (1.6 feet)

01Miniature coaxial ClickLocconnector

with connectorprotector, standard cable

00 Not required

Velomitor Piezo-velocity Sensor

04 1/4-20 UNC

04 Multiple approvals (CSA, ATEX)

Velomitor Piezo-velocity Sensor

3300 XL 11 mm Proximitor Sensor

51 5.0 meter (16.4 feet) systemlength

DIN mount

05 Multiple approvals

3300 XL 11 mm Proximity Probes

330701 3300 XL 11 mm Probe

1/2-20 UNFthread, without armor

Minimum unthreaded length:0.0 in

Minimum case length: 1.5 in

10 1.0 meter (3.3 feet)

02 Miniature coaxial ClickLocconnector

standard cable

05 Multiple Approvals

190501 Velomitor CT Transducer

07 Plate Stud 3/8-in 24 to 3/8-in 24

00 MIL-C-5015 connection interface

04CSA/NRTL/C

Velomitor CT Velocity Transducer

990 Vibration Transmitter

05 0-5 mils pp (0-125 μm pp)

70 7.0 meters (23.0 feet)

01 35 mm DIN rail clips

00 Not required

3300 XL 8 mm Reverse Mount Probes

330101 3300 XL 8 mm Probe

3/8-24 UNFthread, without armor

Minimum unthreaded length:3.3 in

Minimum case length: 5.3 in

10 1.0 meter (3.3 feet)

12 Miniature coaxial ClickLocconnector

FluidLoc cable

05 CSA, ATEX, IECEx Approvals

3300 XL 8 mm Reverse Mount Probes

330105-02-12-CC-DD-EE3/8-24 UNF threads

15 1.5 meter (4.9 feet)

12 Miniature ClickLoc coaxialconnector

FluidLoc cable

05 CSA, ATEX, IECEx Approvals

3300 XL 8 mm Proximity Probes

330101 3300 XL 8 mm Probe

3/8-24 UNFthread, without armor

Minimum unthreaded length: 1.6 in

Minimum case length: 2.8 in

10 1.0 meter (3.3 feet)

12 Miniature coaxial ClickLocconnector

FluidLoc cable

05 CSA, ATEX, IECEx Approvals

3300 XL 8 mm Proximity Probes

330101 3300 XL 8 mm Probe

3/8-24 UNFthread, without armor

Minimum unthreaded length: 0.0 in

Minimum case length: 1.0 in

10 1.0 meter (3.3 feet)

02 Miniature coaxial ClickLocconnector

standard cable

00 Not required

Ensure Machinery Reliability with Bently Nevada Spare Parts

Maintaining the health of your critical rotating machinery depends on the integrity of your monitoring systems. This page offers a complete inventory of Bently Nevada components, essential for ensuring your Turbine Supervisory Instrumentation (TSI) operates flawlessly. Access to the correct TSI spare parts is the key to preventing costly, unplanned downtime and maintaining operational safety. We provide a full spectrum of new and obsolete Bently Nevada parts to keep your most valuable assets protected and productive.

Precision Monitoring with Foundational Sensors

The accuracy of any machinery protection system starts with its sensors. Our inventory includes a vast selection of TSI sensors engineered for precision and resilience in demanding industrial settings. A cornerstone of any TSI system is the Bently Nevada 3300 XL 8mm Proximity Sensor (330101-00-10-05-02-00). This non-contacting transducer leverages eddy current technology to deliver exceptionally accurate measurements of shaft vibration and axial position. The quality of this data is fundamental to all machinery health analysis. Using genuine Bently Nevada sensors guarantees that your monitoring modules receive clean, reliable signals, which is non-negotiable for effective asset protection.

Core Protection and Advanced Diagnostic Modules

The Bently Nevada 3500 system is the global standard for machinery protection, and we stock the critical I/O modules required to maintain its peak performance. A key component available here is the 3500/42M Proximitor/Seismic Monitor (3500/42M-01-00-00). This powerful four-channel module processes signals from both proximity and seismic sensors, providing continuous protection by comparing real-time data against configured setpoints.

For deeper diagnostic insights, the 3500/25 Enhanced Keyphasor Module (3500/25-01-02-00) is indispensable. A Keyphasor sensor provides a once-per-turn timing reference that is crucial for synchronous data analysis. This module conditions the signal, enabling your analysts to accurately diagnose complex faults such as imbalance and misalignment. Beyond these, we stock specialized modules, including various gas turbine cards, to support the unique requirements of specific machine applications.

Seamless System Integration and Communication

Connecting machinery protection data with plant-wide control systems requires robust and reliable communication hardware. The 3500/92 Communication Gateway (3500/92-01-01-00) is designed specifically for this task. The 3500 monitoring system is a trusted solution for continuous online surveillance and protection of critical rotating machinery. It tracks key parameters such as vibration, position, and temperature to detect early signs of equipment issues, reduce unplanned downtime, and support reliable, long-term operation across industrial facilities.

Browse our extensive inventory to find the exact Bently Nevada component for your needs. Whether you are performing routine maintenance, planning a system upgrade, or responding to an urgent outage, having access to high-quality spares is critical. Our stock covers new, and hard-to-find parts for systems including the 3300, 3500, and more. If you cannot locate a specific component or require assistance with compatibility, our expert team is ready to help you source the right solution quickly.

Need an automation or control part quickly?

- Q&A

- Policies How to order Part status information Shiping method Return Policy Warranty Policy payment terms

- Asset Recovery

- We Buy Your Equipment. Industry Cases Press Releases Technical Resources

- ADDRESS

-

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

32D UNITS,GUOMAO BUILDING,NO 388 HUBIN SOUTH ROAD,SIMING DISTRICT,XIAMEN

Copyright Notice © 2004-2026 amikong.com All rights reserved

Disclaimer: We are not an authorized distributor or distributor of the product manufacturer of this website, The product may have older date codes or be an older series than that available direct from the factory or authorized dealers. Because our company is not an authorized distributor of this product, the Original Manufacturer’s warranty does not apply.While many DCS PLC products will have firmware already installed, Our company makes no representation as to whether a DSC PLC product will or will not have firmware and, if it does have firmware, whether the firmware is the revision level that you need for your application. Our company also makes no representations as to your ability or right to download or otherwise obtain firmware for the product from our company, its distributors, or any other source. Our company also makes no representations as to your right to install any such firmware on the product. Our company will not obtain or supply firmware on your behalf. It is your obligation to comply with the terms of any End-User License Agreement or similar document related to obtaining or installing firmware.

Cookies

Individual privacy preferences

-

Google Tag Manager

-

Functional cookies